You sure? Looks like 4 screws to me, two in the T slot on the left (facing the lathe as if you're using it), two on the right.Sorry - I may be getting terminology wrong, but the whole lump (apron and saddle?) appears to be a single cast unit

- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I've broken my lathe

- Thread starter skotl

- Start date

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,351

- Location

- NE London - UK

The carriage is the whole lump. Comprising the saddle and the apron.the whole lump (apron and saddle?

RobCox

Member

- Messages

- 444

- Location

- Cambridge, UK

Have a look at vintagemachinery.org. There are several Colchester manuals available there for (free) download. None will prob be your machine but it might give a clue as to how to separate the apron from the cross slide. As @Fastdruid has suggested, four screws, 2 each side, makes sense.

Undo these 4 and the apron should separate from the saddle. Beware that if you do it without supporting the apron you will likely bend the powerfeed shaft and leadscrew.

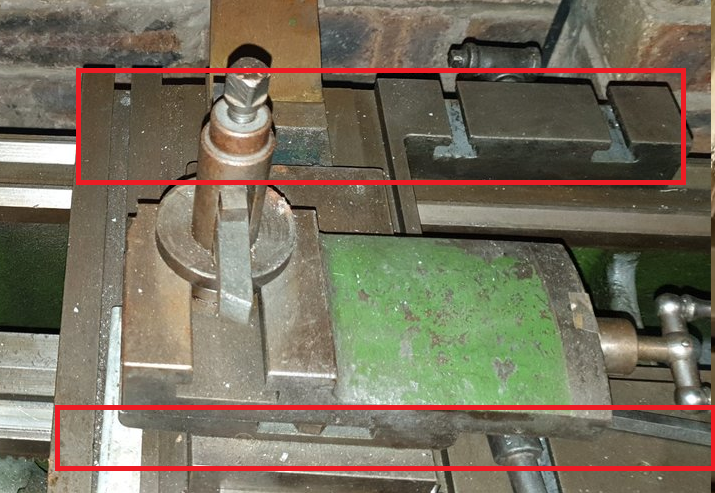

Then there is presumable a clamp on the far and near edges too. These probably bolt in from underneath, access may be from underneath and hard to get to where the apron gets in the way.

This is a different lathe but shows the clamping.

Then there is presumable a clamp on the far and near edges too. These probably bolt in from underneath, access may be from underneath and hard to get to where the apron gets in the way.

This is a different lathe but shows the clamping.

Pete.

