You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

compressor sound proofing

- Thread starter pondy

- Start date

The Buddah

I'm using phone for internet.

- Messages

- 307

hope this is the right section, I will be starting this project in the new year but after some advice before I get started.

I have a little 50l, twin piston direct drive compressor, its in my garage which is in a block for the people in our close, my garage backs onto someone elses garden, I have only been here for 7 months and don't want to annoy my neighbours, its also to loud I usually get out the garage when its on, I downloaded a decibel app on my phone and measured it at 86db.

compressor

View attachment 40010

airline etc

View attachment 40011

the compressor sits under my work bench, I plan to build a wooden frame around the compressor then board it off with mdf or ply wood and have a door at the front so I can get the compressor and turn it on and off and drain water etc. all the joins would be sealed up with silicone sealant and a small rubber seal around the inside of the door so I closes tight with no gaps?

I want to line the inside with some sort of sound proofing but unsure whats best? I have never delt with anything like this before so just searched sound proofing on ebay and it brings up products like this

http://www.ebay.co.uk/itm/Acoustic-..._Acoustic_Treatments&var=&hash=item51ab415a0a

can be sprayed with adhesive and stick to all sides, roof and door, does any one have any experience with this product or anything like it?

my biggest thing is going to be ventilation and cooling. I have a few of these in my 'random bits box'

View attachment 40012

I could place one low down at the back of the box which would such in cool air and one high up on the door which would let warm air vent out from. there is a large van on the back of the compressor which sucks air in and blows in over the pump, problem being I don't want this box to take up to much space and at the moment I run the compressor hard against the wall, this fan is then around 1 inch off the wall, is this a problem? I was thinking of getting a bathroom extractor fan to put into the side of the box with the flexible ducting to direct cool at the back of this fan?

I want to remove the small air filter from the heads, and with the fittings and some hose running outside the box and mounted on the wall so I don't draw in warm air inside the box which will cause more water inside the tank? I need to find out what size the fittings need to be in the head, I know after using a gauge from my tap and die set that the pitch is 1.50, and my calipers show an external diameter of 15mm, it this a normal size?

View attachment 40017

View attachment 40019

one last thing for the time being in the hight of the box, the compressor stands 60 cm tall, my work bench that its under stands 95cm tall. I could build the box tight to the top of the compressor and have a little storage area on top or I could build the box right up to the bottom of my work bench is the top, giving me around 35cm of area for hot area to rise to and vent out, any input on that's best? Im thinking more of the second option

The Buddah

I'm using phone for internet.

- Messages

- 307

Hi,

Would you mind giving me a reveiw of your compressor?

I noticed your compressor, is it any good and does it run off a standard plug?

Im looking to purchase a compressor but its a minefield out there.

I want to restore my car, sandblast and spray parts.

I've seen one similar to what you have there for £210 with some tools, its a 50ltr 14cfm and im considering buying it.

Thank you for any help you can provide.

Would you mind giving me a reveiw of your compressor?

I noticed your compressor, is it any good and does it run off a standard plug?

Im looking to purchase a compressor but its a minefield out there.

I want to restore my car, sandblast and spray parts.

I've seen one similar to what you have there for £210 with some tools, its a 50ltr 14cfm and im considering buying it.

Thank you for any help you can provide.

brightspark

Member

- Messages

- 40,158

- Location

- yarm stockton on tees

Hi,

Would you mind giving me a reveiw of your compressor?

I noticed your compressor, is it any good and does it run off a standard plug?

Im looking to purchase a compressor but its a minefield out there.

I want to restore my car, sandblast and spray parts.

if your going to sandblast id recomend buying a belt drive compressor. for constant running u will kill a direct drive setup . a mate of mine borrowed a fairly new clarke one and bu...ered it up blasting . fortunately machine mart replaced it under waranty

The Buddah

I'm using phone for internet.

- Messages

- 307

Maybe i'll just use the drill with a rust remover wheel instead.

Whats that compressor like you have?

Whats that compressor like you have?

brightspark

Member

- Messages

- 40,158

- Location

- yarm stockton on tees

i have a twin setup 28cfm comp and a home made 14cfm comp. to be honest if im using it for blasting it will run for an hour or so and get red hot . it will just get flogged till it packs inMaybe i'll just use the drill with a rust remover wheel instead.

Whats that compressor like you have?

a new pumps only about 100 quid

a new pumps only about 100 quidThe Buddah

I'm using phone for internet.

- Messages

- 307

Sounds good.

