Pete.

Member

- Messages

- 14,933

- Location

- Kent, UK

I picked this up today (9 hr round trip) set out at 4.30am and got back home about 3.30pm with the time it took to load etc. It's a Dowding and Doll gear hobbing machine. It's currently stripped down in the back of my van as I'm too knackered to unload it and it's raining anyway. Here's some pics of it from the seller's workshop before dismantling:

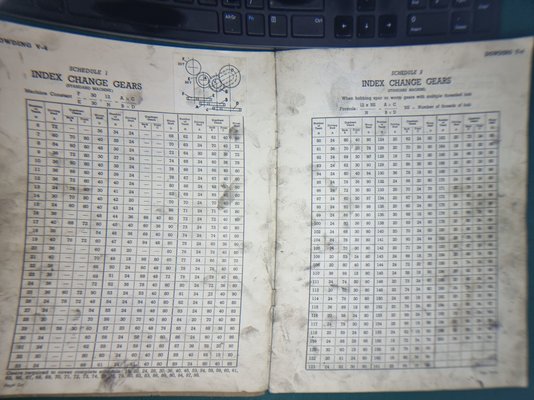

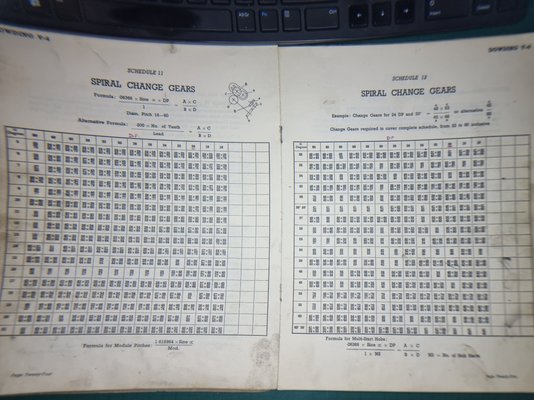

It (apparently, I haven't checked everything) comes with all of the bits that should come with the machine. A full set of change gears (3 or 4 different pitches for the different operations), a selection of gear holding arbors, a small selection of gear cutting hobs, and most importantly - the operating instructions. It also comes with the original list of parts from when it was delivered new to the customer (a technical college). It didn't come with any of the (probably very expensive) optional parts like the tangential/cross-feed head, which would allow for cutting high-helix worms like speedo drives etc, but they require a special hob (not to mention special knowledge) so I'm probably no worse off there.

Good bits - it apperars complete as above, fully working once it's cleaned and lubed. It's in excellent mechanical condition showing no wear at all. Apart from being a little gummy from long inactivity it's literally ready to plug in and work. Even the original paintwork is in great condition. I have no plans to rebuild or re-paint this machine (especially not bright green), it simply doesn't require it.

Not so good - well there's not much really. I have to check if the motor can be wired for delta, if not it's getting replaced with one that will and a VFD installed. I might even just fit a single phase one since the hob speed is set by change gears. The biggest bug-bear is that it uses a fairly uncommon size of cutter - 1/2" bore. I might be able to get over this by re-making the hob arbor, it looks like it might be removable from the spindle and if it is, that would be a good bonus becaus eI can make a new spindle to use my growing collection of 10mm bore hobs.

As far as work envelope goes it's very similar to the beautiful Mikron hobber I bought off @awemawson more than 5 years ago. The Mikron will actually cut gears a little larger (nearly 5" diameter where this one is a maximum of 4"). And the instructions for this one list up to 16DP whereas the Mikron lists up to 12DP MOD 2 hobs, though that really is pushing it. I think that this one will manage the same.