Member

- Messages

- 14,570

- Location

- Kent, UK

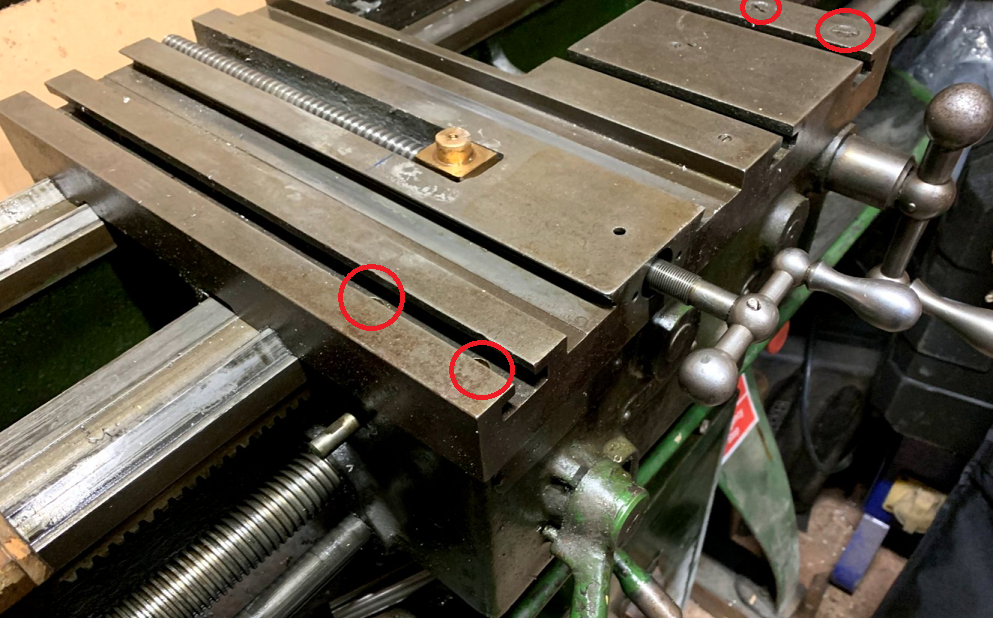

That is definitely separate saddle and apron. You have a pair of slotted screws in the bottom of the first tee slot on the left, and another pair on top of the saddl on the far right. Releasing those four screws will allow you to drop the apron. There are probably pins too.

prepman

Forum Supporter

- Messages

- 2,706

- Location

- Gwynedd UK

There are caphead screws in the teeways which suggests that it isn't one piece? Sorry someone beat me to it. I'm sure a leadscrew and nut plus gear can be organised for you on the forum? What size and pitch is the leadscrew? Remember to remove both power shafts before you drop the apron.So.... mixed news...

