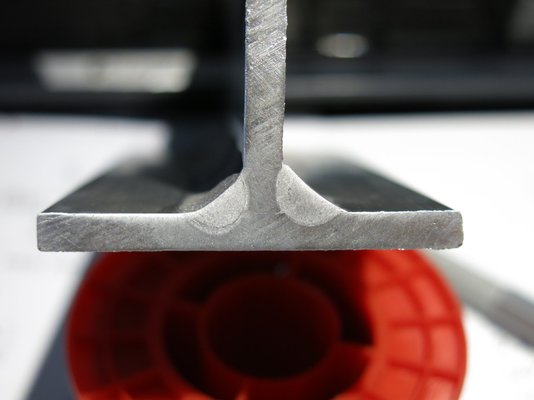

It's softer sheet ally and nothing broke but FWIW http://www.mig-welding.co.uk/forum/media/albums/ally-weld-abuse.743/I'd love to see a weld from somebody who knew what they are doing broken apart?.

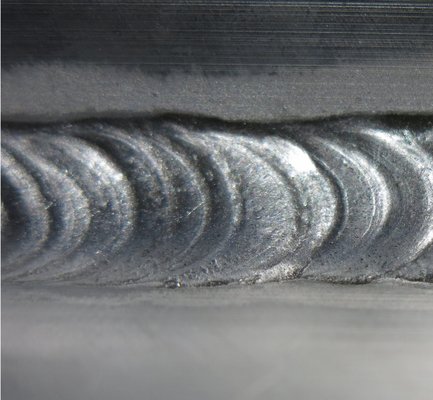

Using brute force or a BFH to attack/break welds on stuff is fairly limited in usefullness... on something like the soft sheet example above it kinda works as a ductility test but on heavier stuff and/or things made from tube/pipe it's kinda useless because in real life things fail from fatigue unless whoever designed the part got things very wrong. This is why destructive weld testing typically involves cutting samples from a weld coupon to subject to nick break tests, bend tests and inspection of etched samples

Attack a sound weld coupon with a BFH and, after getting FUBAR'ed it'll usually break in the HAZ so won't highlight any porosity or small areas of LOF etc [/gross generalisation]