I cant have a go tomorrow as I am having my grandson but the next day I will see if I have the right size mild steel and will try turning one and see how easy it is if its not bad i will do you 3From the ones I've replaced over the years they are going to be way too thick and not big enough in the major diameter , though I'm willing to look at it if you can suggest an engine vehicle with a big enough plug .

Earlier on tonight I've was checking out the cost of buying 4" MS stock bar to turn down to size & then turn to 1/2 " thick or so as per the idea of turning to size then working from the inside as in post #16 ... Who knows how long I'd be with my trusty SANDVIK hacksaw and , with my Blacker & Decker workmate MK2 trying to chop my way through those thicknesses..

Knowing how it was with the thin wall copper and aluminium tube I mentioned earlier it's sods law that the cutter would dig in and tear it all apart on the final cuts .

That's what I'd originally I'd considered but rejected it due to my lack of skills & disabilities , I'd need zillions of practice blanks to work with before I got it right I'm sure.

Waaah..... I'll just have to shopping in the post office with a shotgun and crash helmet at those prices , also see if there is still some Oofle dust in the , "Sooty's magicians set " that I got for Crimbo ..everything is possible with lots of Oofle dust .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

making dies for pressing cups

- Thread starter DAPPH

- Start date

DAPPH

as dyslexik as I'm daft

- Messages

- 7,012

- Location

- Near to Cross Hands Llanelli SouthWales GB

I'd love to Mike ,

however i don't have anything smaller than an ancient 180 turbo stick welder and the final wall size would need to be in 0.5 mm or there about so the deflector /cup can sit over the precision washer that retains the bearing cage ... it could be a bit problematic .

however i don't have anything smaller than an ancient 180 turbo stick welder and the final wall size would need to be in 0.5 mm or there about so the deflector /cup can sit over the precision washer that retains the bearing cage ... it could be a bit problematic .

DAPPH

as dyslexik as I'm daft

- Messages

- 7,012

- Location

- Near to Cross Hands Llanelli SouthWales GB

I cant have a go tomorrow as I am having my grandson but the next day I will see if I have the right size mild steel and will try turning one and see how easy it is if its not bad i will do you 3

Wow how generous .. Let me find the digi calipers tomorrow & make sure I do give you the correct measurements