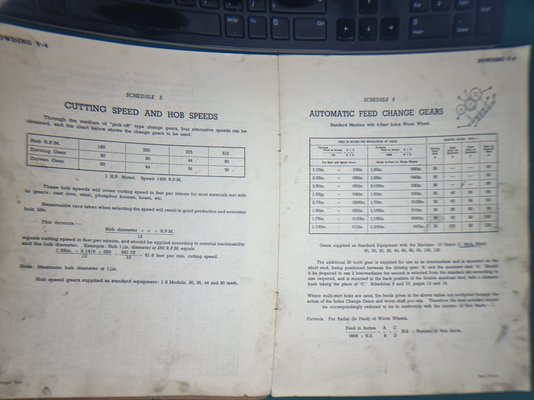

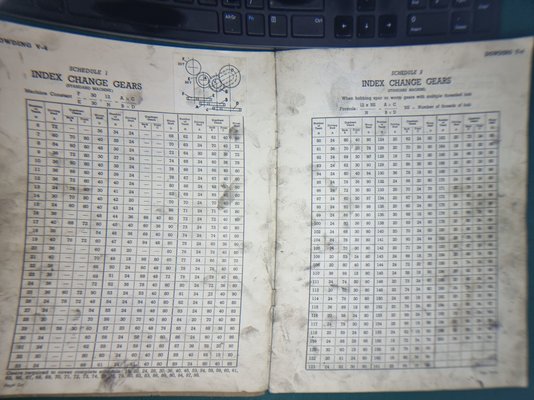

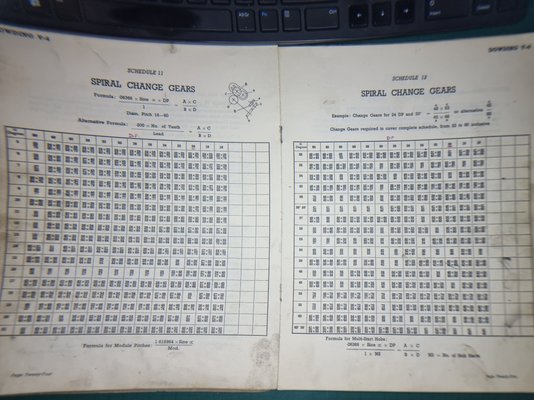

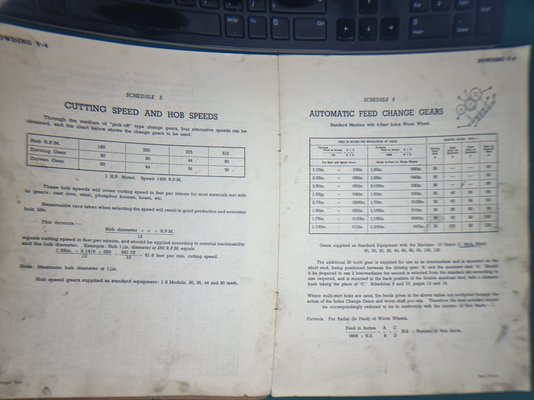

The one big advantage of this machine is that it has a 4-gear differential train which means that where the Mikron can cut only spur gears, this one can do both spur and helical gears. I'm glad I got the instruction manual for it though because there is a LOT of setup info in there that would be very hard to do without. Here's a few example pages, I'm going to have to set up a light box and scan it all in properly one day soon.

It (apparently, I haven't checked everything) comes with all of the bits that should come with the machine. A full set of change gears (3 or 4 different pitches for the different operations), a selection of gear holding arbors, a small selection of gear cutting hobs, and most importantly - the operating instructions. It also comes with the original list of parts from when it was delivered new to the customer (a technical college). It didn't come with any of the (probably very expensive) optional parts like the tangential/cross-feed head, which would allow for cutting high-helix worms like speedo drives etc, but they require a special hob (not to mention special knowledge) so I'm probably no worse off there.

Good bits - it apperars complete as above, fully working once it's cleaned and lubed. It's in excellent mechanical condition showing no wear at all. Apart from being a little gummy from long inactivity it's literally ready to plug in and work. Even the original paintwork is in great condition. I have no plans to rebuild or re-paint this machine (especially not bright green), it simply doesn't require it.

Not so good - well there's not much really. I have to check if the motor can be wired for delta, if not it's getting replaced with one that will and a VFD installed. I might even just fit a single phase one since the hob speed is set by change gears. The biggest bug-bear is that it uses a fairly uncommon size of cutter - 1/2" bore. I might be able to get over this by re-making the hob arbor, it looks like it might be removable from the spindle and if it is, that would be a good bonus becaus eI can make a new spindle to use my growing collection of 10mm bore hobs.

As far as work envelope goes it's very similar to the beautiful Mikron hobber I bought off @awemawson more than 5 years ago. The Mikron will actually cut gears a little larger (nearly 5" diameter where this one is a maximum of 4"). And the instructions for this one list up to 16DP whereas the Mikron lists up to 12DP MOD 2 hobs, though that really is pushing it. I think that this one will manage the same.

The one big advantage of this machine is that it has a 4-gear differential train which means that where the Mikron can cut only spur gears, this one can do both spur and helical gears. I'm glad I got the instruction manual for it though because there is a LOT of setup info in there that would be very hard to do without. Here's a few example pages, I'm going to have to set up a light box and scan it all in properly one day soon.