zardoz

Old school Socialist

- Messages

- 2,217

- Location

- Chetser, UK

Here are some pics of my efforts at TIG at my evening class city & guilds level 2. I appologize for the pics i made the rookie mistake of taking them in bright sunlight1 (You wouldnt think i actually have an A level in photography !) If you cant see them properly let me know and i will take some others.

They are numbered 1 to 9. Over the period of 6 weeks I did them, these are a representation of my progress. The steel was 1.6mm plate. The flat welds had purge gas to rear, welded on a jig. The vertical welds had no purge and were just done clamped to a vice.

First here is the machine I do all my work on. A Miller synchcrowave 300

------------------------------------------------------------------------------------------------

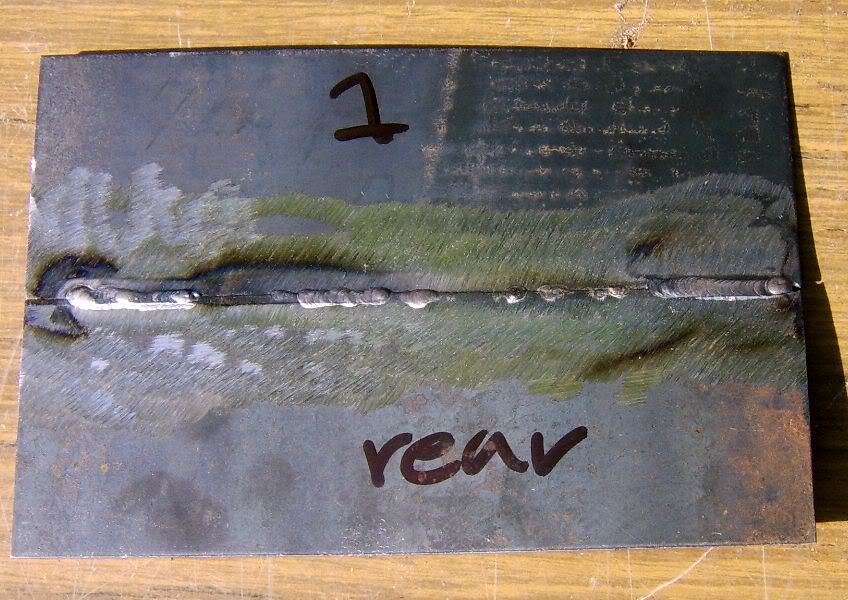

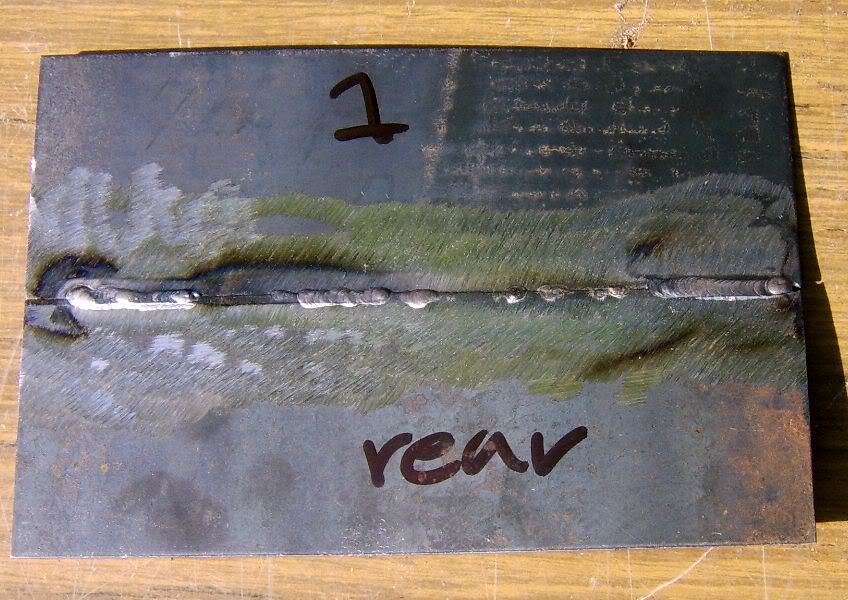

Here is effort 1 front and back.Pretty rubbish and no penetration on the rear of weld.

