- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CPMT inserts?

- Thread starter Kram

- Start date

Not at home mate.The ones I sent should fit, no?

Photo of what arrived?

I had these before I got the bar..in fact that why I grabbed. I thought being left handed it would be pointing left..but I learnt today I have been wrong all along. Lol

Kram

Member

- Messages

- 7,447

- Location

- Sussex

I cant get this boring bar to work. New, proper cpmt09t308 inserts do

not improve over the modified ccmt's. Any cut deeper than 0.4mm diameter gives bad chatter, hot chips and possibly rubbing but marker pen isnt showing where. Inserts wont be the problem but I'll try them in the sclcr bar with a shim in pocket to rule it out.

It must be intended for 0903 inserts as t3's have a slight 0.07mm clearance in the pocket which Ive sorted with copper shim, but should make no difference.

Stickout makes no difference so the carbide shank is good. I might unbraze the end, or tig up the pocket and cut a new one.

My 12mm carbide SDQCR bar beats this in every way.. £60 wasted, never going to use it as it is.

Without knowing why, Im not sure what to do with it. The modified ccmt's should have worked with the bar rotated over 15 degrees.

not improve over the modified ccmt's. Any cut deeper than 0.4mm diameter gives bad chatter, hot chips and possibly rubbing but marker pen isnt showing where. Inserts wont be the problem but I'll try them in the sclcr bar with a shim in pocket to rule it out.

It must be intended for 0903 inserts as t3's have a slight 0.07mm clearance in the pocket which Ive sorted with copper shim, but should make no difference.

Stickout makes no difference so the carbide shank is good. I might unbraze the end, or tig up the pocket and cut a new one.

My 12mm carbide SDQCR bar beats this in every way.. £60 wasted, never going to use it as it is.

Without knowing why, Im not sure what to do with it. The modified ccmt's should have worked with the bar rotated over 15 degrees.

Rkweld

Member

- Messages

- 406

- Location

- Kent England

Silly question, is the lathe rotating the right directionI cant get this boring bar to work. New, proper cpmt09t308 inserts do

not improve over the modified ccmt's. Any cut deeper than 0.4mm diameter gives bad chatter, hot chips and possibly rubbing but marker pen isnt showing where. Inserts wont be the problem but I'll try them in the sclcr bar with a shim in pocket to rule it out.

It must be intended for 0903 inserts as t3's have a slight 0.07mm clearance in the pocket which Ive sorted with copper shim, but should make no difference.

Stickout makes no difference so the carbide shank is good. I might unbraze the end, or tig up the pocket and cut a new one.

My 12mm carbide SDQCR bar beats this in every way.. £60 wasted, never going to use it as it is.

