You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to make a tight bend in 1" steel tubing? Pictures inside

- Thread starter Tombodge

- Start date

Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,559

- Location

- Norwich, Norfolk, UK

Looking at that photo of the die and by my reckoning I make it to be a Centre Line Radius of 4".

Looking at the photo of the bent material, that is an awful lot of waisting in the bend, and again by my reckoning you are looking at a good 15% and maybe even 20% reduction in the tube's diametre.

Looking at the photo of the bent material, that is an awful lot of waisting in the bend, and again by my reckoning you are looking at a good 15% and maybe even 20% reduction in the tube's diametre.

Kent

Member

- Messages

- 9,988

- Location

- Bowland, Lanacshire,UK

Alright mate. Im from sutton coldfield but im spending a fair amount of time in telford aswell

Bit far. Often it's worth a mention because folk local to you can often be ok with letting you use their kit on one off jobs like this

Looking at that photo of the die and by my reckoning I make it to be a Centre Line Radius of 4".

Looking at the photo of the bent material, that is an awful lot of waisting in the bend, and again by my reckoning you are looking at a good 15% and maybe even 20% reduction in the tube's diametre.

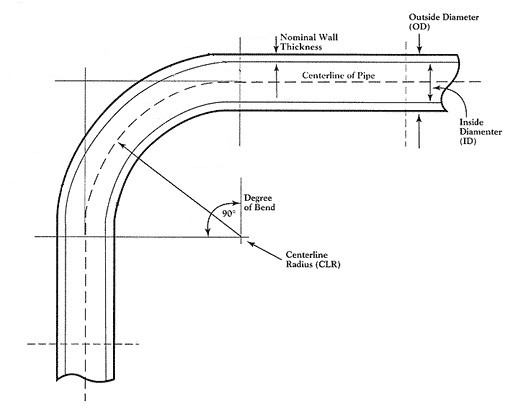

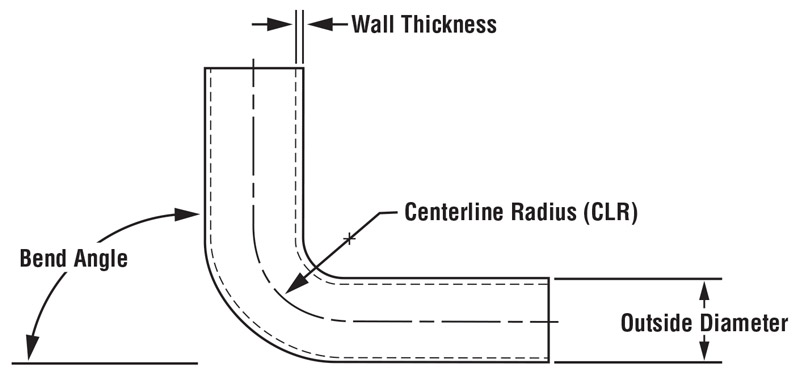

I think that might be the photo to be honest. It looks alright in the flesh. How do you measure the CLR. Is that from the middle of the die to the midle of the tube? Ive remeasured and if thats the case your stop on. Its a 4".

Wheres the cheapest place for me to get a 3" CLR 1" tube bender from? Theres some on ebay but it doesnt state the center line raduis

https://www.ebay.co.uk/ulk/itm/141914238422

I was looking at this. Bare in mind that it will only be for the odd job. But im unsure what the CLR for the 1 inch is

I was looking at this. Bare in mind that it will only be for the odd job. But im unsure what the CLR for the 1 inch is

Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,559

- Location

- Norwich, Norfolk, UK

OK, the tube bending kit at that ebay link is identical to the Baileigh RDB 25 kit and there are several other distributors selling the exact same kit but under their brand names, logos & colours. My advice is don't even bother with it!

I originally went to Bailegh because of their reputation and was sorely let down.......... I shall never go back to them again for any product.

Somewhere about the place I have a USB stick with a video of me using the Baileigh RBD 25 bender and ruining lots bits of tube of all diameters.... I did not make one decent bend with that kit! ......... I'll try and remember to dig out the video and post it up on here this weekend.

The following illustrations I have pulled from the Internet should help to explain CLR to you.

I originally went to Bailegh because of their reputation and was sorely let down.......... I shall never go back to them again for any product.

