julianf

Member

- Messages

- 8,238

- Location

- devon, uk

what battery is it? size and model

M18 5ah

I think that makes it a B5?

what battery is it? size and model

Probably more cost effective to get a new one at that spec. But that's no fun is it.

They open up quite easily if you drop them on concrete, saves the little torque tools. Guess how I know. Quite surprising how little and short those screws are. Not gripping on much at all.About £60. And its not even been hammered. I mean its been used regularly, but not that many cycles. Feel a bit hard done by, but, sure, no point in throwing good money after bad.

All ways worth a call to importers/manifacturers having a polite complain

Suprised what it can do

Curiosity got the better of me, partially because I already the right torx bits out on my desk from earlier

Voltages (left to right)

overall 16.21

4.05

4.05

4.05

0.00

4.05

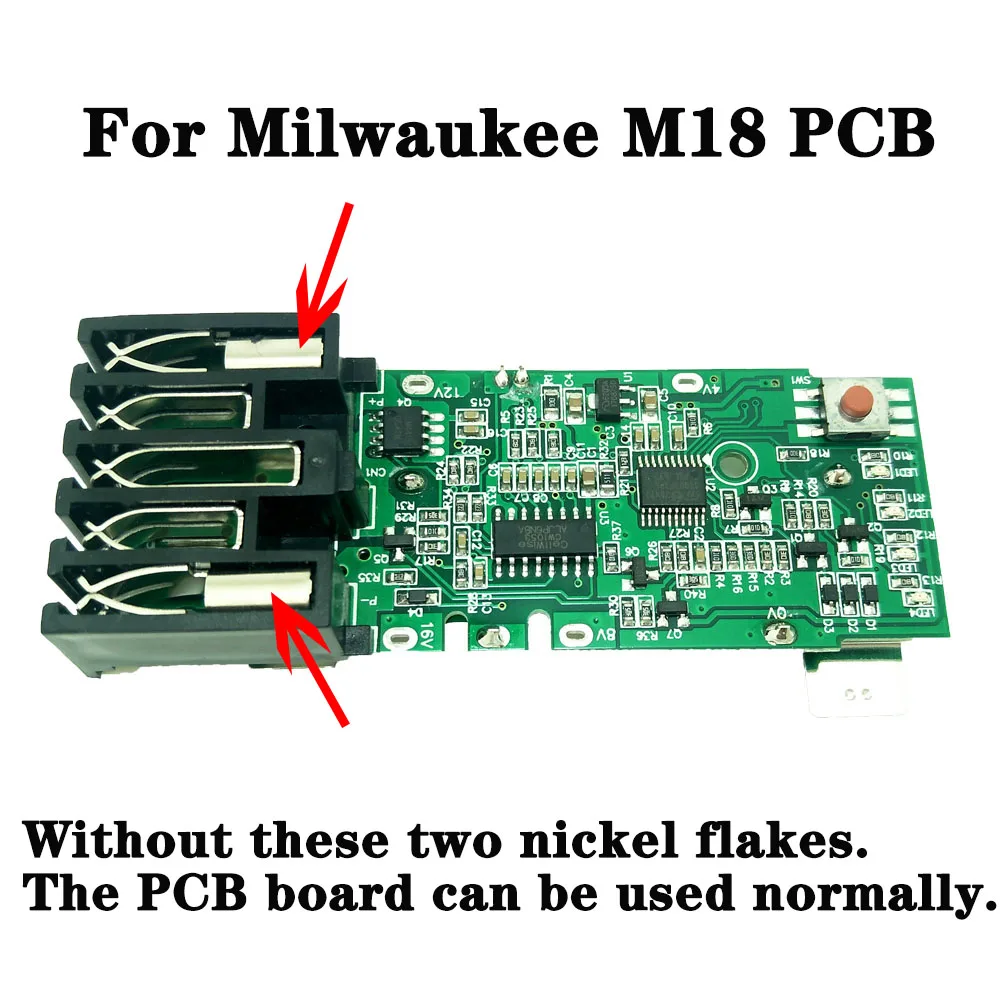

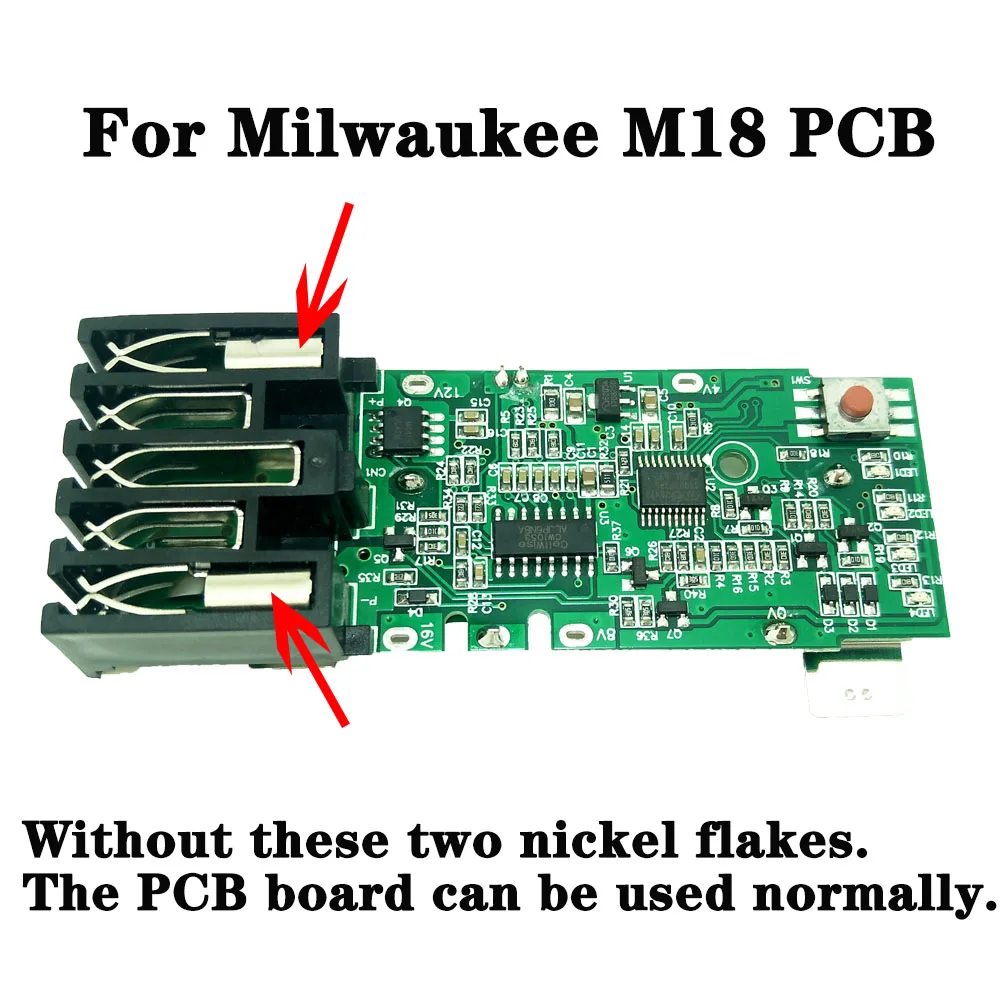

So Low Volts has become No Volts and the cells are welded in pairs.

Well it looks like a weld but I might stick a small flatblade under the terminal and see if it actually is welded

Would be a bonus if that is just a sprung terminal

View attachment 316773

Radio Control battery chargers.rc charger ?

I fed the two low ones 5v at 200ma, CPC lists the charging voltage as 4.2 so maybe the cells are baked now rather than a bit low.

Maybe I should have looked up a charging voltage before that but I didn't know the cell type.

Hindsight is great.

The specs on them are impressive, peak current of 25A, I can see how these micro jump packs can step up to cranking an engine and still fit in a pencil case.

The best (cheapest) way to solder tabs back on is to use a decent 12 volt Field Soldering iron with massive tip.Ive split up a number of 18650 cells, and that is a spot weld.

You can buy specific machines for sticking back on the tabs, but they are over a hundred quid...

If you find an old laptop battery, that will have similar - you may be able to recover a working cell from that with the spot welds in place, and cut the tab further away from the cell itself - then cut the M18 to match - that would then allow you to join the metal work, rather than solder to the cell. So you keep the heat away from the cell.

Just a thought.