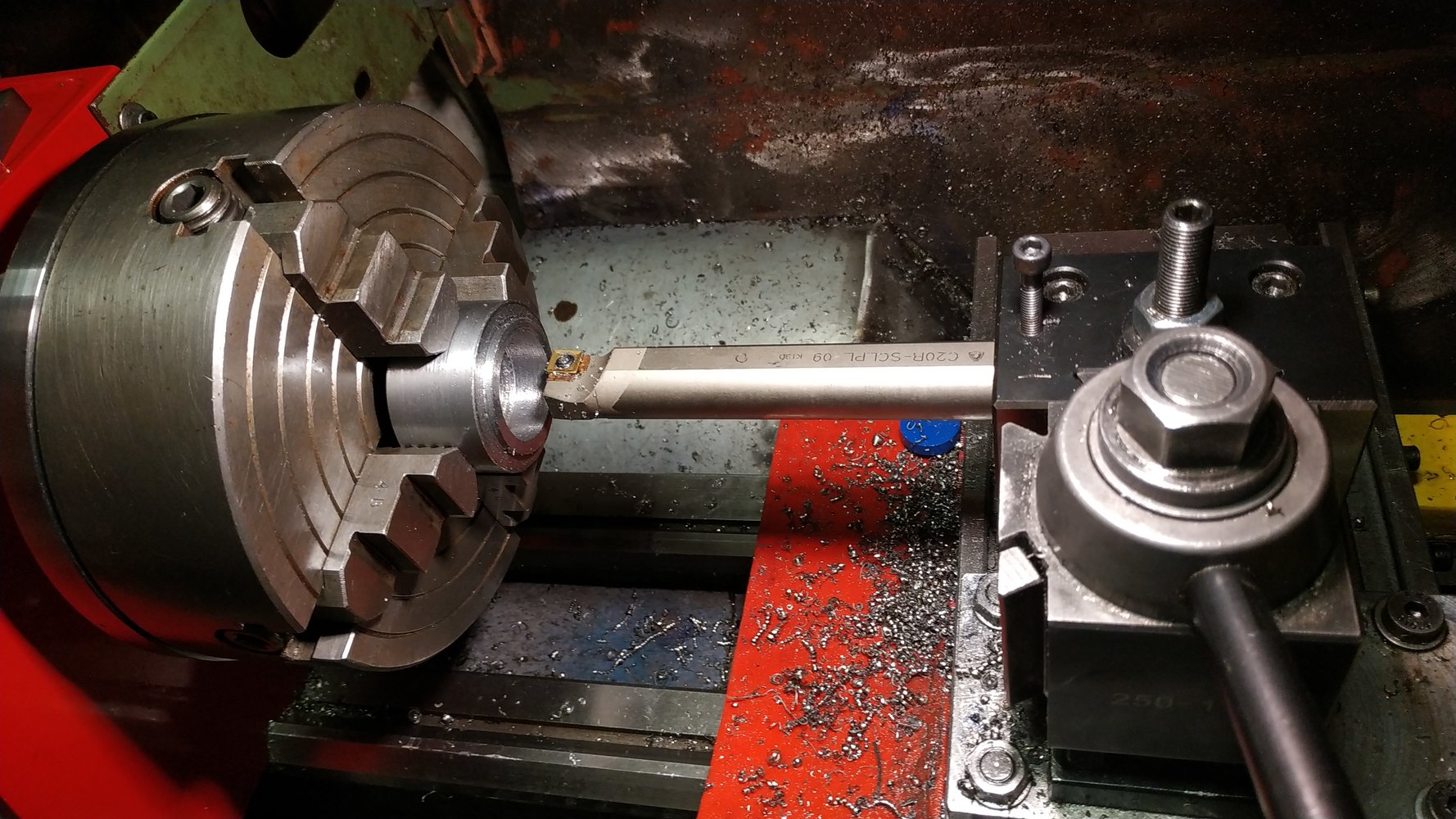

View attachment 308982

Without knowing why, Im not sure what to do with it. The modified ccmt's should have worked with the bar rotated over 15 degrees.

View attachment 309000

Kram

Member

- Messages

- 7,447

- Location

- Sussex

I wish it were that simple! I have forgotten the rotation switch a couple of times going back to normal turning.

@Brad93 the 09 insert size on this is not ideal, 0602's chip breakers are much better suited on a small machine. If I remake the pocket it will be for DCMT0702's. Bigger shank size is always better if it fits the bore.

@RichardM with 25-50mm bore on the other bars , I get best results 500-1500 rpm. High as it will go with a decent cut and no chatter.

Ive tried it slow, while it will take small cuts without chatter the finish is rough and a lot worse than the others will do.

Ebay didnt give much choice for the cpmt's. My sclcr09 bars work with the chinese 08's. Gives me something to try - I'll modify a ccmt09t302 to fit and try rotated over. I'll try a copper shim to fit a new insert in a sclcr bar and see how that works.0.8 nose rad is too much for that bar in my opinion, 0.4 would work much better.

@Brad93 the 09 insert size on this is not ideal, 0602's chip breakers are much better suited on a small machine. If I remake the pocket it will be for DCMT0702's. Bigger shank size is always better if it fits the bore.

@RichardM with 25-50mm bore on the other bars , I get best results 500-1500 rpm. High as it will go with a decent cut and no chatter.

Ive tried it slow, while it will take small cuts without chatter the finish is rough and a lot worse than the others will do.

Kram

Member

- Messages

- 7,447

- Location

- Sussex

If you meant the picture, no, the grind is just for the pocket and the bar is rotated for the normal clearance angle. It should work, but something doesnt...

Tried new inserts in the s12-sclcr bar, small shim of copper to make a good fit. Its much better but not as good as cheap standard chinese ccmt09t308's. 300rpm and 2mm diameter cut. Not a great finish. They will need a bigger lathe to get the speed up and feed harder.

