You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CNC machines

- Thread starter ned

- Start date

ned

Member

- Messages

- 954

- Location

- Eire

This is one of the outer corners. This is probabl;y the best one. I am using Oerlikon Citorex 3.2mm rods and I find they make me look better than I am.

I've never made a watertight vessel before - this looks pretty watertight?

Are arc welds ever porous? I've only ever seen porosity with mig

I've never made a watertight vessel before - this looks pretty watertight?

Are arc welds ever porous? I've only ever seen porosity with mig

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,134

- Location

- France, Brittany.

Arc welds can be porous, but that looks fine to me.This is one of the outer corners. This is probabl;y the best one. I am using Oerlikon Citorex 3.2mm rods and I find they make me look better than I am.

View attachment 300207

I've never made a watertight vessel before - this looks pretty watertight?

Are arc welds ever porous? I've only ever seen porosity with mig

It sounds a bit like a tuning fork

Don't go all Riverdance on us, please.

ned

Member

- Messages

- 954

- Location

- Eire

Got the floor welded in. 32 feet of weld. Skip welded it: 3 inches of weld, 12 inches gap, let it set overnight, repeat for 2 weeks odd.

Sooo, that went well. It was fun I loved it. So,, the next thing is getting the rails on and cutting the spacers for the rails, then welding in the spacers for the rails, then building new gantry plates because mine are too low.

I bought paint, need to finish welding. I bought a new blade for my good saw, and I've been trying to get it square using a piece of thin wall 100x100 box. 15 cuts and its still not square. I have one side good, so I am near.

I came across the Proma Myplasm controller and THC, plasma cutting for idiots it says on the box, so I'm selling stuff to buy that controller. And then I might actually finish the thing.

Sooo, that went well. It was fun I loved it. So,, the next thing is getting the rails on and cutting the spacers for the rails, then welding in the spacers for the rails, then building new gantry plates because mine are too low.

I bought paint, need to finish welding. I bought a new blade for my good saw, and I've been trying to get it square using a piece of thin wall 100x100 box. 15 cuts and its still not square. I have one side good, so I am near.

I came across the Proma Myplasm controller and THC, plasma cutting for idiots it says on the box, so I'm selling stuff to buy that controller. And then I might actually finish the thing.

ned

Member

- Messages

- 954

- Location

- Eire

I sold my Gerber Sabre 408 for a song and now I can afford the Myplasm CNC for idiots setup. Let this be considered a live review.

BY the way I'm getting evicted from my glorious shed, We are having to move. So expect delays. Gonna see what I can get done though. I'm having gantry plates machined using 10mm aluminum. Gotta design them. I want to use the motors inboard.

I'm looking at 20 foot containers as a new workshop.

BY the way I'm getting evicted from my glorious shed, We are having to move. So expect delays. Gonna see what I can get done though. I'm having gantry plates machined using 10mm aluminum. Gotta design them. I want to use the motors inboard.

I'm looking at 20 foot containers as a new workshop.

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,134

- Location

- France, Brittany.

What thickness will it cut ?I sold my Gerber Sabre 408 for a song and now I can afford the Myplasm CNC for idiots setup. Let this be considered a live review.

James1979

Member

- Messages

- 8,434

- Location

- Orkney

Everyone asks this about mine when they are making enquiries about work.What thickness will it cut ?

What I believe they need to ask is how fine can it cut and what’s the thinnest it’ll cut without distorting. I do more thin intricate stuff than thick plate. The thick stuff tends to be easier to do the thicker it gets - gussets, flitch plates, foot plates for beam etc etc.

Just my 2p

good to see you’ve bought something Ned, following with interest.

Hood

I am obsessed.

- Messages

- 17,456

- Location

- Carnoustie, Scotland

Thicker stuff tends to be easier because you cut slower.

Thinner material is easier if your table is capable of high speeds but also it has to have high acceleration or you will get corner rounding. If your table is not capable of the higher feed/Accel then the other option is to reduce the current and nozzle size but often it will still not be enough for some tables.

