Bit like me reallyNo it’s not illuminating when turned on

Bit like me reallyNo it’s not illuminating when turned on

I’ve just tried what @DSR recommended, I set my meter to 200V place one lead on the earth clamp and the other on the tip of the gun. Without pressing the trigger i was getting a reading of 10.4, when I pressed the trigger, the relay clicks and transformer powers up, with a reading of 23.2, I then turned the speed knob up and down multiple times but the motor still stayed idleThis has changed since I was last here. Good that the new SCR is in and bad that it hasn't solved the problem.

I'd hesitate to recommend a new controller simply because of the cost and the fact the the existing controller looks to be undamaged and working - the relay wouldn't click if the transformer had burnt out and you have replaced the SCR with new.

Hutcho and I suggested the wire speed pot - I thought it looked out of position and not flat.

Set your meter to the 200V range, plug the red lead into the right plug marked with a diode symbol, AV and ω and your black lead into the middle connector probably marked common. Connect the other end of the test leads to the earth clamp and the tip of the torch. It may be easier to connect them to the + & - terminals inside the welder...

Power on the welder and press the trigger, the relay should click in and the main transformer power up. You should see a reading on the meter when you do this - I don't know what it is but it I would expect something in the range of 18-40V. If you see 0V, then check your meter is working, also check that you have properly made the connections. We know that you get good current out because you have struck an arc between the cables so you should see a voltage reading, if you don't your meter is at fault or your rectifier is at fault and you are getting AC out instead of DC - try measuring the voltage on the 200V AC range (4 clicks to the right on your meter from the 200VDC position) If you get a voltage reading on AC but not DC your rectifier could be faulty and this could be the source of the problem.

Once you have a known good voltage out, keep the torch button depressed and swing the wire speed knob from min to max and back a few times and see if the motort starts to rotate. At the same time see if you can tell if it feels different to before the damage - i.e. is it tighter than you remember or much looser or just the same, is there a catch at it moves - it could indicate a broken track in the pot etc. If there is no movement of the motor, it all feels smooth and you have a good voltage out then the problem could lie with the controller board BUT it could also lie with an incorrectly placed wire, a missing wire or a broken wire.

At this point, turn the welder off and disconnect the mains power then start having a good look inside the case at all the wires. Check that there are none floating about and disconnected, check that none are snapped or damaged - give them a gentle tug to see if the come away from their terminal etc.

Do you have photos of the inside before you took it to bits - if so have a really good look and compare them with what you have, make sure the wires are on the same way and in the same place as before.

It's a pain to go through, one wire at a time, as you check each wire, mark them with a felt pen as you check each end off etc. to be methodical.

I'd pay particular attention to the wires that come from the rectifier to the PCB - they could well be on the wrong way round. The circuit diagram appears to show there is a diode on the board that will prevent current flowing to the motor if the wires are back to front on the rectifier. The circuit diagram doesn't show great detail of the PCB so this is only an educated guess. If you don't have photos, ask on the forum - somebody somewhere will have a good quality pic of the insides :-)

If this doesn't solve the problem, you are at the point of looking at a new PCB, getting to a shop for servicing or re-purposing the welder - they make good door stops or an interesting focal point for your coffee table

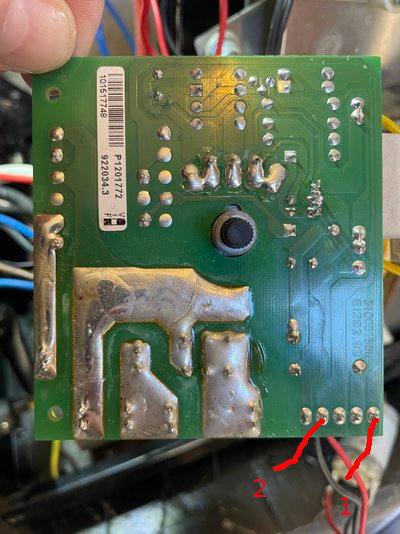

The red & black wires on top of the rectifier seems on and okay, I’ve attached some more pics for you to guys to dig into

I’ve just tried what @DSR recommended, I set my meter to 200V place one lead on the earth clamp and the other on the tip of the gun. Without pressing the trigger i was getting a reading of 10.4, when I pressed the trigger, the relay clicks and transformer powers up, with a reading of 23.2, I then turned the speed knob up and down multiple times but the motor still stayed idle

Nice & easy this one@DSR which setting is it on my meter for the 200ohm setting? Apologies I’ve never really used a meter before

Different numbers again

Positive was -01.9

Negative was -01.4

option

option