You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

cutting key ways

- Thread starter lotus 30

- Start date

lotus 30

classic car enthusiast mostly lotus

- Messages

- 714

- Location

- caldicot south wales uk

Thanks pete the crank end is 50mm hole and key way. The front drive for the prop is 19mm so correct me if i am wrong but the broach will not pass all the way through so i asume you would push the broach until it bottoms out and re shim until it has cut to the desired depth.Broaching in a lathe isn't that slow a process. If you take off just a couple of thou each pass that's only 63 passes to cut 1/8"

lotus 30

classic car enthusiast mostly lotus

- Messages

- 714

- Location

- caldicot south wales uk

I made a tool and done it on the lath I struggled for ages wondering what i was doing wrong i am not the best at sharpening tools but struggle i did then i looked at the original drive i was copying and there was a groove at the end of the keyway so i put the groove in and after all my struggling that made things a lot easier LOL

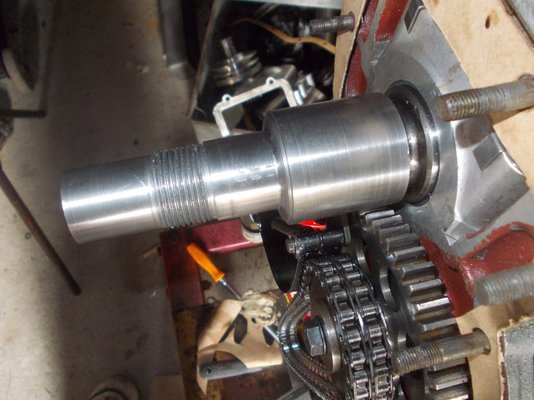

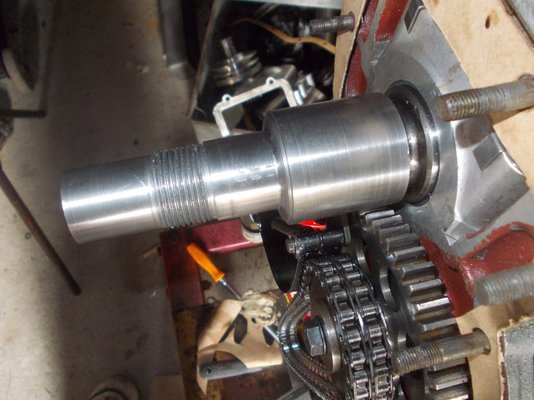

picture of the bit i have made a nice tight fit but you can pull it off and on by hand just so result thanks for all the tips andy

.

picture of the bit i have made a nice tight fit but you can pull it off and on by hand just so result thanks for all the tips andy

.

lotus 30

classic car enthusiast mostly lotus

- Messages

- 714

- Location

- caldicot south wales uk

brightspark

Member

- Messages

- 41,312

- Location

- yarm stockton on tees

ive done a couple with a chissel and verry accurate. no good if your in a hurry but good engineering practice the old wayyou can cut a keyway with a chisel, I don't recommend you do though if you can get it on a machine

doubleboost

Member

- Messages

- 3,904

- Location

- Newcastle upon Tyne England

lotus 30

classic car enthusiast mostly lotus

- Messages

- 714

- Location

- caldicot south wales uk

That will save a load of time i can see me making a couple of these as the engines were pinched out of boats and used in sports cars and the maranising parts were scrapped.Ive done a couple on the lathe in the past but both times, i spun up a top hat plug, and pre drilled the route of the keyway, so the broaching on the lathe only really squared off a half round groove.

lotus 30

classic car enthusiast mostly lotus

- Messages

- 714

- Location

- caldicot south wales uk

thanks for the tipOne can often be better off with drilling and reaming for a hardened tapered pin

Consider this if you are short of the correct gear for keyways

The reamer and pin come as a kit

Key way on this job is already in the crank and the prop drive so no choice with this one i did drill and put a round key to hold the camshaft gear drive.

much faster job. but these are the first key ways i have attempted now i have ground and made the tools it should be less time on the next one.

andy

addjunkie

Member

- Messages

- 14,203

- Location

- Northumberland. Reet oot in the sticks

Been a while since ive played with boat engines, been a marine engineer to trade, obviously i did a fair bit of it, these were mostly diesel big enough to squash a sports car and its factory. I did race bosts too for a while, was like burning 20 pound notes. And that was back in the 80s.

I blew up my 85 hp yam many times, trying to make it rev to 10000 revs. Towards the end of my power boating adventures, i was advised by a self made multi millionaire...if it flys, floats, or *****, it should be rented.

Are we talking old two stoke outboards or old v8s ith the merccruiser z drive stuck on the back.

A 200 hp v6 two stroke outboard, in a locost would be fun!

I blew up my 85 hp yam many times, trying to make it rev to 10000 revs. Towards the end of my power boating adventures, i was advised by a self made multi millionaire...if it flys, floats, or *****, it should be rented.

Are we talking old two stoke outboards or old v8s ith the merccruiser z drive stuck on the back.

A 200 hp v6 two stroke outboard, in a locost would be fun!

Last edited by a moderator:

addjunkie

Member

- Messages

- 14,203

- Location

- Northumberland. Reet oot in the sticks

Some friends of mine bought one of those, cheap, it would have been probably 84, fixed it up, got it going, had huge cooling problems, as some muppet used a great big nut in the eye of the centrifugal pump, sucking the water in.

I have in mind that it was a cortina engine, from memory.

A complete albertros would be quite collectable now, theres sank it wasnt designed to be out on rough water

I have in mind that it was a cortina engine, from memory.

A complete albertros would be quite collectable now, theres sank it wasnt designed to be out on rough water

addjunkie

Member

- Messages

- 14,203

- Location

- Northumberland. Reet oot in the sticks

Just done a quick albertros research, brought back some memories, of that sinking and the other daft things you did with over confidence, and bravardo, when young and daft.

Oh how we laughed, when it was swamped by the surf, went back at low tide and got the boat. Money and other interests meant it was never fixed again. Basically i went away to sea, the owner wasnt mechanically minded and it was never thought of again.

Must ask him what happened to the boat!

Oh how we laughed, when it was swamped by the surf, went back at low tide and got the boat. Money and other interests meant it was never fixed again. Basically i went away to sea, the owner wasnt mechanically minded and it was never thought of again.

Must ask him what happened to the boat!