Thinner material is easier if your table is capable of high speeds but also it has to have high acceleration or you will get corner rounding. If your table is not capable of the higher feed/Accel then the other option is to reduce the current and nozzle size but often it will still not be enough for some tables.

ned

Member

- Messages

- 954

- Location

- Eire

Cheers guys.

The thinnest material I use is 3mm.

I bought motors this morning., The guy I sold the Gerber to, and his dad, are CNC nuts, the dad has a cnc plasma cutter. Anyways point being, I can put questions to them, which is good because I need all the help I can get.

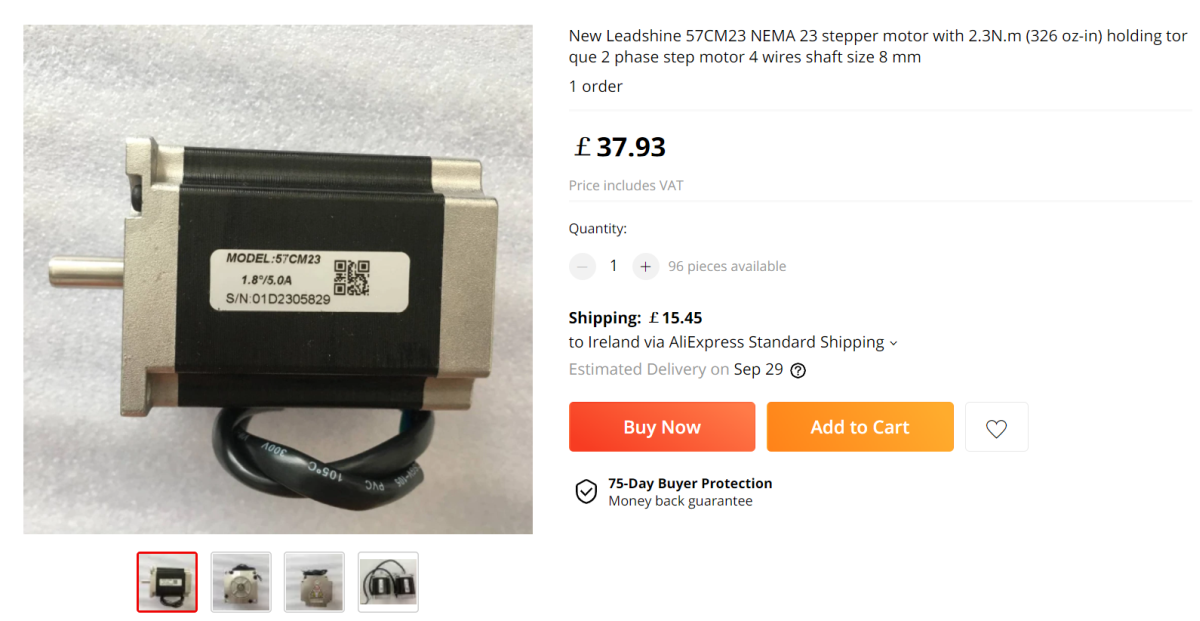

I bought stepper motors this morning. According to the two fellas, 200 oz-in steppers would have been fine, so I went a bit higher than that. I'll make it nippy eventually, for right now I just want it to work at all.

www.aliexpress.com

www.aliexpress.com

The thinnest material I use is 3mm.

I bought motors this morning., The guy I sold the Gerber to, and his dad, are CNC nuts, the dad has a cnc plasma cutter. Anyways point being, I can put questions to them, which is good because I need all the help I can get.

I bought stepper motors this morning. According to the two fellas, 200 oz-in steppers would have been fine, so I went a bit higher than that. I'll make it nippy eventually, for right now I just want it to work at all.

New Leadshine 57CM23 NEMA 23 stepper motor with 2.3N.m (326 oz-in) holding torque 2 phase step motor 4 wires shaft size 8 mm - AliExpress 13

Smarter Shopping, Better Living! Aliexpress.com

Ned__

Member

- Messages

- 58

- Location

- Eire

I go one of the rails attached. There was a lot or work in the brackets, but, they look really tidy in the flesh, surprisingly so.