Weld 2, slightly better weld but no penetration whatsoever, in other words worthless!

Weld 3, slightly better weld though a bit wobbly. penetration a bit better but still way off.

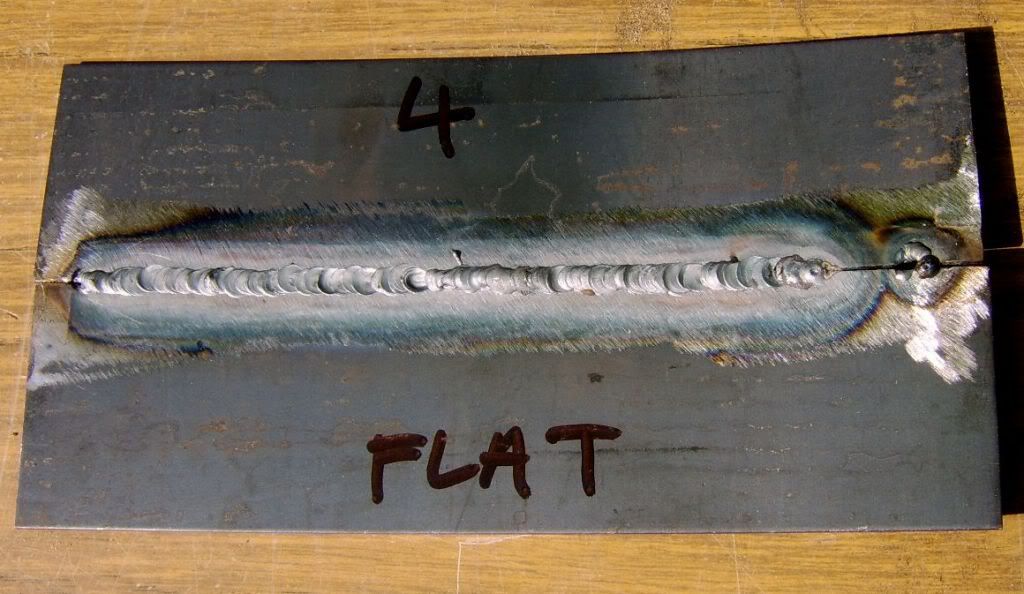

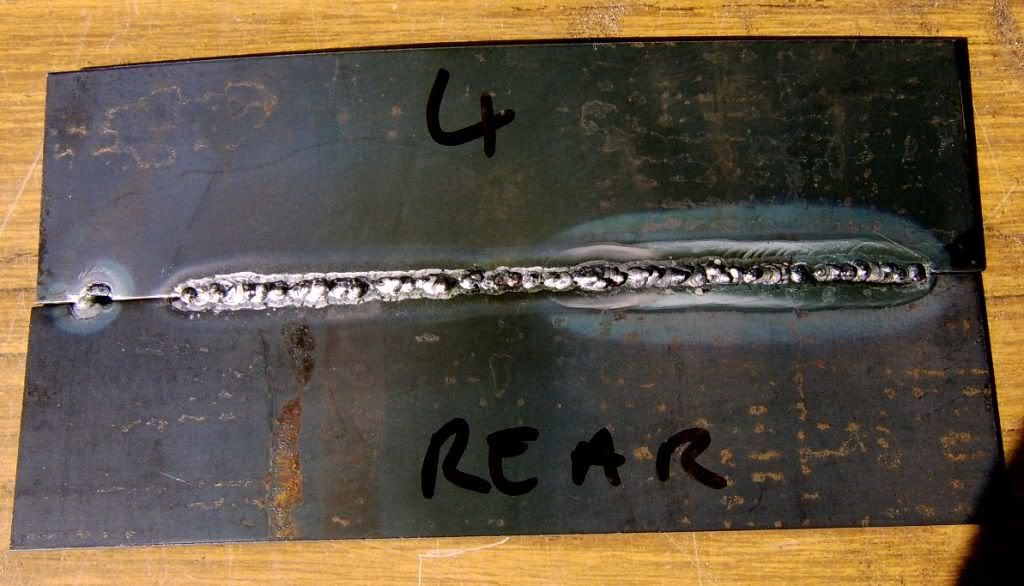

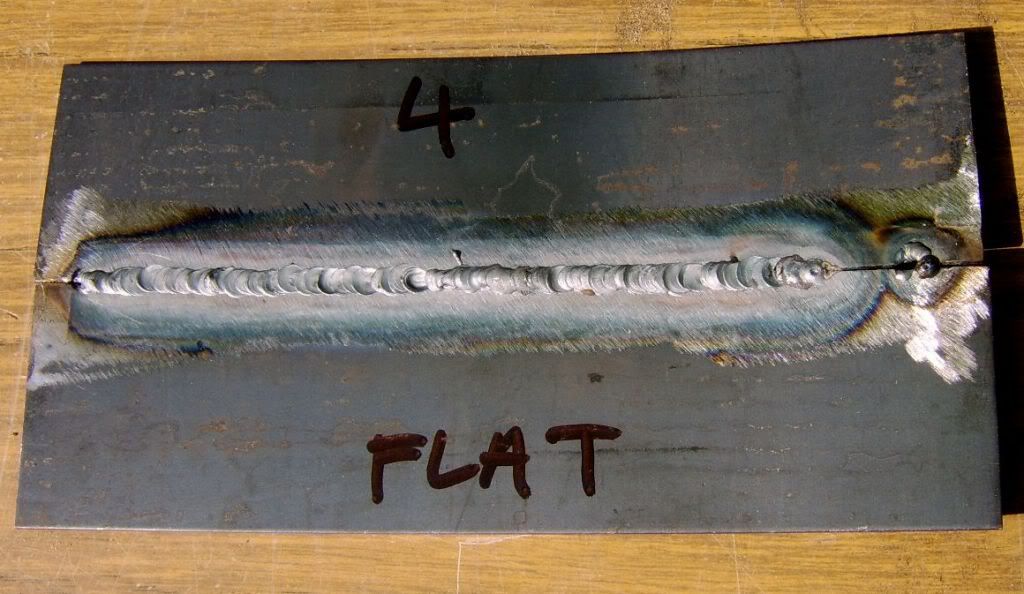

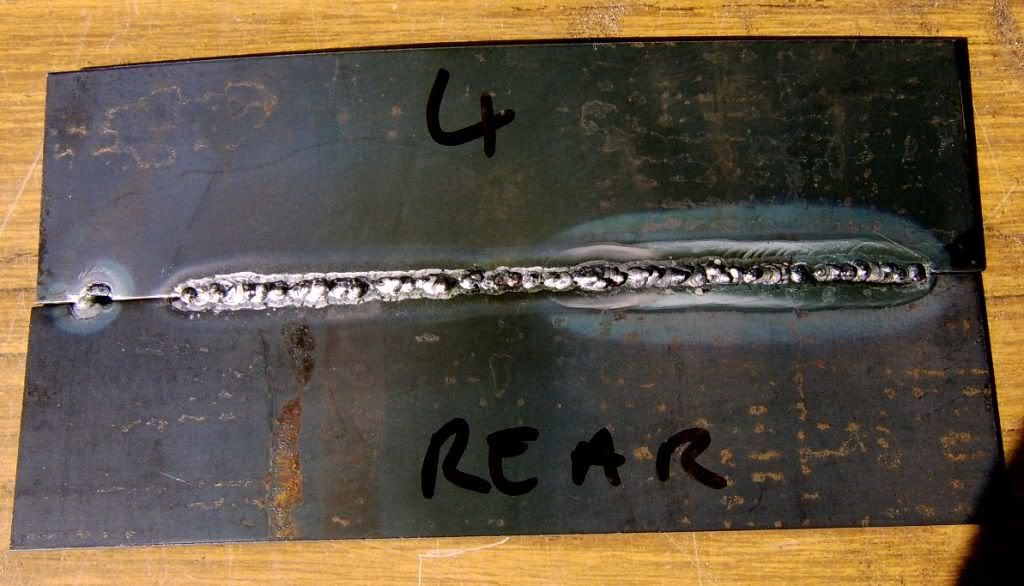

Weld 4 is a better less messy weld with again better pen to the rear. (This is what the tutor laughingly calls "A mechanics weld")