Its just that your hyas compressor looks like one i was considering.

I like to ask people now because i have a habbit of buying crap tools....lol

Its just that your hyas compressor looks like one i was considering.

I like to ask people now because i have a habbit of buying crap tools....lol

pondy

Member

- Messages

- 1,627

- Location

- chedburgh, suffolk. uk

Its spot on for my needs, the only thing wrong is the noise! You can run it from a 13a plug. these small compressors are for diy use so anything that uses lots of air like blasting and even a ratchet is a no go as the pump cant supply enough air to run it constantly, the duty cycle is only 40% also

The Buddah

I'm using phone for internet.

- Messages

- 307

Hi Pondy,

Hows the sound insulation on your compressor holding up?

Good thead by the way.

Any soft surface that will absorb vibration will reduce sound thats why rockwool is good because it is more flexible than foam. If you go into a local recording studio they will have the old style egg boxes on the wall due to the fact they break up the sound waves and are soft.

Hows the sound insulation on your compressor holding up?

Good thead by the way.

Any soft surface that will absorb vibration will reduce sound thats why rockwool is good because it is more flexible than foam. If you go into a local recording studio they will have the old style egg boxes on the wall due to the fact they break up the sound waves and are soft.

The Buddah

I'm using phone for internet.

- Messages

- 307

I purchaed a small belt drive 5.5hp petrol, it seems loud, so i'll insuate it a little at some point but i'd like it to be mobile.

There were a few problems to start with but i've had it running and it took 8 mins to fill the 50L tank.

The next thing will be to ad another air tank.

Gareth J

Member

- Messages

- 3,497

- Location

- North Cornwall

Nice project and great write up thread. I used to work with industrial cooling so will add my 2pth. That you have considered the cooling and ducting so well is great, you'd be surprised how many intelligent folk never give it a thought. A few questions with your setup as I understand it though; how well sealed is the inlet of the fan to the duct you have created? If there is chance for air to seep past here, it will increase temps. Also, is that a 4" duct for the inlet? I'd think that might be a bit restrictive, what's the open area of the motor fan inlet? I'd be looking at using ducting 1.5x the area of the fan inlet. If you negatively pressurise the inlet duct too much, you risk slowing airflow and encouraging leaks into it from the hot side. If it runs ok, then all good but if you do decide it needs some alteration, as you've done such a smart job on the construction, the easiest mod would be to add a decent flow rate fan on the box inlet/outlet.

I creased myself looking at that pic . just thinking how i did mine with some carpet and two old internal doors with honey comb in . lol respect to you mate respect.

pondy

Member

- Messages

- 1,627

- Location

- chedburgh, suffolk. uk

Why don't you get a fridge motor/compressor and replace the current motor with that? The fridge motor/compressor is very quiet.

My friend has a home made compressor with a fridge compressor,takes ages to fill up and due to it being so quite when I used it to plasma cut the take would get low on pressure as it could not keep up.

Nice project and great write up thread. I used to work with industrial cooling so will add my 2pth. That you have considered the cooling and ducting so well is great, you'd be surprised how many intelligent folk never give it a thought. A few questions with your setup as I understand it though; how well sealed is the inlet of the fan to the duct you have created? If there is chance for air to seep past here, it will increase temps. Also, is that a 4" duct for the inlet? I'd think that might be a bit restrictive, what's the open area of the motor fan inlet? I'd be looking at using ducting 1.5x the area of the fan inlet. If you negatively pressurise the inlet duct too much, you risk slowing airflow and encouraging leaks into it from the hot side. If it runs ok, then all good but if you do decide it needs some alteration, as you've done such a smart job on the construction, the easiest mod would be to add a decent flow rate fan on the box inlet/outlet.

It's 4" ducting which are is mounted close to the fan inlet, its alot smaller than the fan on the compressor so not ideal. I tested using some paper towel infront of the inlet grille and it does suck the paper so it is doing something, same happerns with the exhaust ducting. I have not had any issues with it in the last year, Im making metal roses at the moment so was plasma cutting for around an hour and although it got hot I did not activate the thermal trip. batteries flat in thermometer so I'm unsure what temp it got up too. I gets hotter after being used then sitting due to hear rising from pump and no airflow, when I'm not cutting or having a break I usually leave the door open. Would be a good idea to add a fan to remove this heat. It stays cool down the bottom on the enclosure so I relocated airfilters down here.

I creased myself looking at that pic . just thinking how i did mine with some carpet and two old internal doors with honey comb in . lol respect to you mate respect.

