- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Feeling a little restricted.

- Thread starter Richard.

- Start date

Richard.

Member

- Messages

- 18,335

- Location

- Cambridgeshire

Looking up live pipe centres today.

Wow they are dear things

Nearly everything I turn is Alu ATM and I'm doing pretty good with it but as soon as I want to skim the od on a pipe the fixed centre needs to come out etc etc.

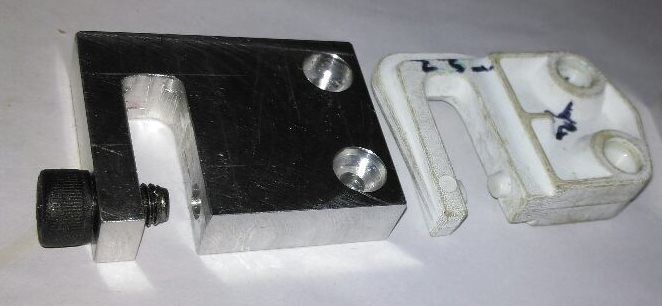

So I made a soft one to fit over my live centre. I went Alu for two reasons. 1) I had nothing else and 2 its soft so it won't mark my live centre with pressure applied.

After a few pipes it's gonna need a reface cos it will get marked up but hey no biggy. There is plenty of material on it.

It's good for up to 45mm I'd pipe.

Wow they are dear things

Nearly everything I turn is Alu ATM and I'm doing pretty good with it but as soon as I want to skim the od on a pipe the fixed centre needs to come out etc etc.

So I made a soft one to fit over my live centre. I went Alu for two reasons. 1) I had nothing else and 2 its soft so it won't mark my live centre with pressure applied.

After a few pipes it's gonna need a reface cos it will get marked up but hey no biggy. There is plenty of material on it.

It's good for up to 45mm I'd pipe.

Richard.

Member

- Messages

- 18,335

- Location

- Cambridgeshire

Before any one asks. The taper on the live centre nips up against a recess in the new centre head. The new head is live and doesn't make contact with the centre body. It's a snug fit down the 18mm shaft then nips up against the 13mm recess.

Works beautifully.

Works beautifully.

Richard.

Member

- Messages

- 18,335

- Location

- Cambridgeshire

That's what I noticed Pete. My saw is very good but it's still 0.2mm out of square on the vertical and the centre noticed it straight away. I faced off the short pipe unsupported and then refit it which then it ran bang on.That's a handy job Richard.

The only trouble with pipe centres comes if the pipe is not cut square, it makes it run out of true.

you might be able to use one of these as a pipe centre,

http://www.recordpower.co.uk/product/live-centre--2-morse-taper

Ive got a 1mt version and they are 33mm diameter (not sure if the 2mt version is bigger or not).

they are also relatively soft as you can mark them with a scriber.

http://www.recordpower.co.uk/product/live-centre--2-morse-taper

Ive got a 1mt version and they are 33mm diameter (not sure if the 2mt version is bigger or not).

they are also relatively soft as you can mark them with a scriber.

Pete.

Member

- Messages

- 15,075

- Location

- Kent, UK

That's what I noticed Pete. My saw is very good but it's still 0.2mm out of square on the vertical and the centre noticed it straight away. I faced off the short pipe unsupported and then refit it which then it ran bang on.

I've made sacrificial ends before that plug into the tube and were drilled for a centre, which you can use to part tube off to length. You part it most of the way through then tear off the rest like a ring-pull (if you get it right). If you made one of these that fitted over your revolving centre like your current one you could part right through the work because the sacrificial plug would be supported.

Bit like an internal fixed steady.

gaz1

Member

- Messages

- 20,546

- Location

- westyorkshire

I've picked it up.

It's a little ml10.

I have put it together this evening and started turning things.

Well I must say for a little lathe it's a very good accurate tool. I turned down, faced off and internally bored out some short sections of pipe to practice with and really enjoyed it.

I paid £600 for it with just about every possible addition you can imagine so I'll have no prob getting that back. Its the newer metric version too which I like.

I'll want a bigger one I'm sure in 3-6 months when I'm more acute with it. For its size it's a really usable thing (for me).