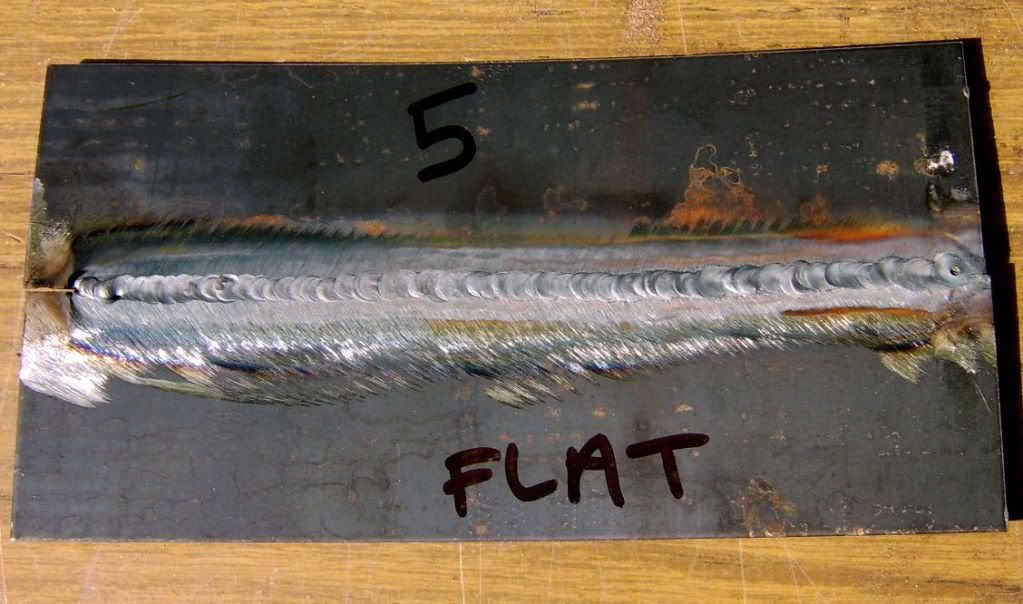

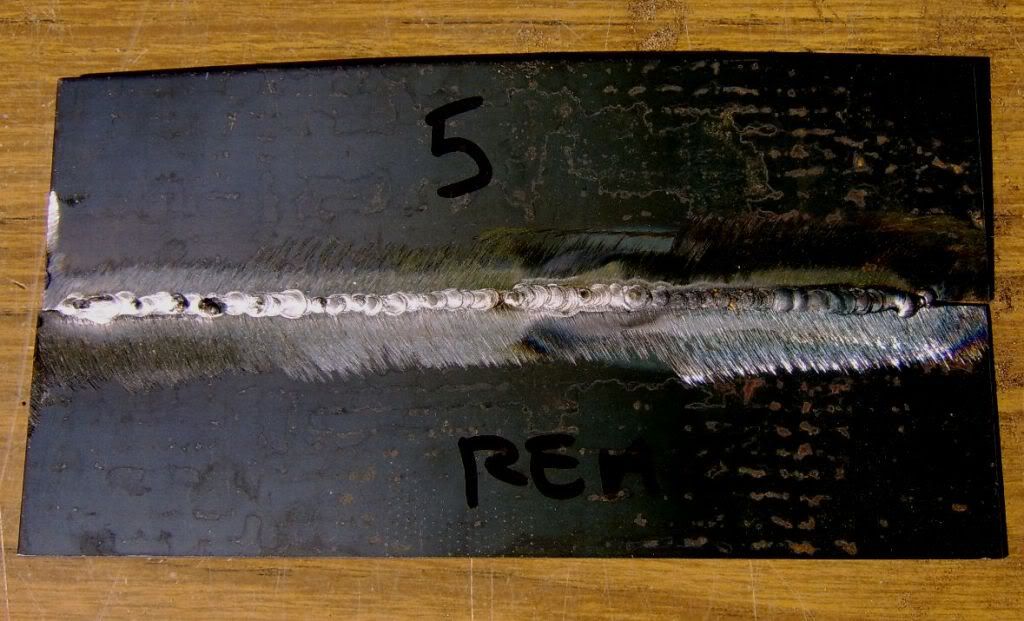

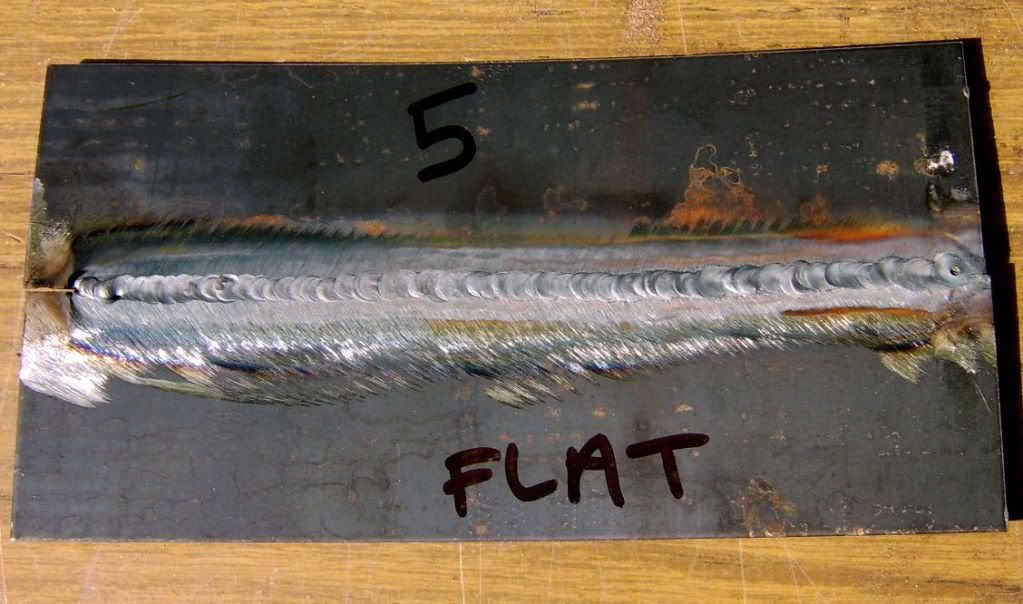

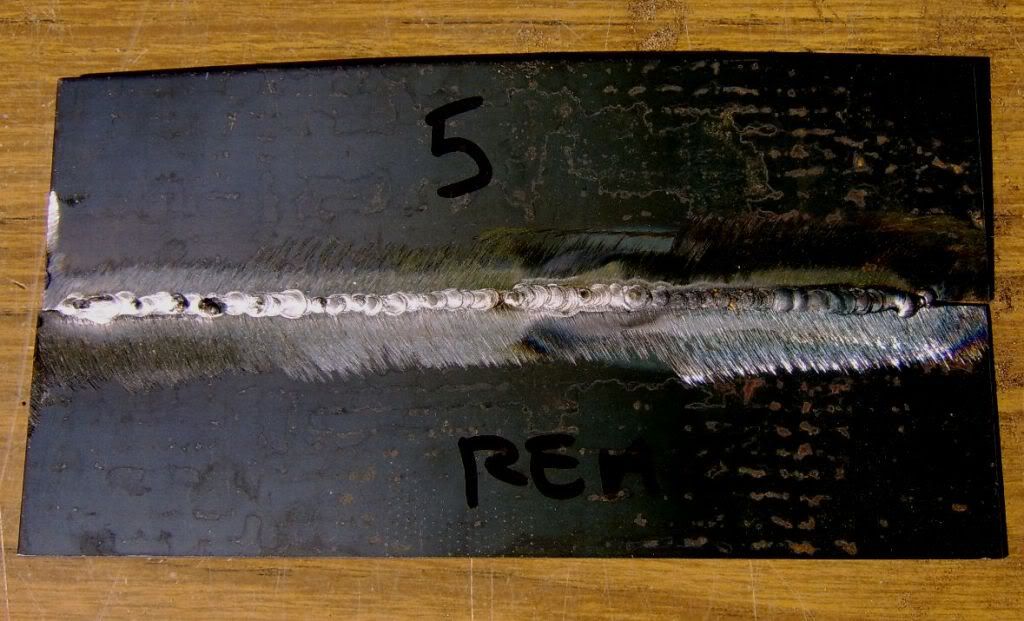

Weld 5, again a small improvement, but still a way to go.

