hotponyshoes

Member

- Messages

- 6,943

- Location

- Somerset. Uk

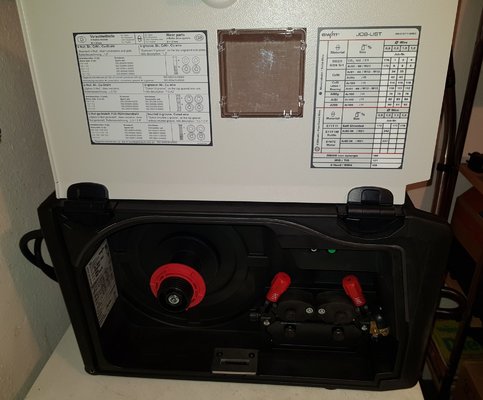

Had an early Friday finish today and it's nearly Christmas so I picked up a EWM Picomig 180 Puls.

I will do a bit of a write-up on why I went for this machine and some things I have found out when researching it.

If you just want to get into the actual review & pics then it will start a couple of posts down!

1st note if you are looking for info on these, is that EWM spell it Puls not Pulse and you will get more results on a google search if you look for both spellings!

Background:

I would class myself as a hobby welder, I am self employed and although I use welding a few times a month for my 'day' job the majority of the welding is done in the workshop in evenings or at the weekend. Tig, Mig and Stick, Anything from 0.5mm Saucepan Handles to 50mm digger bucket teeth.

My reasons for getting this machine are below and please bear in mind that my review is based against those reasons only. Also, I have never MIG welded alloy before so I would like to point out that this is my experience with how I get on with the first few uses.

Also, I will only really be reviewing my impressions of the machine, and its use on MIG welding alloy. I expect I will try steel and stainless MIG at some stage but I am not planing to use the Tig or Stick parts of it. If anybody wants me to try something let me know as it takes me a while to get round to it!

The official EWM promotional video:

says the machine is ideal for car work or hobby welders so I am expecting it to be fairly simple to set up and use and have good parts support and service available as required.

Personally, I think the price of this machine puts it outside of the hobby zone. There are a few functions (will go into later) that could justify this machine to the car repair industry. The main advantage I can see is that it is single phase. To be honest, If I had 3-phase power at the moment I would not even be looking at it but, as it is, I am working with what I have. I know there are plenty of other options at various other price points. I also know that a single-phase machine from a well regarded brand will sell easier and for more money than a no-name and I know it will be easy to part-ex it for a bigger machine with any welding dealer if I do get 3ph in the future.

If I do encounter problems with anything I will post it up and make it known just how easy or hard it is to sort out.

Although I do own and have used other welders and I have also compared various other machines before choosing this one I am only going to talk about this machine as it is or compared to a generic mig/tig welder rather than any direct comparisons against another branded machine to make sure I don't upset anybody by claiming my welder is better than yours because...

Also, The only prices I am going to use are the prices on the EMW web store as they stand today. I presume these are the official retail prices. Any I quote will be £GB Including vat. Any other discounted prices I quote will be online published prices from official UK dealers.

Please don't bother sending me pm's telling me I could have bought it for half the price from eastern Europe or from your mate who imports them directly..

So, Why did I want it?

There are a few items I make to order every now and again that I sell, These are the main justification for the purchase as I will make bit of the cost back with these.

I have been using an A/C Tig with pulse to weld up boxes from 2-3mm thick 5251 sheet. Normally the Tig takes me 3-4hrs or so to weld one up.

Clamping everything in place is a mission as I can't tack one-handed with the Tig. The welds also need to be cosmetically pleasing as well as functional. For this reason I would normally only attempt to weld one or 2 a day at a weekend. I am hoping that I can save an hour by being able to just hold the parts in place and tack it up quickly, then weld the whole thing in maybe another hour.

If I can do a couple in 2 evenings in the week and get a day back at the weekend I will consider this a good investment!!

I also get asked to do alloy welding odd jobs on a fairly regular basis. I expect currently I turn more than half of those down as I know they are going to take me hours to Tig and either I don't have the time or they would not want to pay me for the amount of time it would take.

I do have some potential automotive jobs for this machine that, if I can operate it correctly, would make a reasonable amount of return on it.

There are also plenty of things I would just like to make for myself which I might get round to if I can do them a bit quicker!

