Dr.Al

Forum Supporter

- Messages

- 2,459

- Location

- Gloucestershire, UK

Thanks for all the replies; I'll try to spend a bit of time on it tonight.

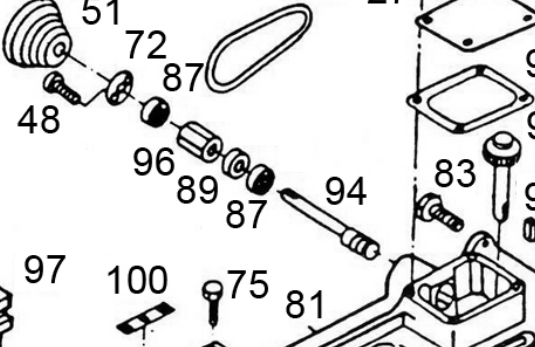

Yes, I'm pretty sure this is the function of the retaining plate as I said earlier - item 72 in this drawing (item 94 is the shaft with the worm on the end):

The forces on the worm shaft from cutting will be trying to push the worm shaft out of the gear box, i.e. pushing on the retaining plate.

I haven't tried pushing it in, but it might be worth a punt. It doesn't look like there's a lip on the inside, but I can't be absolutely sure. I'll get some more photos from different angles this evening.

I've got some ER collets and collet blocks, so I might try gripping the shaft with one of those (they hold all the way round, are very firm and shouldn't damage the shaft). That might give me something to work with.

Drilling a hole for a drift was one thing I'd considered, but I prefer your suggestion of the plate with a thread in it. I'm still going to leave this as a last resort as I'd rather not drill the hole, but thanks anyway.

I'll take some more photos tonight. I'm pretty sure the bearings are 6202 size: 15 × 35 × 11 mm. The reason I mention this is that there's only a 6.1 mm gap from the end of the worm shaft and the boss on the casting, so I won't be able to drive it in far enough to get full access to the bearing to cut it.

Pulling or pushing still needs to be held

Yes, I'm pretty sure this is the function of the retaining plate as I said earlier - item 72 in this drawing (item 94 is the shaft with the worm on the end):

The forces on the worm shaft from cutting will be trying to push the worm shaft out of the gear box, i.e. pushing on the retaining plate.

Not necessarily.

As it's a bandsaw, it should only ever run the one way, so it could simply be relying on the force pulling everything against a boss.

@Dr.Al have you tried pressing the worm in, to see if it at least moves through the bearings?

If you've got somebody else to help steady things, another thing to try would be grip the shaft in a vise, then hit the housing.

I haven't tried pushing it in, but it might be worth a punt. It doesn't look like there's a lip on the inside, but I can't be absolutely sure. I'll get some more photos from different angles this evening.

I've got some ER collets and collet blocks, so I might try gripping the shaft with one of those (they hold all the way round, are very firm and shouldn't damage the shaft). That might give me something to work with.

Id cheat, drill a hole in the casting, inline with the shaft (itd remove the boss -so measure shaft to casting for reassembly). Peice of plate to fit in the gap with a m10 or m12 fine thread, screw a bolt from outside and you have a pusher. After, tap casting bigger and fit a plug.

Drilling a hole for a drift was one thing I'd considered, but I prefer your suggestion of the plate with a thread in it. I'm still going to leave this as a last resort as I'd rather not drill the hole, but thanks anyway.

got any more photos?

I'd knock it in first.... cut the inner bearing off with a grinder and then push it out... once the outside bearing is out it should pop right out?

I'll take some more photos tonight. I'm pretty sure the bearings are 6202 size: 15 × 35 × 11 mm. The reason I mention this is that there's only a 6.1 mm gap from the end of the worm shaft and the boss on the casting, so I won't be able to drive it in far enough to get full access to the bearing to cut it.