Somewhere about the place I have a USB stick with a video of me using the Baileigh RBD 25 bender and ruining lots bits of tube of all diameters.... I did not make one decent bend with that kit! ......... I'll try and remember to dig out the video and post it up on here this weekend.

The following illustrations I have pulled from the Internet should help to explain CLR to you.

tinman123

Putting the Extra into ordinary.

- Messages

- 1,068

- Location

- Northern Iron.

the jd2 m3 look a fine bender.Not with the JD2, the waisting on the bend of 16 gauge is around 1% of tube diameter.... but that is why good quality dies & followers are not cheap.

she draws the pipe through it when bending dosent it, which would save the pipe and allow for tighter bends.

did the baileigh work the same way or more like a conventional pipe bender where the form moves against the guides.

tubela stuff i know and have used, its good gear.

by the way, Camel saddles you say,

for actual camels or am i missing something here.

Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,559

- Location

- Norwich, Norfolk, UK

The JD2 M3 is a draw bender drawing the tube around and into the die, and the Bailiegh is a push bender, pushing or more accurately rolling the tube into the well of the die.

Yes, Camel Saddles, I make the steel frames for Camel saddles, both Bactrian and Dromedary Camels. I also make the steel frames for Mule & Pony pack frames, Llama pack frames and Elephant howdahs.

I export the Dromedary Camel saddle frames to Western Sahara, across most of North Africa and the Levant, the Middle East and Australia, the Dromedary Camels saddle frames go to Mongolia, China, Siberia and Northern India. The Mule Pack frames go to Canada, USA, South Africa, Namibia and Zimbabwe (via SA). The Llama pack frames go to South America the USA and across the UK. The Elephant Howdah frames go to India, Vietnam, Thailand, Laos and Cambodia.

A finished two person seater or one person and packs Dromedary Camel saddle frame ready to go to the powder coaters prior to going to the leather workers for finishing.

The Slide Show

Yes, Camel Saddles, I make the steel frames for Camel saddles, both Bactrian and Dromedary Camels. I also make the steel frames for Mule & Pony pack frames, Llama pack frames and Elephant howdahs.

I export the Dromedary Camel saddle frames to Western Sahara, across most of North Africa and the Levant, the Middle East and Australia, the Dromedary Camels saddle frames go to Mongolia, China, Siberia and Northern India. The Mule Pack frames go to Canada, USA, South Africa, Namibia and Zimbabwe (via SA). The Llama pack frames go to South America the USA and across the UK. The Elephant Howdah frames go to India, Vietnam, Thailand, Laos and Cambodia.

A finished two person seater or one person and packs Dromedary Camel saddle frame ready to go to the powder coaters prior to going to the leather workers for finishing.

The Slide Show

tinman123

Putting the Extra into ordinary.

- Messages

- 1,068

- Location

- Northern Iron.

as they say, you learn a new thing every day.

tidy work there even tho most of it will never be seen id say.

ive had a spin on a camel but i never thought about how the seat i was on was made, or that there was someone who sounds right busy making them, in the uk none the less, thats mad.

cool.

tidy work there even tho most of it will never be seen id say.

ive had a spin on a camel but i never thought about how the seat i was on was made, or that there was someone who sounds right busy making them, in the uk none the less, thats mad.

cool.

Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,559

- Location

- Norwich, Norfolk, UK

As promised a link to the thread about the tube/pipe bending kit I have put up in the Tools, Materials & Techniques section: www.mig-welding.co.uk/forum/threads/generic-tube-pipe-bending-kits.62712/

Jim Davey

R H Davey Welding Supplies Ltd

- Messages

- 5,736

- Location

- Southampton

Very tidy work on the seat frames......the mind boggles as to how one finds work from such a diverse client base

Straight from the Camels mouth.

Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,559

- Location

- Norwich, Norfolk, UK

So do you have jigs/templates/fixtures which give a close match to each breed, or is each one a bespoke measure and make?

That is confidential information.

MattF

Forum Supporter

- Messages

- 17,595

- Location

- South Yorkshire

That is confidential information.

Regardless, that looks like some nice work you do there.

Regardless, that looks like some nice work you do there.

tinman123

Putting the Extra into ordinary.