I think I'll list them on ebay.

Tried new inserts in the s12-sclcr bar, small shim of copper to make a good fit. Its much better but not as good as cheap standard chinese ccmt09t308's. 300rpm and 2mm diameter cut. Not a great finish. They will need a bigger lathe to get the speed up and feed harder.

I think I'll list them on ebay.

Hood

I am obsessed.

- Messages

- 17,467

- Location

- Carnoustie, Scotland

It shouldn't really matter with regards cutting as long as the geometry is presented correctly. It will however make a difference to the feed distance as it will not be consistent with the dial.When you rotate the bar are you setting the tip up to centre still or does that not matter?

8ob

Member

- Messages

- 14,049

- Location

- Nescient in the vale

It shouldn't really matter with regards cutting as long as the geometry is presented correctly. It will however make a difference to the feed distance as it will not be consistent with the dial.

Robin do these boring bars have a diameter range? As in does the rake of the tip need to change as the diameter of the piece being bored reduces?

Bob

Hood

I am obsessed.

- Messages

- 17,467

- Location

- Carnoustie, Scotland

The geometry of the bar/insert will be designed for the minimum boring dia of the bar.Robin do these boring bars have a diameter range? As in does the rake of the tip need to change as the diameter of the piece being bored reduces?

Bob

dan.taylor.1

General Tinkererer

- Messages

- 2,768

- Location

- Kendal, Cumbria

They usually have a minimum bore size that they will fit, not sure there is a maximumRobin do these boring bars have a diameter range? As in does the rake of the tip need to change as the diameter of the piece being bored reduces?

Bob

Hood

I am obsessed.

- Messages

- 17,467

- Location

- Carnoustie, Scotland

Just to add, what I was meaning when I said

Was because we were talking about rotating the tool to get the geometry correct due to the insert being the wrong geometry for the holder....as long as the geometry is presented correctly. ...

8ob

Member

- Messages

- 14,049

- Location

- Nescient in the vale

The geometry of the bar/insert will be designed for the minimum boring dia of the bar.

Would raising the tool a tad help in Krams situation ?

Bob

Hood

I am obsessed.

- Messages

- 17,467

- Location

- Carnoustie, Scotland

I think the answer is to get the correct inserts for the bar.Would raising the tool a tad help in Krams situation help?

Bob

I have an example from my own experience. I have a few wee Stellram boring bars and I bought a load of inserts to suit, or so I thought. Shape, size and clearance were correct but it seems the grind on the top was for left hand bars and mine were right hand. I thought the bars were very poor until I got a left hand bar and it cut beautifully, that was when I investigated further and found out about the grind of the chip breaker, I got the correct inserts and they now work beautifully. So nothing about the shape. size clearance was wrong with the inserts, just purely the chip breaker grind was wrong and that made the difference between a poor tool and a brilliant tool, so having the wrong shape/height/clearance is almost certainly not going to get you off to a good start.

Rkweld

Member

- Messages

- 406

- Location

- Kent England

I think the geometry will not be correct because as you take a cut the geometry will change. As the diameter increases though it may be giving you more clearance but you will get to a point when you begin to cut above your new effective center height. Is that correct? Although Krams problem is not solved, I am learning a lot so thanks everyone!Just to add, what I was meaning when I said

Was because we were talking about rotating the tool to get the geometry correct due to the insert being the wrong geometry for the holder.

Hood

I am obsessed.

- Messages

- 17,467

- Location

- Carnoustie, Scotland

I suppose technically the full geometry will not be correct unless you are using the correct insert in the correct holder and at the correct centre height. If you rotate the tool holder so that the insert has the proper clearance then it should work, but should and will are two different things as you also need to take into account the chip breaker which on a rotated tool may not be presenting itself to the material correctly, that may or may not matter too much as it will depend on the chip breaker.I think the geometry will not be correct because as you take a cut the geometry will change. As the diameter increases though it may be giving you more clearance but you will get to a point when you begin to cut above your new effective center height. Is that correct? Although Krams problem is not solved, I am learning a lot so thanks everyone!

What will definitely not be correct is the feed reading from the dial as the insert tip is now below centre and thus a feed on the X axis will not correspond to the material being removed, here is a quick sketch with exaggerated distances but it shows how the distance moved will not correspond to the material removed.