It's even got a milling slide with vice (doubt it's gonna get used) both steadys, Pratt 3/4 jaws, live centres , jaCubs drill, 2 post quick release tool post. And loads more. I had a car full of stuff. Solid thing without a fraction of play.

Motor clicks mind so I'm gonna check the fan on the shaft Tomoz see if it needs tightening.

All in all it's great for practice and turning things less than a foot long.

well its over a year now for this have you decided to stick with what you have or have you decided to change and upgrade your machine to another

though thread has gone really quiet so what have you made recently using it ?

Richard.

Member

- Messages

- 18,335

- Location

- Cambridgeshire

You know what mate there has been loads of times when I've thought "yeah time for a Bantum" but I've never actually taken it any further than that. I could now fit a bigger one in too after a recent move around. Tbf it's used more frequently than I imagined but the capacity I'm using it for has always been on such a small scale. I use the V slide a lot too for small slots and key ways it's great. There is really no need to go bigger. Yes I would love it and I'm sure I'd use it more but I'm turning small bespoke Alu fittings mostly. Done a few bearing collars, spacers, pins , it's all small work. Accuracy is what I need not size. It does that very well and I take very good care of it.well its over a year now for this have you decided to stick with what you have or have you decided to change and upgrade your machine to another

though thread has gone really quiet so what have you made recently using it ?

Got a few like that Richard for different diameters, some a few years ago others 15 yrs or more ago. Need only to fit over the protruding live centre cock on should feel an air lock.

Problem will have using a too large for the job is start point on cutter needing a recess in the aluminium cone. Never bothered to recut as cant hold square.

Problem will have using a too large for the job is start point on cutter needing a recess in the aluminium cone. Never bothered to recut as cant hold square.

Richard.

Member

- Messages

- 18,335

- Location

- Cambridgeshire

Little update on this thread.

I’ve been making some parts for a trike headstock. I’ve made loads on this little lathe but I’m putting these ones up because I found these to be particularly challenging simply because they were bigger than probably what the little lathe was designed for.

My steady was no use for these and as the difficult task required boring out the tube to bearing fit tolerance I wasn’t able to hold between centres. It was a case of clocking that bend, seam welded nasty pipe in the 4 jaw and slowly cutting them out. Made the end caps with discs and welded them on the tubes. Then turned them down. A 290mm pin was made and threaded both ends m20 x 2.5. I’ve got a fuel tank to build for it next. That will be mostly fabrication but a few fittings and filler cap will be sorted on the ml10. I cocked a couple of these up by slightly over boring them and had to do it again. I read loads of posts on other forums saying how incapable of work these tiny ml10’s are.... I don’t really understand how they are. You’ve just got to work with it. It will produce the goods if you think about it and are prepared to go a little slower and steadier. Pics coming up when I find them.

I’ve been making some parts for a trike headstock. I’ve made loads on this little lathe but I’m putting these ones up because I found these to be particularly challenging simply because they were bigger than probably what the little lathe was designed for.

My steady was no use for these and as the difficult task required boring out the tube to bearing fit tolerance I wasn’t able to hold between centres. It was a case of clocking that bend, seam welded nasty pipe in the 4 jaw and slowly cutting them out. Made the end caps with discs and welded them on the tubes. Then turned them down. A 290mm pin was made and threaded both ends m20 x 2.5. I’ve got a fuel tank to build for it next. That will be mostly fabrication but a few fittings and filler cap will be sorted on the ml10. I cocked a couple of these up by slightly over boring them and had to do it again. I read loads of posts on other forums saying how incapable of work these tiny ml10’s are.... I don’t really understand how they are. You’ve just got to work with it. It will produce the goods if you think about it and are prepared to go a little slower and steadier. Pics coming up when I find them.

Richard.

Member

- Messages

- 18,335

- Location

- Cambridgeshire

That long tube was 60x200. A lot of unsupported length there getting bored out each end. It was a back gears job and very light cuts after it took me 20 mins to clock the unsupported end true.