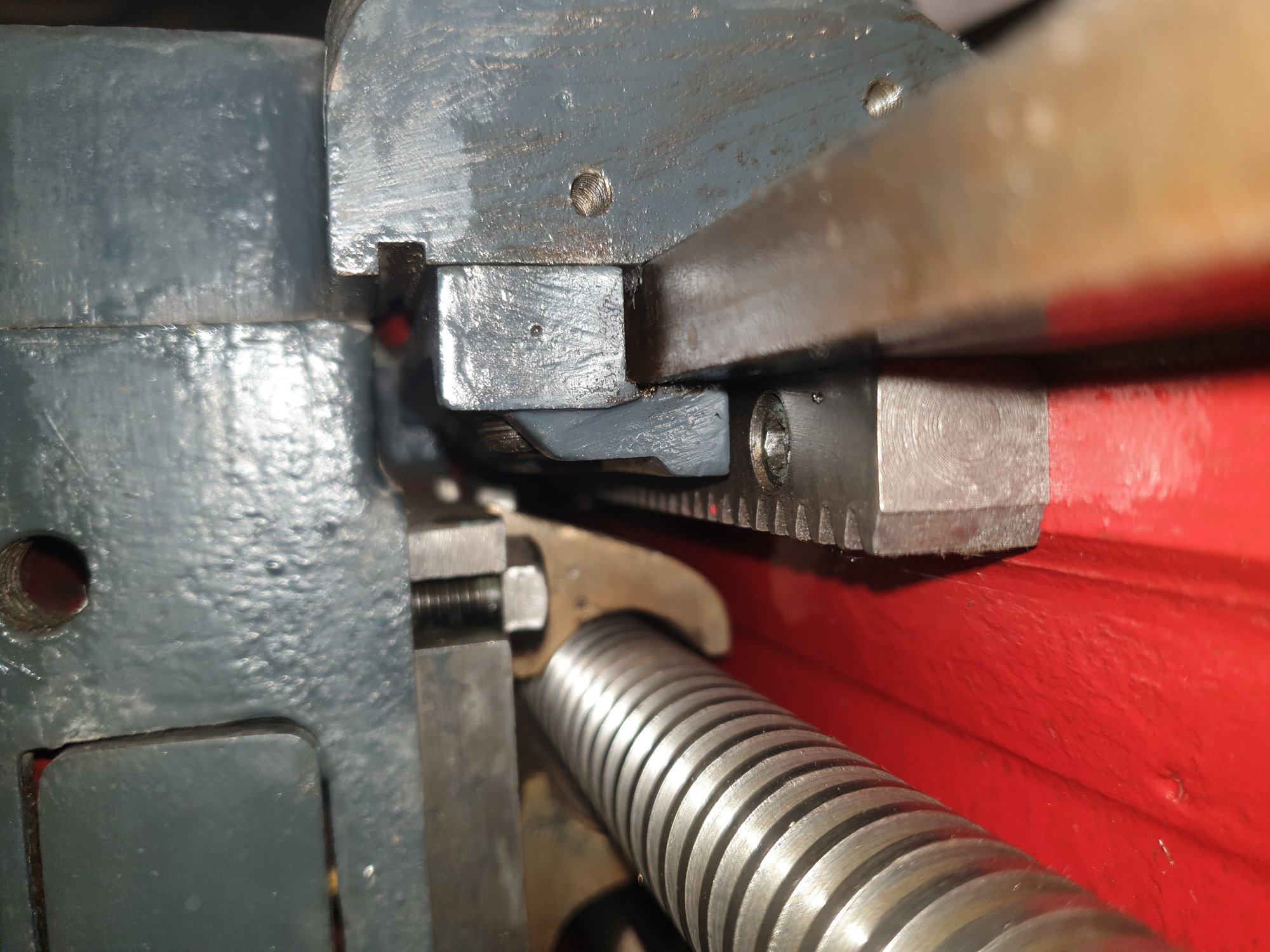

On the upside I reckon we have a diagnosis, which is that the transfer gear from the feedscrew to the cross slide screw has stripped (at least) a couple of teeth.

Continuing the (relatively) good news, the screw is straight and the brass nut seems undamaged.

Have a look at this (short! 50 seconds...) video to see the problem. The transfer gear is in permanent contact with the cross slide screw so it jars when winding in and out.

I reckon the only sensible short term fix is to remove the transfer gear entirely so that the cross slide rotates freely, at least until I can find a replacement (if possible for a 1930s lathe)

The not so good news is that the apron appears to be a single cast unit, not like the diagram that @500e helpfully posted above - https://www.mig-welding.co.uk/forum/threads/ive-broken-my-lathe.119144/post-2004747

You can hopefully see that in the video, too.

So I'm not sure how I'm going to dismantle it to get that gear off, at least not without picking the whole lathe up and rotating it, then trying to slide the apron off the end (as I'm short of space the right hand side of the lathe is up against shelves / a wall).

Thanks for the help so far - any more suggestions appreciated!