Thanks

Dave

DAPPH

as dyslexik as I'm daft

- Messages

- 7,012

- Location

- Near to Cross Hands Llanelli SouthWales GB

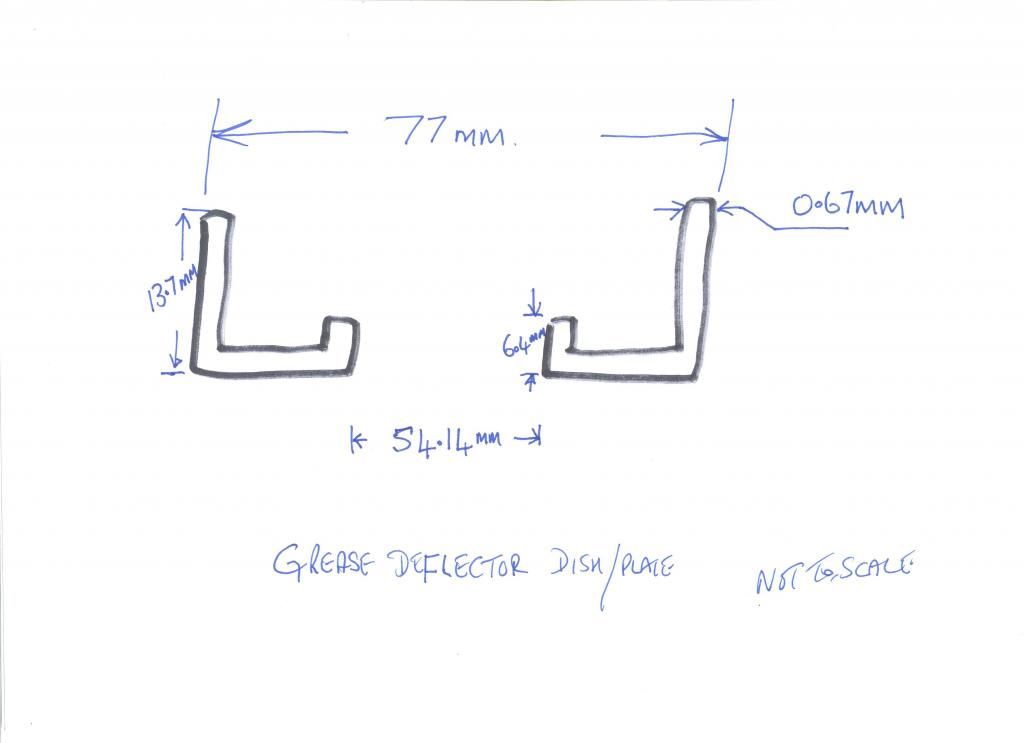

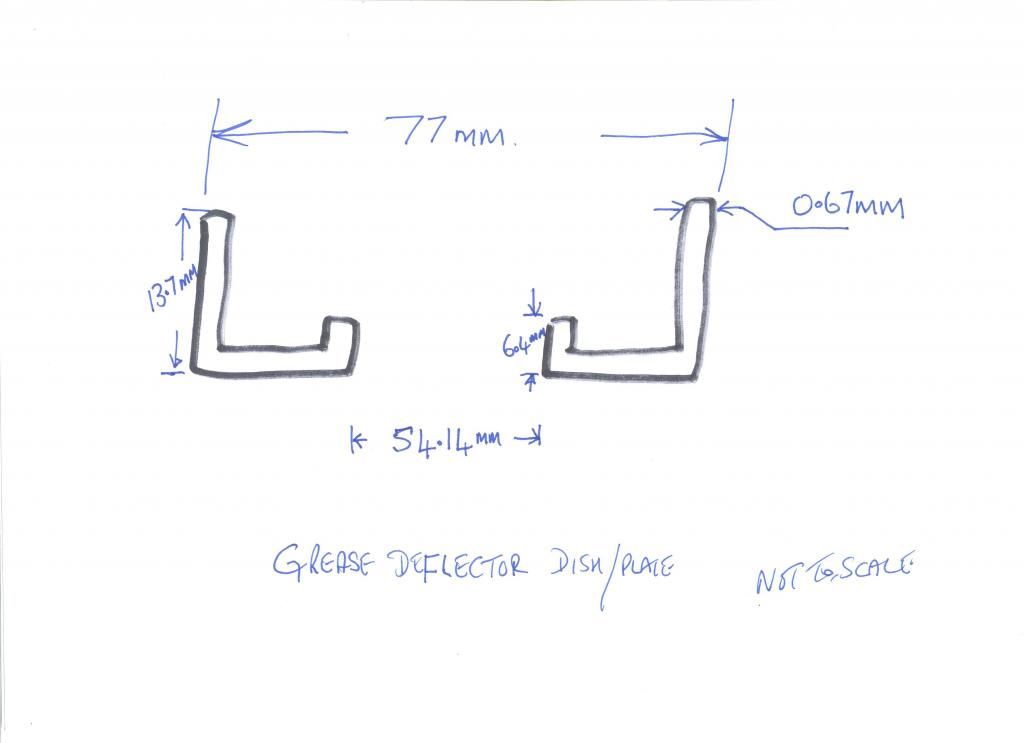

Please excuse the crud/e drawing  .

.

Whoops I edited it to put it in the correct orientation / plane ...looks like it's taken a dive .

Here are some photo's to clarify things .

Ignore the dimples and slits ..some so called , "Engineer " has implemented them over the last 70 years or so into the part .

This one shows the small witness hole/ slot on the right at 3 o'clock ( ish ) , it's for daily evacuation of dirty grease whilst the lathe is running nice & warmly after turning the grease " pump nut )" one turn at the start of each working day .

I can put this witness slot in on the caps myself .

Looking at the wrinkles in the metal in major lip I'd say the caps were pressed out via a couple of simple dies.