-

37E98FA5-F220-464E-A1A9-198F454C533F.jpeg304.6 KB · Views: 104

37E98FA5-F220-464E-A1A9-198F454C533F.jpeg304.6 KB · Views: 104 -

5D56B7E7-7B1B-4EDA-BAE0-33BB963530B2.jpeg274.6 KB · Views: 102

5D56B7E7-7B1B-4EDA-BAE0-33BB963530B2.jpeg274.6 KB · Views: 102 -

B99DE65C-21B6-45C1-8693-F6E254392D71.jpeg266.1 KB · Views: 102

B99DE65C-21B6-45C1-8693-F6E254392D71.jpeg266.1 KB · Views: 102 -

E5BF162A-B3C5-4A62-886D-2E7D56AAE855.jpeg225.2 KB · Views: 110

E5BF162A-B3C5-4A62-886D-2E7D56AAE855.jpeg225.2 KB · Views: 110 -

AFD9E4DE-8E5C-410E-82AC-F8C4B5E00088.jpeg226.4 KB · Views: 106

AFD9E4DE-8E5C-410E-82AC-F8C4B5E00088.jpeg226.4 KB · Views: 106 -

D50E1EDF-9B2E-4B82-8F53-3FC829C22B6F.jpeg153.5 KB · Views: 97

D50E1EDF-9B2E-4B82-8F53-3FC829C22B6F.jpeg153.5 KB · Views: 97

addjunkie

Member

- Messages

- 14,338

- Location

- Northumberland. Reet oot in the sticks

Why was your steady no use, thats the weapon of choice for headstocks. Looks like a nice finish once the hurdles have been overcome.

Normally a steering stem has an additional thread for tightening up against the top of the upper bearing, before the top yoke goes on.

Milling the yokes to match on the ml10 will keep you occupied next weekend.

Normally a steering stem has an additional thread for tightening up against the top of the upper bearing, before the top yoke goes on.

Milling the yokes to match on the ml10 will keep you occupied next weekend.

Richard.

Member

- Messages

- 18,335

- Location

- Cambridgeshire

60mm diameter

My steady won’t support work that big.

The steering column is the longest tube with the bearings. The pin goes through and two of those cups bolted either end. The other two smaller tubes with bearings are for the suspension and the other two cups for the front hub. It’s a very tried and tested design. He’s simply copying one that was built a while ago. I just did some turning for him.

My steady won’t support work that big.

The steering column is the longest tube with the bearings. The pin goes through and two of those cups bolted either end. The other two smaller tubes with bearings are for the suspension and the other two cups for the front hub. It’s a very tried and tested design. He’s simply copying one that was built a while ago. I just did some turning for him.

Richard.

Member

- Messages

- 18,335

- Location

- Cambridgeshire

addjunkie

Member

- Messages

- 14,338

- Location

- Northumberland. Reet oot in the sticks

Yes then leading link.This is the front fork assembly that he intends to copy. He is building a complete trike eventually. I’m doing the bits he can’t do. Like the machining and the aluminium welding.

Richard.

Member

- Messages

- 18,335

- Location

- Cambridgeshire

It’s gonna be the 2nd one he’s built. It’s got a 2.0L pinto lump to go into it so it’s gonna be pokeyYes then leading link.

Bill Edwards

Member

- Messages

- 4,956

- Location

- Scarborough, North Yorkshire

Nice looking work. Must certainly be satisfying for you, doing the job with such limitations.

My next lathe will easily take that sized job through the chuck (and almost through the spindle) without even bothering with a steady - but that's easy with no skill required. Working beyond the practical capabilities of a machine will teach you a lot more.

And of course, no matter how big the lathe it's always possible to encounter a job that's pushing it's size capability, but it'll happen less often.

My next lathe will easily take that sized job through the chuck (and almost through the spindle) without even bothering with a steady - but that's easy with no skill required. Working beyond the practical capabilities of a machine will teach you a lot more.

And of course, no matter how big the lathe it's always possible to encounter a job that's pushing it's size capability, but it'll happen less often.

eLuSiVeMiTe

Member

- Messages

- 16,438

- Location

- ......

Tidy work.

Time to make a new steady.

Time to make a new steady.