- Messages

- 1,068

- Location

- Northern Iron.

how did you get into it in the first place if you dont mine me asking, and not being nosy or anything, or wanting to start into it, just amazes me times how folk end up doing certain things that are off the beaten track so to speak.The JD2 M3 is a draw bender drawing the tube around and into the die, and the Bailiegh is a push bender, pushing or more accurately rolling the tube into the well of the die.

Yes, Camel Saddles, I make the steel frames for Camel saddles, both Bactrian and Dromedary Camels. I also make the steel frames for Mule & Pony pack frames, Llama pack frames and Elephant howdahs.

I export the Dromedary Camel saddle frames to Western Sahara, across most of North Africa and the Levant, the Middle East and Australia, the Dromedary Camels saddle frames go to Mongolia, China, Siberia and Northern India. The Mule Pack frames go to Canada, USA, South Africa, Namibia and Zimbabwe (via SA). The Llama pack frames go to South America the USA and across the UK. The Elephant Howdah frames go to India, Vietnam, Thailand, Laos and Cambodia.

A finished two person seater or one person and packs Dromedary Camel saddle frame ready to go to the powder coaters prior to going to the leather workers for finishing.

theres always a story.

do you do bicycles too?.

Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,559

- Location

- Norwich, Norfolk, UK

It all originally stemmed from a travel company that specialised in gap year expeditions for students. A student was severely injured whilst on a Camel trekking holiday in Egypt when a very old and locally made steel camel saddle frame broke at a dodgy welded joint. The sharp steel broken weld edge slashed into the student's thigh and almost severed their femoral artery from which they could have bled to death. The travel company got sued, so they vowed to only have insurance company approved equipment on their expeditions in the future. A set of specs were recommend, but more importantly I had done some work a few weeks before for the Engineering design company who set the specs. The job was too small for the usual Engineering & Fabrication contractor (who would have subbed it to me anyway), and the expedition company did not want to pay for the development to final product stages. I had worked for Sanderson, Claas and Caterpillar as an R&D engineer in the dim & distant and knew most if not all the pitfalls and some of the traps, so I bit the bullet and put an all intellectual rights retained and exclusive right to market worldwide contract in place and then developed the products at my expense. They saw the cost savings involved, and I got the contract for several expedition locations in Africa and then a few months later we exercised the same arrangement for Elephant trekking expedition howdahs for India and Thailand. With all the intellectual and marketing rights retained as mine, the products then got picked up on the Internet and other trekking and expedition companies made enquiries and placed orders.

I rarely make my in house designed two wheel cargo bicycles these days, this market sector in Europe is being killed by cheap imports from China, but I concentrate on bespoke made to order utility tricycles and electric assist pedal powered quads as light weight transport for factory, utility and municipal sites: capacity of one person and up to 250kg payload. I have also made 6 electric assist pedal powered cultivation tool carriers for a major glasshouse grower located both here in East Anglia and the Netherlands. This is a sort of on going development project, which is very interesting due to my agricultural engineering roots, my love of bicycles and passion for the bizarre and unusual, and again I have secured all of the future rights. I am also working on and off on an "in doors" electric assist pedal powered utility vehicle for use in large office blocks, shopping complexes and other public buildings to move stock, consumables and office furniture but this has turned out to be a not so easy a project due the proximity of other people and the general public moving about in the working environment.

I rarely make my in house designed two wheel cargo bicycles these days, this market sector in Europe is being killed by cheap imports from China, but I concentrate on bespoke made to order utility tricycles and electric assist pedal powered quads as light weight transport for factory, utility and municipal sites: capacity of one person and up to 250kg payload. I have also made 6 electric assist pedal powered cultivation tool carriers for a major glasshouse grower located both here in East Anglia and the Netherlands. This is a sort of on going development project, which is very interesting due to my agricultural engineering roots, my love of bicycles and passion for the bizarre and unusual, and again I have secured all of the future rights. I am also working on and off on an "in doors" electric assist pedal powered utility vehicle for use in large office blocks, shopping complexes and other public buildings to move stock, consumables and office furniture but this has turned out to be a not so easy a project due the proximity of other people and the general public moving about in the working environment.

We/I seem to have hijacked the original thread and discussion,

so I am not going to comment about me and what I do any more.

That can go into another thread in the relevant forum section.

I will however continue to discuss the CLR of tubes in this thread.

so I am not going to comment about me and what I do any more.

That can go into another thread in the relevant forum section.

I will however continue to discuss the CLR of tubes in this thread.

Last edited: