scottmk1

Member

- Messages

- 1,986

- Location

- Scotland

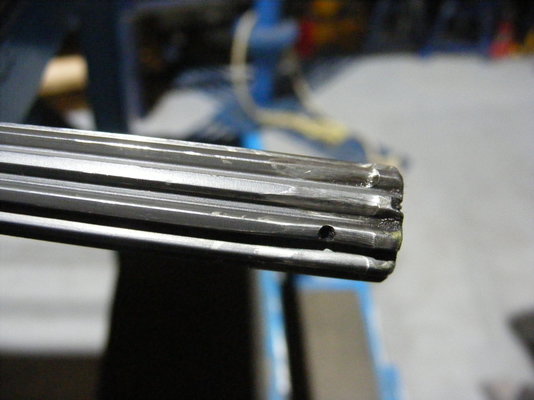

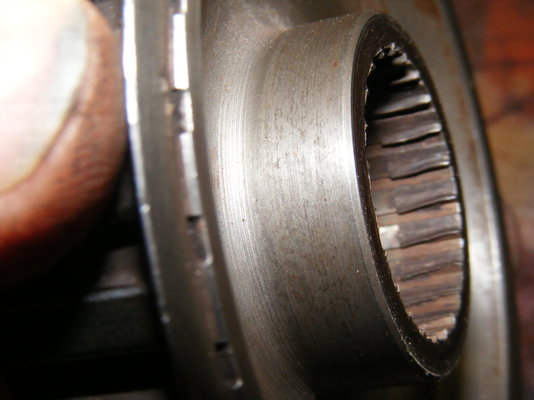

So the part of my milling machine saga is the spindle, the splines are worn in one particular area where the hub that drives it makes contact when the quill is fully retracted. The area of wear is around 60-70mm long and it’s probably 1-1.5mm deep.

This is an expensive part to buy, £1750 to be precise, so I’m looking at possible repair options. What’s the thoughts on brazing or building up with a metalizing spray? Would the risk of distortion be too much? If so what other suggestions do people have?

This is an expensive part to buy, £1750 to be precise, so I’m looking at possible repair options. What’s the thoughts on brazing or building up with a metalizing spray? Would the risk of distortion be too much? If so what other suggestions do people have?