Any probs with anything , please let me know.

Many thanks

Dave

.

.Whoops I edited it to put it in the correct orientation / plane ...looks like it's taken a dive .

Here are some photo's to clarify things .

Ignore the dimples and slits ..some so called , "Engineer " has implemented them over the last 70 years or so into the part .

This one shows the small witness hole/ slot on the right at 3 o'clock ( ish ) , it's for daily evacuation of dirty grease whilst the lathe is running nice & warmly after turning the grease " pump nut )" one turn at the start of each working day .

I can put this witness slot in on the caps myself .

Looking at the wrinkles in the metal in major lip I'd say the caps were pressed out via a couple of simple dies.

Any probs with anything , please let me know.

Many thanks

Dave

DAPPH

as dyslexik as I'm daft

- Messages

- 7,012

- Location

- Near to Cross Hands Llanelli SouthWales GB

Ok mate thats good enough for me, lets see how good I am ..lol

Did you have a play ?

My man cupboard is now almost back to a working one , It's been out of comission since 21 Dec 2014 , now after a full three wall build in thermal block , new roof joists , new 150 mm thick insulated roofing panels, new up& over door frame and 14 new double switched 13 amp sockets ,

I'm just waiting for the arrival of a pair of the the latest 1500 mm long LED clear sealed tube warm light led tubes ( fluorescent replacements ) to arrive then I'll be having a go at making the forms/dies for pressing them out .

PS It looks like Santa didn't find the cupboard on the 25 Dec so is sending his elves a few weeks later with some nice toys for my cupboard instead .

Sadly not yet mate. I have cut a blank ready and had free day today but we have all been suffering from this bug/virus that keeps making you feel as rough as a badgers $%^& and as weak as a kitten. All cold and shivery together with a headache even though the heating is on full.

I feel a bit better today but my wife is really suffering (she is weak following a stroke, so she seems to catch anything going round.) My son had it first 3 weeks ago and keeps thinking its gone but he was really ill last night but does not live with us...

If my wife gets better either tomorrow or Wednesday (Baby sitting tuesday) I will get back in garage

I feel a bit better today but my wife is really suffering (she is weak following a stroke, so she seems to catch anything going round.) My son had it first 3 weeks ago and keeps thinking its gone but he was really ill last night but does not live with us...

If my wife gets better either tomorrow or Wednesday (Baby sitting tuesday) I will get back in garage

DAPPH

as dyslexik as I'm daft

- Messages

- 7,012

- Location

- Near to Cross Hands Llanelli SouthWales GB

Take it easy ,look after your lass , whatever you do don't go a playing on any machinery if you're like that .

If it's the same thing we as a family have had , it's laid us low for the best part of six weeks , My 13 yr old has had it longest , for her it kicked off 30 Nov . She missed school till they stopped for Christmas & is still as pale as skimmed milk , she's lost 9 pounds ( you'd wonder how she managed to find that much to lose as shes that wiry .

She's now developed a hacking cough that she never had before the event. At the school there are no end of other kids off with whatever this thing is . Alison & I seem to be on the mend but today both of us went duvet diving for a few hours ( At different times

At different times  )

)

If it's the same thing we as a family have had , it's laid us low for the best part of six weeks , My 13 yr old has had it longest , for her it kicked off 30 Nov . She missed school till they stopped for Christmas & is still as pale as skimmed milk , she's lost 9 pounds ( you'd wonder how she managed to find that much to lose as shes that wiry .

She's now developed a hacking cough that she never had before the event. At the school there are no end of other kids off with whatever this thing is . Alison & I seem to be on the mend but today both of us went duvet diving for a few hours (

At different times

At different times  )

)DAPPH

as dyslexik as I'm daft

- Messages

- 7,012

- Location

- Near to Cross Hands Llanelli SouthWales GB

Langy, how would you stop the welder burning though the 0,5 mm metal ?

Now I'm gaining confidence & competence with my lathe I may now have the solution .

Yesterday I managed to turn a lump of 2 " bar into 42mm OD , 41.046 mm ID for a distance of 17 mm internal at one end . It surprised me , for my antique lathe is ten years older than me at 74 years old .