I made friends with a guy who's built three CNC plasmas, which is big. You ask a question on the internet you get 5 - 10 different possible solutions, whereas I can ask questions to him and get one answer that is based on experience.

Not dissing the internet, never think it. Just can be hard to know which solution to go for.

I made friends with a guy who's built three CNC plasmas, which is big. You ask a question on the internet you get 5 - 10 different possible solutions, whereas I can ask questions to him and get one answer that is based on experience.

Not dissing the internet, never think it. Just can be hard to know which solution to go for.

MattH

Member

- Messages

- 4,524

- Location

- Cornwall

Cheers guys.

The thinnest material I use is 3mm.

I bought motors this morning., The guy I sold the Gerber to, and his dad, are CNC nuts, the dad has a cnc plasma cutter. Anyways point being, I can put questions to them, which is good because I need all the help I can get.

I bought stepper motors this morning. According to the two fellas, 200 oz-in steppers would have been fine, so I went a bit higher than that. I'll make it nippy eventually, for right now I just want it to work at all.

New Leadshine 57CM23 NEMA 23 stepper motor with 2.3N.m (326 oz-in) holding torque 2 phase step motor 4 wires shaft size 8 mm - AliExpress 13

Smarter Shopping, Better Living! Aliexpress.comwww.aliexpress.com

View attachment 305033

Higher torque steppers will actually slow it down. They have higher inductance that limits the rise and fall time of each coil which in turn limits the max speed. This can be overcome to a certain extent by using a higher drive voltage i.e. a 200Oz/inch motor might be fine with 24v but a 300Oz/inch might need 36v.

Remember thin sheet is going to take a lot more speed to cut well than thicker stuff.

I've been down this road and ended up with two Fibre laser cutters.

Hood

I am obsessed.

- Messages

- 17,456

- Location

- Carnoustie, Scotland

I would use ServosIf I was building that I'd be using Rack and Pinion with Nema42 hybrid steppers (1200-1600 Oz/per) with belt reductions of at least 5:1.

MattH

Member

- Messages

- 4,524

- Location

- Cornwall

I would use Servos

Indeed, as mine does. But even 400W AC servos are a massive step up from Hybrid Steppers yet alone standard steppers.

Even with 400W servos with planetary gearboxes I struggled with getting the speeds high enough for 1.5mm MS, I could of gone down the route of swapping out to 750w servos which I had but even then large hybrid steppers would of been a better choice.

I've seen the servos on your plasma, no one builds a table with servos that powerful for under £50K!

Hood

I am obsessed.

- Messages

- 17,456

- Location

- Carnoustie, Scotland

I reckon 400w servos with reduction would be more than enough for a plasma. Only reason I used bigger is because I had them.

The servos ae getting very cheap nowadays and I was almost tempted to get a few sets as spares, just £2-300 for a drive, motor and 30m cables.

The servos ae getting very cheap nowadays and I was almost tempted to get a few sets as spares, just £2-300 for a drive, motor and 30m cables.

Ned__

Member

- Messages

- 58

- Location

- Eire

I went with the steppers out of sheer desperation, ive gone in multiple wrong directions with this build and at this stage just want the fastest route to the finish line, which does seem to be rapidly approaching, thankfully.

I will switch to servos but down the line, for now I just want to get it moving and maybe even making some money.

Hood what servos were you looking at? Was looking at servos last night.

Matt I have 48v power supply for the steppers.

I will switch to servos but down the line, for now I just want to get it moving and maybe even making some money.

Hood what servos were you looking at? Was looking at servos last night.

Matt I have 48v power supply for the steppers.

MattH

Member

- Messages

- 4,524

- Location

- Cornwall

I reckon 400w servos with reduction would be more than enough for a plasma. Only reason I used bigger is because I had them.

The servos ae getting very cheap nowadays and I was almost tempted to get a few sets as spares, just £2-300 for a drive, motor and 30m cables.

They're not. Rapids are fine, easily 15M/min but the acceleration is to low, anything above 0.9G introduces to much jerk and are 0.9G the direction changes are way to slow (for 1.5mm) and cause overburn and arc wander.

On 5mm thick and upwards they are great but thin needs loads of speed.