rtbcomp

Moderator

- Messages

- 18,549

- Location

- Sheffield UK

I use crushed glass for blasting and while it breaks down easily it remains sharp. This means it's still useable when it reaches the consistency of flour!

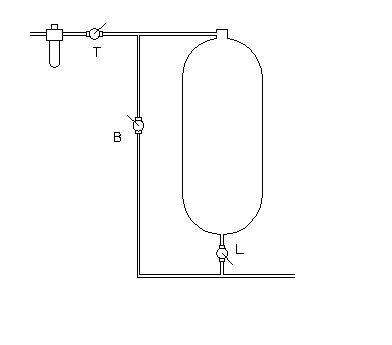

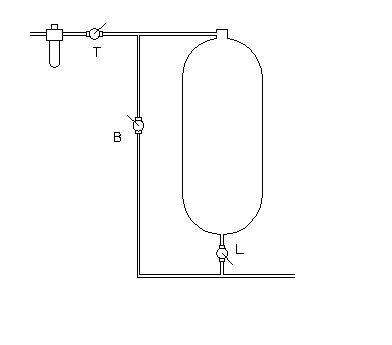

However such fine media sticks in the pot. I found I could get it to feed better by slightly closing the valve 'B' in the diagram below.

This increases the pressure in the pot, but reduces the flow through to the nozzle and hence the blasting force.

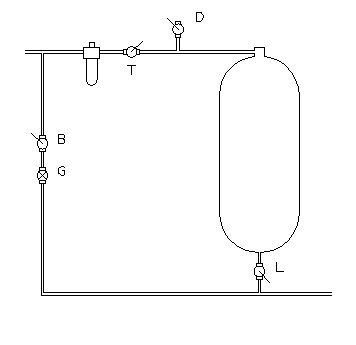

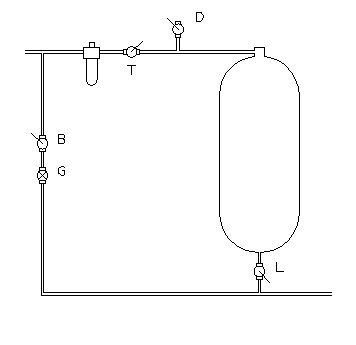

So I reconfigured the plumbing as follows

I've found that by setting the regulator to 4-5 bar and adjusting the flow with the gate valve 'G' I get a much more even flow of grit and at a greater force.

Surging, where the grit comes out too quickly and blocks the nozzle, is almost eliminated which means I get more useful blasting from a full pot.

The ball valve 'B' cuts off the airflow so I can leave the gate valve set. Closing 'B' momentarily will clear any blockage at the lower valve 'L'.

Closing valve 'T' and opening 'D' de-pressurises the pot for filling. Leaving 'D' open during filling lets the air out as the media enters the pot, making filling easier.

However such fine media sticks in the pot. I found I could get it to feed better by slightly closing the valve 'B' in the diagram below.

This increases the pressure in the pot, but reduces the flow through to the nozzle and hence the blasting force.

So I reconfigured the plumbing as follows

I've found that by setting the regulator to 4-5 bar and adjusting the flow with the gate valve 'G' I get a much more even flow of grit and at a greater force.

Surging, where the grit comes out too quickly and blocks the nozzle, is almost eliminated which means I get more useful blasting from a full pot.

The ball valve 'B' cuts off the airflow so I can leave the gate valve set. Closing 'B' momentarily will clear any blockage at the lower valve 'L'.

Closing valve 'T' and opening 'D' de-pressurises the pot for filling. Leaving 'D' open during filling lets the air out as the media enters the pot, making filling easier.

that answers that question then , it should have been shown as well

that answers that question then , it should have been shown as well