It looks like I should be able to use a 100 mm long slug of 80 or 85 mm bright steel bar turned between centres , to get the thing made .

Now I'm gaining confidence & competence with my lathe I may now have the solution .

Yesterday I managed to turn a lump of 2 " bar into 42mm OD , 41.046 mm ID for a distance of 17 mm internal at one end . It surprised me , for my antique lathe is ten years older than me at 74 years old .

It looks like I should be able to use a 100 mm long slug of 80 or 85 mm bright steel bar turned between centres , to get the thing made .

DAPPH

as dyslexik as I'm daft

- Messages

- 7,012

- Location

- Near to Cross Hands Llanelli SouthWales GB

YUP , my confidence in the lathe & my skills have improved somewhat since then , for I've had a few hours play on the lathe most days since my man cupboard was finished .

The pressed steel still seems viable & the correct way forward , as it should have some spring in the outer lip to give a sound grip in the reamed casing where the bearing lies.

I did make two spun aluminium caps on my ancient lathe without any problem whatsoever , using two empty cut up ladies underarm spray can , each can made a 0.4 mm thick sheet about six wide x seven inches tall .

My forms were made out of some new planed floor joist off cuts , the wood was very damp and fibrous so they were not really accurate by any way of thinking . They were however fairly easy to do ,now I'm having to wait for the ladies of the home to empty two more cans ( another two months or so ) for the inner lip was not quite deep enough to do the job . I'd made the basic template centre hole too big so the lip was foreshortened due to a the lack of material present , it also split /feathered out a bit .

Maybe I'll need thicker ally next time & have to anneal it with fairy soap and a blow lamp ???

Fortunately I now have some large hard industrial plastic rounds ( freebies with the opportunity of more just for the collecting ) that are like ice hockey pucks & are nearly seven inches O/D and 25 , 35 or 40 mm or so thick , it turns like a dream . To continue expanding my skills & knowledge I may make some new more precise forms from this material and then try the spinning again .

The spinning was quite an interesting exercise , it can only improve, especially if I can get ball ends on the forming bars like smooth ball bearings . That gives rise to another challenging & interesting project .... making a small ball turner to turn a ball on a turned 60 mm waisted 15 to 19mm rod at both ends and make one of the waisted ends ( heat formed )slightly angled to about 60 degrees so it can be used to make deeper internals maybe even to the extent of having to use two part flat bolted up disks as a complex form to spin into .

The pressed steel still seems viable & the correct way forward , as it should have some spring in the outer lip to give a sound grip in the reamed casing where the bearing lies.

I did make two spun aluminium caps on my ancient lathe without any problem whatsoever , using two empty cut up ladies underarm spray can , each can made a 0.4 mm thick sheet about six wide x seven inches tall .

My forms were made out of some new planed floor joist off cuts , the wood was very damp and fibrous so they were not really accurate by any way of thinking . They were however fairly easy to do ,now I'm having to wait for the ladies of the home to empty two more cans ( another two months or so ) for the inner lip was not quite deep enough to do the job . I'd made the basic template centre hole too big so the lip was foreshortened due to a the lack of material present , it also split /feathered out a bit .

Maybe I'll need thicker ally next time & have to anneal it with fairy soap and a blow lamp ???

Fortunately I now have some large hard industrial plastic rounds ( freebies with the opportunity of more just for the collecting ) that are like ice hockey pucks & are nearly seven inches O/D and 25 , 35 or 40 mm or so thick , it turns like a dream . To continue expanding my skills & knowledge I may make some new more precise forms from this material and then try the spinning again .

The spinning was quite an interesting exercise , it can only improve, especially if I can get ball ends on the forming bars like smooth ball bearings . That gives rise to another challenging & interesting project .... making a small ball turner to turn a ball on a turned 60 mm waisted 15 to 19mm rod at both ends and make one of the waisted ends ( heat formed )slightly angled to about 60 degrees so it can be used to make deeper internals maybe even to the extent of having to use two part flat bolted up disks as a complex form to spin into .