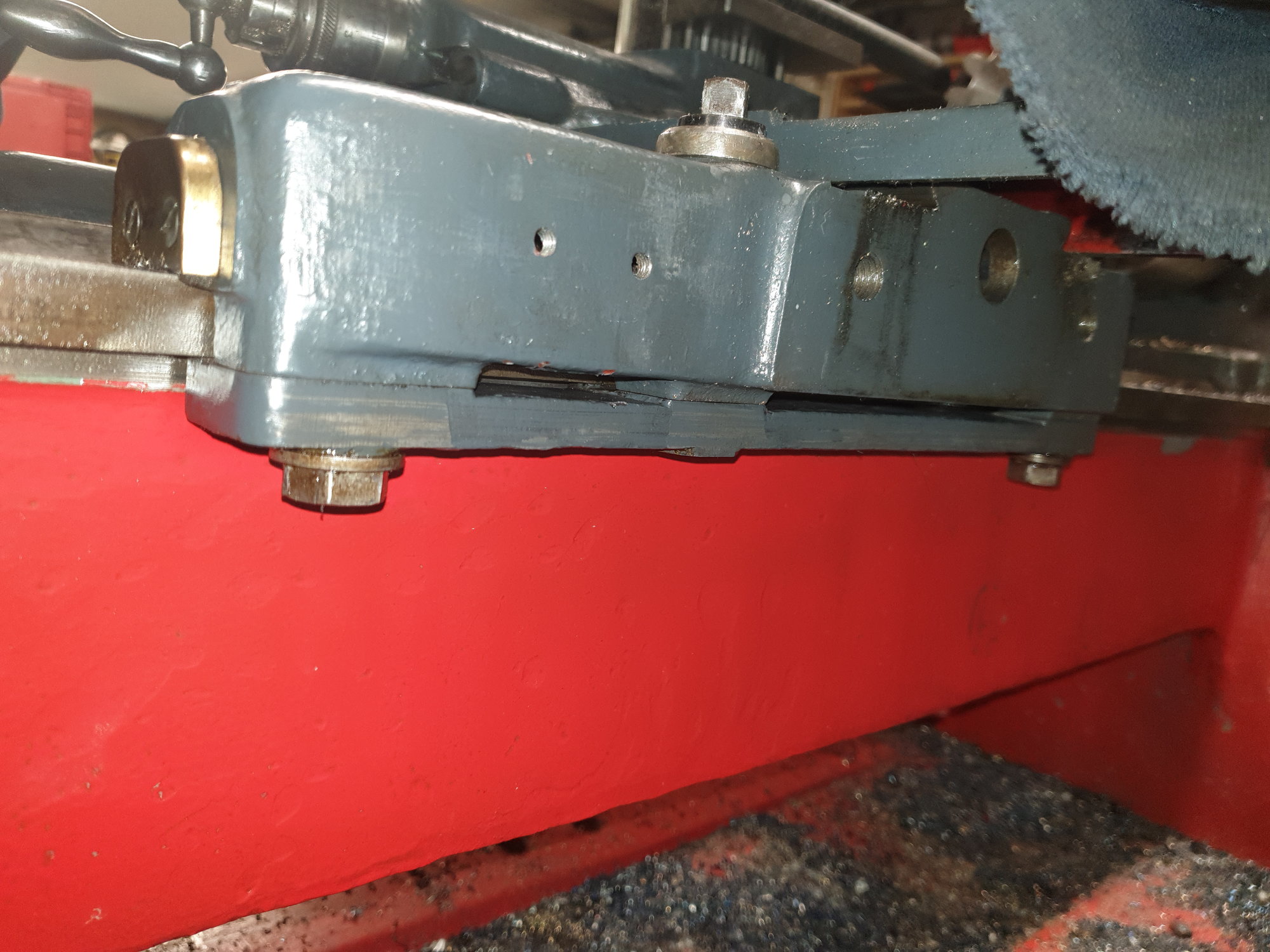

This is mine when replaced the feedshaft bushes. Yours will be similar. The interlock bolt in the pic I shortened so it could be removed without removing the worm gear.

Does the shaft rotate with the gear or the gear rotate on the shaft?

That should tell you if there is something holding the shaft in place or something holding the gear in place.

Quite a few of the Harrison gears have a grub screw holding them in place or where the shaft is fixed a grub screw holding it in place.

That should tell you if there is something holding the shaft in place or something holding the gear in place.

Quite a few of the Harrison gears have a grub screw holding them in place or where the shaft is fixed a grub screw holding it in place.

Last edited:

skotl

Forum Supporter

- Messages

- 9,969

- Location

- Edinburgh, UK

Shaft rotates with the gear - I've a suspicion that's what the hole is for in front of the gear, to get to a grub screw. But it was 11pm by the time I'd got to that point so chucked it in for the nightDoes the shaft rotate with the gear or the gear rotate on the shaft?

That should tell you if there is something holding the shaft in place or something holding the gear in place.

Quite a few of the Harrison gears have a grub screw them in place or where the shaft is fixed a grub screw holding it in place.

Pete.

Member

- Messages

- 14,570

- Location

- Kent, UK

The shaft and gear must be separate otherwise how did they fit it into a twin-walled apron. Besides it's an iron gear and almost certainly a steel shaft.

Rotate the gear and see if there's a grub screw in the side of the shoulder. If there is then that will be the retainer. There might be two at 90 degrees to each other or there might even be two in the same hole one on top of the other.

Rotate the gear and see if there's a grub screw in the side of the shoulder. If there is then that will be the retainer. There might be two at 90 degrees to each other or there might even be two in the same hole one on top of the other.

The other question, of course, is how to get the shaft out...

Could just be held in place by being attached to the gear.

Pete.

Member

- Messages

- 14,570

- Location

- Kent, UK

Could just be held in place by being attached to the gear.

That would be most likely give. The gear has extended shoulders to fill the gap.