- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- CAD/CAM, 3D Printing and Laser Cutting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Could someone print this.

- Thread starter Hood

- Start date

Kram

Member

- Messages

- 8,371

- Location

- Sussex

As your panel is ABS (+ PE, the mix gives better durability I believe?) it would be ideal to solvent weld with acetone or MEK slurry, if you can avoid using the repair for a week for it to fully harden. If you have the original clip it can be stuck back on with extra reinforcement.

I'd cut layers of ABS sheet and butter them together with mek slurry. I've made tool battery adaptors and rebuilt my smashed cbr6 fairing like this. Ones its dry, ahould be good and flexible as the original. its one of the most common plastics so easy to find stuff to make slurry with.

As you have it modeled, glue up some abs sheet into a block then cnc mill it? You cant seem to buy it as a solid block

Acetone should harden up quicker.

Superglue will give a brittle bond, wont last for that sort of repair IMO. Epoxy will work its far more brittle than abs, likely to peel off.

I'd cut layers of ABS sheet and butter them together with mek slurry. I've made tool battery adaptors and rebuilt my smashed cbr6 fairing like this. Ones its dry, ahould be good and flexible as the original. its one of the most common plastics so easy to find stuff to make slurry with.

As you have it modeled, glue up some abs sheet into a block then cnc mill it? You cant seem to buy it as a solid block

Acetone should harden up quicker.

Superglue will give a brittle bond, wont last for that sort of repair IMO. Epoxy will work its far more brittle than abs, likely to peel off.

Hood

I am obsessed.

- Messages

- 17,982

- Location

- Carnoustie, Scotland

@Bladevane has kindly made a couple for me so we will see how it goes.

Ti's easy.....if you use ABS Pro from steady tech. (And a slurry from pure ABS)We dream of (successfully) printing ABS here! One day...

Sadly I can't find it any more.

I have a decent supply of it all be it in Natural or Gold colours....so if no one else manages it send me the STL.

Yep I have access to a Stratasys F370 who’s material properties start at ABS and go up from thereTi's easy.....if you use ABS Pro from steady tech. (And a slurry from pure ABS)

Sadly I can't find it any more.

I have a decent supply of it all be it in Natural or Gold colours....so if no one else manages it send me the STL.

MoreWellie

Forum Supporter

- Messages

- 1,884

- Location

- Warwickshire, UK

ABS is a good idea, my youngest printed some car speaker mounts in the standard stuff PET? and they majorly deformed once the sun shone. He has since reprinted in ABS and they have so far retained their shapeNeeding someone who could print this in ABS

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,079

- Location

- Sevenoaks, UK

ABS is a good idea, my youngest printed some car speaker mounts in the standard stuff PET? and they majorly deformed once the sun shone. He has since reprinted in ABS and they have so far retained their shape

Same here. Mine would print a new PLA phone holder nearly everytime he borrowed the car!

PETG now not as good as ABS but better than PLA.

Given the loading and shape, I'd print it on edge, so you're not solely relying on layer adhesion for strength.I would go for option 1 - the solid. It will need supports somewhere. I'm thinking to print it upside down. Let's get the model first and work out the detail from that.

Standard is normally PLA.ABS is a good idea, my youngest printed some car speaker mounts in the standard stuff PET? and they majorly deformed once the sun shone. He has since reprinted in ABS and they have so far retained their shape

PETG is normally good enough for in car stuff.

Hood

I am obsessed.

- Messages

- 17,982

- Location

- Carnoustie, Scotland

To be fair there won't be much stress on this at all as the panel clips in all around and really I am not sure why they have it there.

I don't know when it got broken, I suspect when the tracker was fitted as no one else has had any reason to remove that panel other than me and I didn't brake it. If it was when the tracker was fitted then that would be over a month ago so probably at least 800 miles has been covered since then. There were also a few other bits done at tracker fitting time which I wasn't to happy about, the bracket that holds the fuse box on was snapped but fortunately I have been able to glue it, also a bolt was missing but when I had the tank removed to run the camera wires I found it under there.

Anyway we will see how things go with the ones @Bladevane has kindly done and take it from there.

I don't know when it got broken, I suspect when the tracker was fitted as no one else has had any reason to remove that panel other than me and I didn't brake it. If it was when the tracker was fitted then that would be over a month ago so probably at least 800 miles has been covered since then. There were also a few other bits done at tracker fitting time which I wasn't to happy about, the bracket that holds the fuse box on was snapped but fortunately I have been able to glue it, also a bolt was missing but when I had the tank removed to run the camera wires I found it under there.

Anyway we will see how things go with the ones @Bladevane has kindly done and take it from there.

MoreWellie

Forum Supporter

- Messages

- 1,884

- Location

- Warwickshire, UK

It was pla that he used that deformed badly. Definitely abs that he used that has been ok since

He tried a digital thermometer and it was reaching 50+ degrees but then the LCD display went patchy on his thermometer as it got too hot itself

Hood

I am obsessed.

- Messages

- 17,982

- Location

- Carnoustie, Scotland

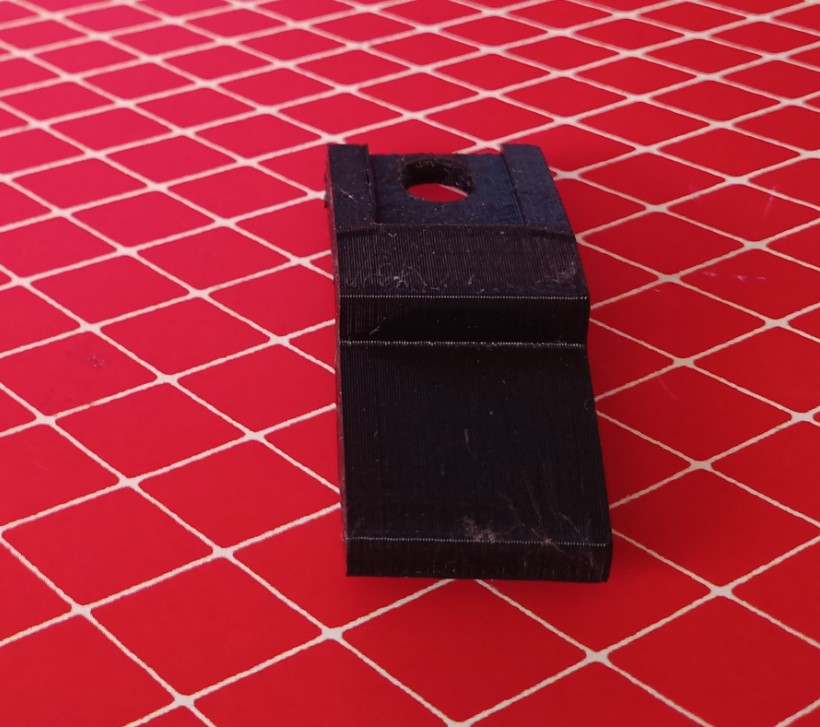

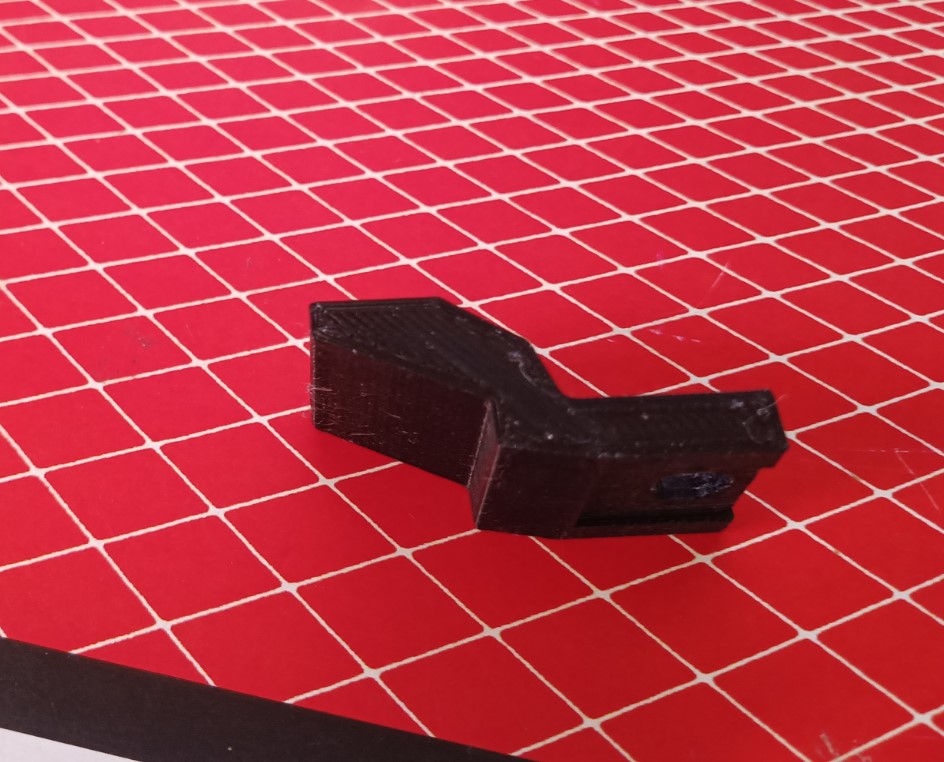

The printed parts arrived today, much appreciated and there was not just one but 5 prototypes and 5 final prints which are much better quality than I would have thought possible.

Some pics.

Took the panel off and tried some superglue, it seemed to work.

Sadly when assembling and trying to fit the button head it popped up so I will have to get some acetone tomorrow and give that a go. Good thing however is they are a perfect fit and the threaded clip lines up exactly with the hole in the underside plastic so if the acetone works then I should be good to go.

Thanks again @Bladevane, much appreciated.

Some pics.

Took the panel off and tried some superglue, it seemed to work.

Sadly when assembling and trying to fit the button head it popped up so I will have to get some acetone tomorrow and give that a go. Good thing however is they are a perfect fit and the threaded clip lines up exactly with the hole in the underside plastic so if the acetone works then I should be good to go.

Thanks again @Bladevane, much appreciated.

Hood

I am obsessed.

- Messages

- 17,982

- Location

- Carnoustie, Scotland

Got a chance to try the acetone and I didn't think it was going to work as it hardly seemed to touch the printed part. It did act well on the ABS however so I gave it a try. It seems to have worked, let it sit overnight and now if I try and prise it off the panel bends and I think it would likely break the panel before it separates so very happy with the result

Once again big thanks to @Bladevane

Once again big thanks to @Bladevane

That's good as superglue is also affected by water.Got a chance to try the acetone and I didn't think it was going to work as it hardly seemed to touch the printed part. It did act well on the ABS however so I gave it a try. It seems to have worked, let it sit overnight and now if I try and prise it off the panel bends and I think it would likely break the panel before it separates so very happy with the result

Once again big thanks to @Bladevane

I have just glued a part of my binoculars back together with Wilko Hard Plastic glue, (dropped them!) seems very good for whatever plastic they are made of (probably ABS but not marked so).