- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Home Made Tools and Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

homemade lathe, that actually make things

- Thread starter gavcarter

- Start date

gavcarter

Member

- Messages

- 458

- Location

- Hartlepool

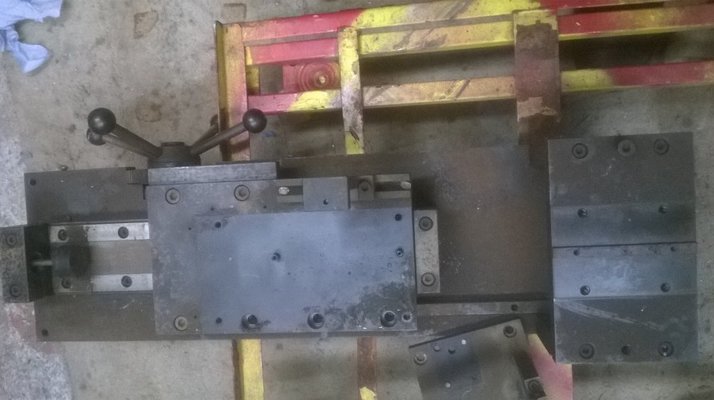

that does look good and heavy, im guessing it gets about 6" of travel?

THK linear rails are supposed to be top notch.

here are some suggestions for your build, not intended to put you off, just things to keep in mind, took me a few attempts to get something that worked properly and believe me, a metal lathe sees forces well into the 100's of kg when cutting. I know its easy to say oh well ill just do little cuts, but you will be soon sick of it when you are working with it

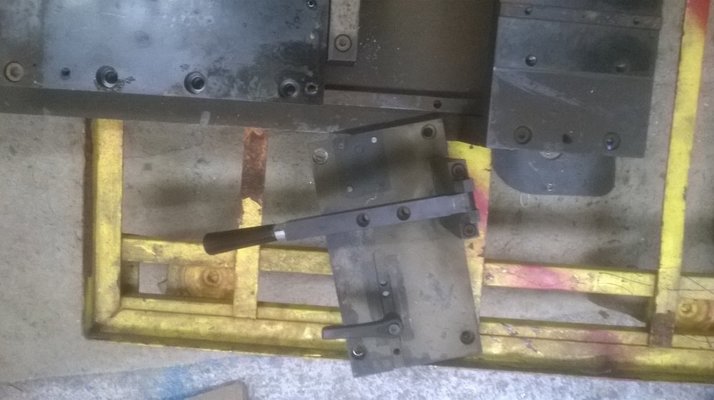

the big pinion gear looks like it will be a bit big for fine work, I would definitely consider adding a smaller one for fine feeding, it will give more control, especially when doing finishing cuts or working close to the chuck. Then again it might be ok if its all your used to,however I don't see anyway to hold the carriage in place yet, is this something your adding?

the way the pinion and rack are set up, the lathe will just push against the carriage and turn the handle for you, sending the carriage back to the bottom of the bed, unless you stand and hold it, no good for facing off etc as you will need two hands to operate the lathe.

it seems easy adding a locking bolt to push on the bed, this will try and lift the carriage off the rails locking it in place, only problem is the rails are not designed to take an upwards load.

A good fitting worm gear would be a better solution, as it would self lock, and also give a much finer feed, negating the need to make another left/right feed on top of your carriage, unless you want to of course.

the carriage looks very wide. If you can centre your cutting tool ( not the tool post) on the first bearing block, I don't think you will need the second one. This will do two things. It will either allow an extra few inches of travel OR it would free up a bearing block for a tailstock, this is your choice...

the forces a lathe sees are mainly twisting forces. The carriage way will spend a lot more time being twisted front to back ( looking from user point of view) than it will left to right. As I said earlier getting the cutting tool centred above the bearing slide ( left to right) will take most of the force and apply it downwards onto the rails. That part standing up is about bang on for the centre of your cutting tools, too far left it will try to tip the carriage way up towards the headstock.

you need to consider the sizes of stock you will be working on too. You can extend the carriage way out towards the user as far as you like to get big diameter stock in there BUT the further you do this the more leverage is placed on the rails. If the tip of your cutting tool is closer to you than the edge of the bearing rail, when looking dead on from above, then the cutting forces are going to try to twist and bend that rail towards you and rip it off the bed/ smash the bearing block. Keep things central and this should be reduced, the rail will see downwards pressure rather than twisting actions, which is what it was designed for. Obviously those types of slides can cope with some side to side pressures, or diagonal forces, but they take downwards pressure a LOT better.

THK linear rails are supposed to be top notch.

here are some suggestions for your build, not intended to put you off, just things to keep in mind, took me a few attempts to get something that worked properly and believe me, a metal lathe sees forces well into the 100's of kg when cutting. I know its easy to say oh well ill just do little cuts, but you will be soon sick of it when you are working with it

the big pinion gear looks like it will be a bit big for fine work, I would definitely consider adding a smaller one for fine feeding, it will give more control, especially when doing finishing cuts or working close to the chuck. Then again it might be ok if its all your used to,however I don't see anyway to hold the carriage in place yet, is this something your adding?

the way the pinion and rack are set up, the lathe will just push against the carriage and turn the handle for you, sending the carriage back to the bottom of the bed, unless you stand and hold it, no good for facing off etc as you will need two hands to operate the lathe.

it seems easy adding a locking bolt to push on the bed, this will try and lift the carriage off the rails locking it in place, only problem is the rails are not designed to take an upwards load.

A good fitting worm gear would be a better solution, as it would self lock, and also give a much finer feed, negating the need to make another left/right feed on top of your carriage, unless you want to of course.

the carriage looks very wide. If you can centre your cutting tool ( not the tool post) on the first bearing block, I don't think you will need the second one. This will do two things. It will either allow an extra few inches of travel OR it would free up a bearing block for a tailstock, this is your choice...

the forces a lathe sees are mainly twisting forces. The carriage way will spend a lot more time being twisted front to back ( looking from user point of view) than it will left to right. As I said earlier getting the cutting tool centred above the bearing slide ( left to right) will take most of the force and apply it downwards onto the rails. That part standing up is about bang on for the centre of your cutting tools, too far left it will try to tip the carriage way up towards the headstock.

you need to consider the sizes of stock you will be working on too. You can extend the carriage way out towards the user as far as you like to get big diameter stock in there BUT the further you do this the more leverage is placed on the rails. If the tip of your cutting tool is closer to you than the edge of the bearing rail, when looking dead on from above, then the cutting forces are going to try to twist and bend that rail towards you and rip it off the bed/ smash the bearing block. Keep things central and this should be reduced, the rail will see downwards pressure rather than twisting actions, which is what it was designed for. Obviously those types of slides can cope with some side to side pressures, or diagonal forces, but they take downwards pressure a LOT better.

gavcarter

Member

- Messages

- 458

- Location

- Hartlepool

remember you well from the chinese airgun forum

polecat

that would be the one! It's moved now, no idea where to though