Thank you

pondy

Member

- Messages

- 1,627

- Location

- chedburgh, suffolk. uk

Bringing up an old thread.

Doing some work on my compressor and want to address somthing that's been bothering me which is heat, I have been using the compressor for longer periods of time with the plasma cutter. When the compressor runs its not Much of a problem due to the fan, when compressor sits for a bit after heavy use the pump gives of a lot of heat.

I have brought a shower extractor fan of eBay for £6 posted and looking for ideas how to fit it into the box to remove heat from the top of the box without taking up to much space or letting sound get out?

Doing some work on my compressor and want to address somthing that's been bothering me which is heat, I have been using the compressor for longer periods of time with the plasma cutter. When the compressor runs its not Much of a problem due to the fan, when compressor sits for a bit after heavy use the pump gives of a lot of heat.

I have brought a shower extractor fan of eBay for £6 posted and looking for ideas how to fit it into the box to remove heat from the top of the box without taking up to much space or letting sound get out?

Gareth J

Member

- Messages

- 3,497

- Location

- North Cornwall

It would be quieter drawing air, located inline in the inlet duct at the bottom/back. But more effective with your setup as I understand it in the exhaust duct at the top.

How about a couple PC fans across the exhaust/top? They're super quiet and so long as you don't ask them to try to work too hard, push a fair bit of air...

How about a couple PC fans across the exhaust/top? They're super quiet and so long as you don't ask them to try to work too hard, push a fair bit of air...

pondy

Member

- Messages

- 1,627

- Location

- chedburgh, suffolk. uk

I was thinking more of having it sucking the hot air out rather than pulling cool air in? It's not somthing I had planned on running a lot, maybe just under heavy use or switch on between breaks etc?

There is not a lot of room for it, options I can see it a fan inside at the top and some ducting into my exhaust duct.

or to make a new intake duct out of steel with a 200mm opening which will fit tight to the compressor fan instead of a 100mm hose near the back? Then run a duct from the top of the box and have it exit out the side?

There is not a lot of room for it, options I can see it a fan inside at the top and some ducting into my exhaust duct.

or to make a new intake duct out of steel with a 200mm opening which will fit tight to the compressor fan instead of a 100mm hose near the back? Then run a duct from the top of the box and have it exit out the side?

pondy

Member

- Messages

- 1,627

- Location

- chedburgh, suffolk. uk

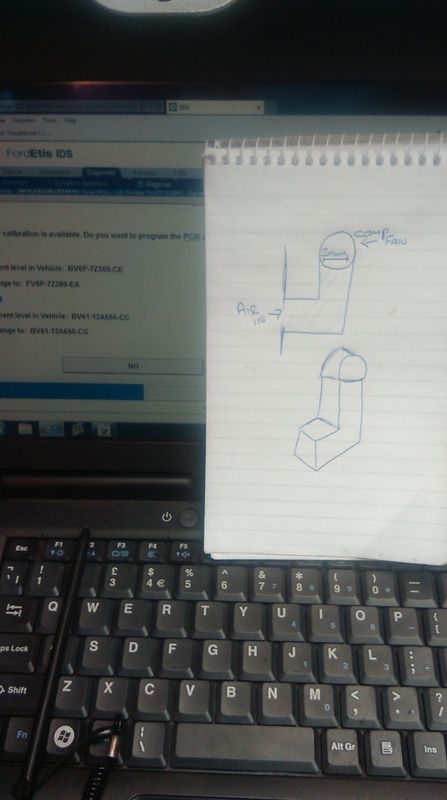

Quick/ rough sketch while I had a spare min at work of the idea I have for new I take. Basically I larger metal duct that will replace the 100mm hose and will fit much closer to the compressors own fan. Worried being 1mm steel is might vibrate or resonate noise? Won't touch compressor but was going to put to 15mm pipe lagging on the duct to seal gap more?

Extractor fan I plan to mount in top of box with ducting going I a vent outside of box, vent with have flaps on to try and stop noise when fan not in use.

Am I over thinking of this?

Gareth J

Member

- Messages

- 3,497

- Location

- North Cornwall

Am I over thinking of this?

Maybe. As you said it is running almost ok now, it'd probably be ok anywhere - even just inside the box creating a bit of circulation. All I was getting at is that fans are generally quieter on the "pull" side than the "push" side. If its not to be used often, I recon somewhere in the exhaust would be most effective.

I recon your setup will be quieter than my welder on tickover!