A lot of my projects have been made from steel when I would have preferred to use alloy, mainly because they are 1-offs, and the ability to hold them in place with one hand and give them a quick tack means it actually gets finished on the day I started!

So, to sum it up,

I want to be able to tack weld alloy with one hand & make pretty looking welds on 3mm sheet!

This should also be a substantial upgrade to my 15yr+ old transformer MIG (although that is a 280a machine so I wont be selling it just yet!

Like most of my tools, once I know what it and the operator are capable of I can find jobs for it afterwards!

I will do a bit of a write-up on why I went for this machine and some things I have found out when researching it.

If you just want to get into the actual review & pics then it will start a couple of posts down!

1st note if you are looking for info on these, is that EWM spell it Puls not Pulse and you will get more results on a google search if you look for both spellings!

Background:

I would class myself as a hobby welder, I am self employed and although I use welding a few times a month for my 'day' job the majority of the welding is done in the workshop in evenings or at the weekend. Tig, Mig and Stick, Anything from 0.5mm Saucepan Handles to 50mm digger bucket teeth.

My reasons for getting this machine are below and please bear in mind that my review is based against those reasons only. Also, I have never MIG welded alloy before so I would like to point out that this is my experience with how I get on with the first few uses.

Also, I will only really be reviewing my impressions of the machine, and its use on MIG welding alloy. I expect I will try steel and stainless MIG at some stage but I am not planing to use the Tig or Stick parts of it. If anybody wants me to try something let me know as it takes me a while to get round to it!

The official EWM promotional video:

says the machine is ideal for car work or hobby welders so I am expecting it to be fairly simple to set up and use and have good parts support and service available as required.

Personally, I think the price of this machine puts it outside of the hobby zone. There are a few functions (will go into later) that could justify this machine to the car repair industry. The main advantage I can see is that it is single phase. To be honest, If I had 3-phase power at the moment I would not even be looking at it but, as it is, I am working with what I have. I know there are plenty of other options at various other price points. I also know that a single-phase machine from a well regarded brand will sell easier and for more money than a no-name and I know it will be easy to part-ex it for a bigger machine with any welding dealer if I do get 3ph in the future.

If I do encounter problems with anything I will post it up and make it known just how easy or hard it is to sort out.

Although I do own and have used other welders and I have also compared various other machines before choosing this one I am only going to talk about this machine as it is or compared to a generic mig/tig welder rather than any direct comparisons against another branded machine to make sure I don't upset anybody by claiming my welder is better than yours because...

Also, The only prices I am going to use are the prices on the EMW web store as they stand today. I presume these are the official retail prices. Any I quote will be £GB Including vat. Any other discounted prices I quote will be online published prices from official UK dealers.

Please don't bother sending me pm's telling me I could have bought it for half the price from eastern Europe or from your mate who imports them directly..

So, Why did I want it?

There are a few items I make to order every now and again that I sell, These are the main justification for the purchase as I will make bit of the cost back with these.

I have been using an A/C Tig with pulse to weld up boxes from 2-3mm thick 5251 sheet. Normally the Tig takes me 3-4hrs or so to weld one up.

Clamping everything in place is a mission as I can't tack one-handed with the Tig. The welds also need to be cosmetically pleasing as well as functional. For this reason I would normally only attempt to weld one or 2 a day at a weekend. I am hoping that I can save an hour by being able to just hold the parts in place and tack it up quickly, then weld the whole thing in maybe another hour.

If I can do a couple in 2 evenings in the week and get a day back at the weekend I will consider this a good investment!!

I also get asked to do alloy welding odd jobs on a fairly regular basis. I expect currently I turn more than half of those down as I know they are going to take me hours to Tig and either I don't have the time or they would not want to pay me for the amount of time it would take.

I do have some potential automotive jobs for this machine that, if I can operate it correctly, would make a reasonable amount of return on it.

There are also plenty of things I would just like to make for myself which I might get round to if I can do them a bit quicker!

A lot of my projects have been made from steel when I would have preferred to use alloy, mainly because they are 1-offs, and the ability to hold them in place with one hand and give them a quick tack means it actually gets finished on the day I started!

So, to sum it up,

I want to be able to tack weld alloy with one hand & make pretty looking welds on 3mm sheet!

This should also be a substantial upgrade to my 15yr+ old transformer MIG (although that is a 280a machine so I wont be selling it just yet!

Like most of my tools, once I know what it and the operator are capable of I can find jobs for it afterwards!