- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dowding and Doll V-4 gear hobber

- Thread starter Pete.

- Start date

Pete.

Member

- Messages

- 14,829

- Location

- Kent, UK

So, this evening I sorted through the piles of gears.

I have:

4no MOD2 hob speed gears

5no MOD2 ratio/reversing gears

36no MOD1.5 index gears

10no MOD1 feed change gears

59no MOD1 differential change gears

Which is exactly what should be with the machine. One of the gears (90T feed gear) has several damaged teeth but contrary to what I said befor eI don't think it's from engaging the direct feed drive and differential drive together but simply a matter of the gears being engaged too tightly on the banjo. Luckily it's a mod1 gear and the machine came with a mod1 hob so I can make a replaement.

I also discovered why the differential gears are called differential gears - they turn a differential:

I'm still trying to wrap my head around this but it seems that one side of the diff is driven at normal feed-rate speed and the other side is driven by the worm which adds in the bit extra you need to advance the blank according to the helical angle, and combined they'll cut the teeth at an angle.

I have:

4no MOD2 hob speed gears

5no MOD2 ratio/reversing gears

36no MOD1.5 index gears

10no MOD1 feed change gears

59no MOD1 differential change gears

Which is exactly what should be with the machine. One of the gears (90T feed gear) has several damaged teeth but contrary to what I said befor eI don't think it's from engaging the direct feed drive and differential drive together but simply a matter of the gears being engaged too tightly on the banjo. Luckily it's a mod1 gear and the machine came with a mod1 hob so I can make a replaement.

I also discovered why the differential gears are called differential gears - they turn a differential:

I'm still trying to wrap my head around this but it seems that one side of the diff is driven at normal feed-rate speed and the other side is driven by the worm which adds in the bit extra you need to advance the blank according to the helical angle, and combined they'll cut the teeth at an angle.

Snap....I thought the same..lolI thought that is a great bargain - then I saw they are £120 EACH

Pete.

Member

- Messages

- 14,829

- Location

- Kent, UK

Spent a couple of hours tonight doing my cleaning and oiling rounds. To get proper access I removed the hob spindle head, the collet block and the support arn and tailstock. I cleaned up the table slideway, removed the lock, cleaned all the gummy dried oil off it and put it back together, then I cleaned the hob carrier slideways so they all moved nice and smooth. Note all of the slideways are hand scraped and still show all the scraping.

Here's the revolving table, the bit that holds and turns the collet block for the gear blank arbor

Here's the drive gear and the bronze driven gear for the spindle. No wear to see.

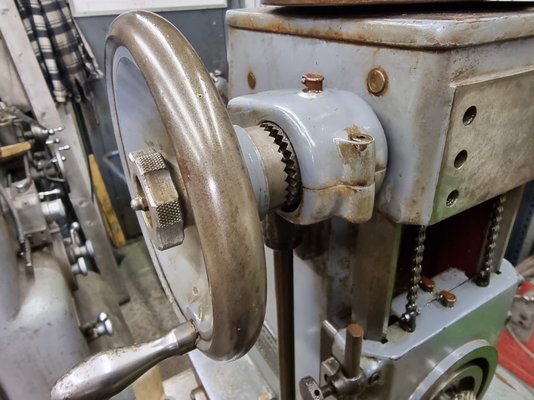

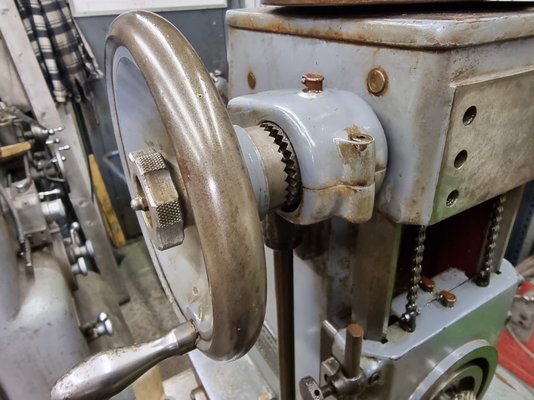

The downfeed handle slides in and out and is held out by a spring. It was all gummed up but now it's working just fine.

Down under the table there's an inspection cover. Behind it is a spring cover that closes an oiling hole which you fill with oil for the worm drive. I woner if anyone had bothered to ever fill it up but I have done it now.

Finally I measured the collet, to try to determine the type. Well, it's typical b@stard size British - 19/32" - 20tpi, which is exceeedingly close to 15mm - 1.25mm pitch.

That's about it for now I am confident that it's lubed up well enough to actually go into use.

Here's the revolving table, the bit that holds and turns the collet block for the gear blank arbor

Here's the drive gear and the bronze driven gear for the spindle. No wear to see.

The downfeed handle slides in and out and is held out by a spring. It was all gummed up but now it's working just fine.

Down under the table there's an inspection cover. Behind it is a spring cover that closes an oiling hole which you fill with oil for the worm drive. I woner if anyone had bothered to ever fill it up but I have done it now.

