You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gas welding aluminium

- Thread starter lotus 30

- Start date

they were sweet , like a Bonnie tank shape with manx norton knee dents ,, and a sachs engine , oh they really were sweet.Mate of mine used to gas weld fuel tanks for Dalesman motorcycles, very, very neat. Try as hard as I could I never mastered it

lotus 30

classic car enthusiast mostly lotus

- Messages

- 712

- Location

- caldicot south wales uk

Well i have spent some hours on this welding is very inconsistent some times it ok others its religious very holly lol but i shall paint the car so some filler will be the order of the day. I find fluxing both sides of the eld is better and open the bottle regulators a bit more than i need and adjust flame on the lamp. I also find i need a little more heat to start a weld and turn down as i go otherwise the weld will not start got a good grinder so i am getting there. It maks no difference new ali to old lo it ether goes well or disaster very critical an flame very low pressure.

Andy

Andy

Dell

Member

- Messages

- 212

- Location

- Warwickshire

Hi Andy

I have just seen your post because until yesterday I hadn’t been on forum for a while, I have been gas welding aluminium for about 50 years on and of .

When I weld new to old I use a strip and clean wheel on the old on both sides if possible to try and get as much contamination out as possible, I cut narrow strips of what ever I am welding ( I never use rods ), a lot of people advocate fluxing work but all I do is dip aluminium strip in flux powder ( but not in the pot as it’s hygroscopic) tip some in another container and never put back, bias the torch towards the new material unless it is small as it takes longer to heat than the old, wash flux off with boiling water ( BUT DO NOT BREATH VAPOUR ) as it is corrosive.

Hope this helps Dell

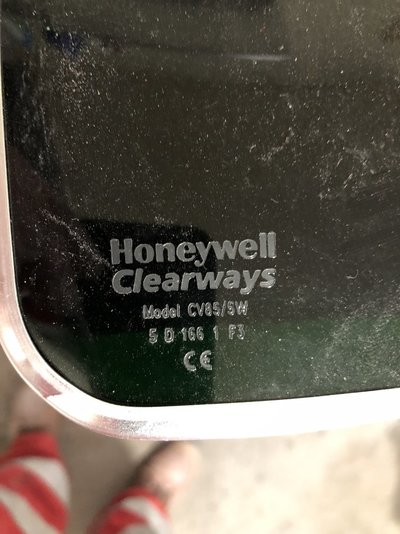

PS I will try not to forget to look at visor

I have just seen your post because until yesterday I hadn’t been on forum for a while, I have been gas welding aluminium for about 50 years on and of .

When I weld new to old I use a strip and clean wheel on the old on both sides if possible to try and get as much contamination out as possible, I cut narrow strips of what ever I am welding ( I never use rods ), a lot of people advocate fluxing work but all I do is dip aluminium strip in flux powder ( but not in the pot as it’s hygroscopic) tip some in another container and never put back, bias the torch towards the new material unless it is small as it takes longer to heat than the old, wash flux off with boiling water ( BUT DO NOT BREATH VAPOUR ) as it is corrosive.

Hope this helps Dell

PS I will try not to forget to look at visor

lotus 30

classic car enthusiast mostly lotus

- Messages

- 712

- Location

- caldicot south wales uk

Dell thanks i am not doing bad my welds are withstanding hammering some are a little bloby lol when the old ali runs away from me i have learnt an awful lot and turned the gas pressure down to a min. The hardest bit is starting the weld once i start the run its ok as long as i keep an eye on the heat as with all welding i suppose this morning i had to weld some 16 gauge new ali a walk in the park compared to the old 20 gauge and quite neat. I do love a challengeHi Andy

I have just seen your post because until yesterday I hadn’t been on forum for a while, I have been gas welding aluminium for about 50 years on and of .

When I weld new to old I use a strip and clean wheel on the old on both sides if possible to try and get as much contamination out as possible, I cut narrow strips of what ever I am welding ( I never use rods ), a lot of people advocate fluxing work but all I do is dip aluminium strip in flux powder ( but not in the pot as it’s hygroscopic) tip some in another container and never put back, bias the torch towards the new material unless it is small as it takes longer to heat than the old, wash flux off with boiling water ( BUT DO NOT BREATH VAPOUR ) as it is corrosive.

Hope this helps Dell

PS I will try not to forget to look at visor

lotus 30

classic car enthusiast mostly lotus

- Messages

- 712

- Location

- caldicot south wales uk

yep got one as advised by you works well