Finally I measured the collet, to try to determine the type. Well, it's typical b@stard size British - 19/32" - 20tpi, which is exceeedingly close to 15mm - 1.25mm pitch.

That's about it for now I am confident that it's lubed up well enough to actually go into use.

Last edited by a moderator:

Johnnybravo

Member

- Messages

- 3,690

- Location

- Northiam

There is a video on YouTube with a guy that builds a gearhobber that uses that differential gear arrangement. Might be worth watching to get a better idea of the principle behind it

Pete.

Member

- Messages

- 14,829

- Location

- Kent, UK

There is a video on YouTube with a guy that builds a gearhobber that uses that differential gear arrangement. Might be worth watching to get a better idea of the principle behind it

Johnny you the man, I found that video and in it is a perfect schematic of my machine's geartrain (and a description of how the differential works).

Martin Hocking

Member

- Messages

- 452

- Location

- Norfolk

So the helix is created by a gain or loss per rotation in the index feed?

Is there a link to the video? What is purpose of the differential?

Can’t the extra index feed be recreated by a slightly incorrect index train for the regular spur type?

Is there a link to the video? What is purpose of the differential?

Can’t the extra index feed be recreated by a slightly incorrect index train for the regular spur type?

paradipiro

Member

- Messages

- 105

- Location

- Budapest, Hungary

The differential adds an option to make bevel gears. If the differential is not in mesh, then the result is a helical gear. If the differential is engaged, (the table rotation is slowed down or speeded up refer to the reference, the helical gears teeth can be left or right angled. The differential's gearsets and resulting angles are in a big-big table in the manual.So the helix is created by a gain or loss per rotation in the index feed?

Is there a link to the video? What is purpose of the differential?

Can’t the extra index feed be recreated by a slightly incorrect index train for the regular spur type?

Johnnybravo

Member

- Messages

- 3,690

- Location

- Northiam

Look up YouTube user Toms Rabbit hole.So the helix is created by a gain or loss per rotation in the index feed?

Is there a link to the video? What is purpose of the differential?

Can’t the extra index feed be recreated by a slightly incorrect index train for the regular spur type?

paradipiro

Member

- Messages

- 105

- Location

- Budapest, Hungary

The teeth width is measured, then corrected by the depth of cut. First, you make a heavy cut around 75-80% of the final tooldepth, then measure the tooth width (W(k) in EU), then make a final pass accorduing to this dimension. I only know the metric measurements. Eg if the desired tooth width is off by 1mm or so, then you make a cut with this off-dimension with a correcting factor (~~1,43? I dont rememeber). The factor and all this method is mentioned in the manual. I only worked with a Lambert No. 68 hobber.does it also correct the bevel gear teeth for width? I can't begin to think how...

But the tooth width tapers along it's length? so it would need to be cut 3 times?The teeth width is measured, then corrected by the depth of cut. First, you make a heavy cut around 75-80% of the final tooldepth, then measure the tooth width (W(k) in EU), then make a final pass accorduing to this dimension. I only know the metric measurements. Eg if the desired tooth width is off by 1mm or so, then you make a cut with this off-dimension with a correcting factor (~~1,43? I dont rememeber). The factor and all this method is mentioned in the manual. I only worked with a Lambert No. 68 hobber.

Hmm, maybe bevel gears need a special machine, with shafts at adjustable angles, maybe shaper territory?The differential on mine only adds rotation to allow for helical gears helix angles. Nothing tondonwith bevels it can't cut them.

The theory for doing it in a mill with dividing head I can understand, but it would be easy to c*ck up...

paradipiro

Member

- Messages

- 105

- Location

- Budapest, Hungary

Yea.. it's not bevel gears, it's called helical gears.. I f*cked up with the correct word..The differential on mine only adds rotation to allow for helical gears helix angles. Nothing tondonwith bevels it can't cut them.

Martin Hocking

Member

- Messages

- 452

- Location

- Norfolk

Excellent recommendation mr bravo. I’ve just watched this video:Look up YouTube user Toms Rabbit hole.

Does a very good job of explaining a little of the maths behind it. I feel a bit more with it. Assuming anything he just said is actually correct!

I enjoyed this one to mr mutly. I am rather jealous of people who can communicate concisely.just pulled this up, not watched it all yet..

I still don’t quite understand whether it’s just not possible to calculate an index gear train with the correct ‘drift’ in its indexing so you have to have the differential or whether it’s simply the case that you’d need 100’s of different change gears to be of any practical use on a machine.

In any event mr pfauter gets a round of applause from me…

Johnnybravo

Member

- Messages

- 3,690

- Location

- Northiam

Glad to see you function at about the same pace I doNo workshop tonight. Instead I relaxed at my PC and took the time to edit the above image to show the geartrain better, to help visualise the functions. It's pretty cool and it only took me several hours.....

View attachment 424542