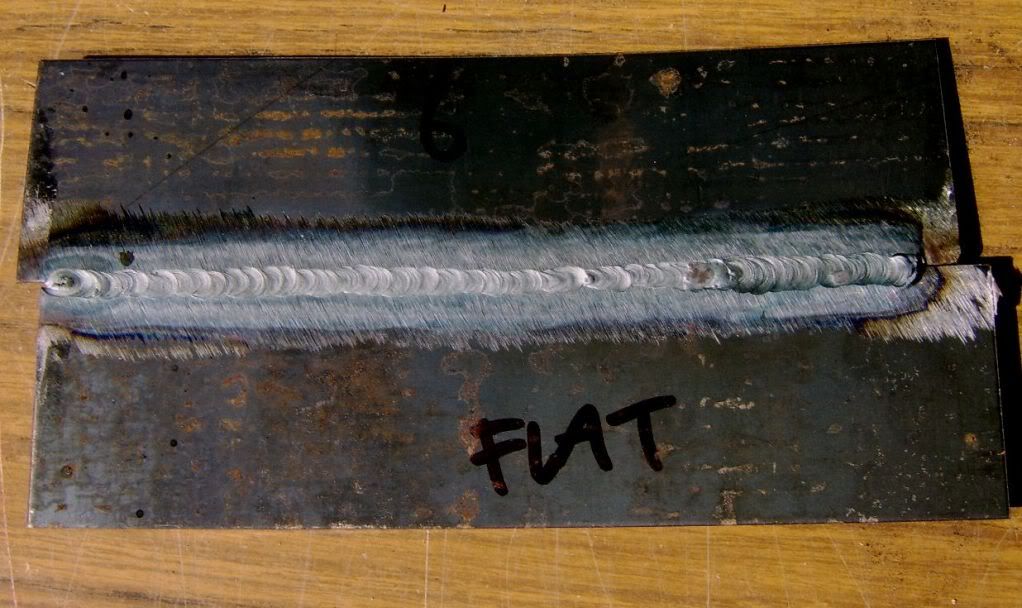

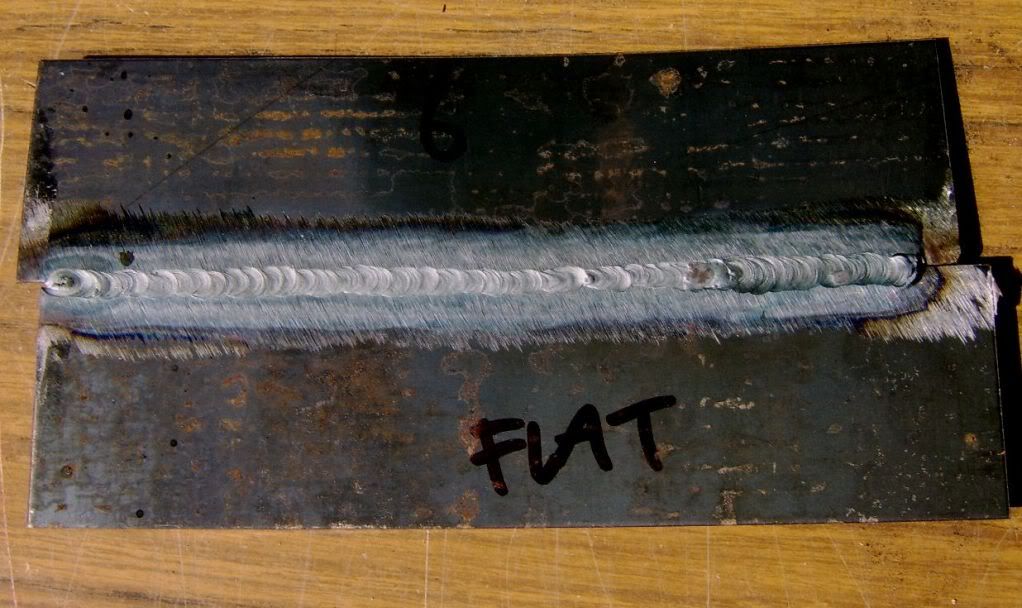

Weld 6. By now i was getting well peed off. I could do a reasonable weld though I could not seem to get constant penetration all the way along.

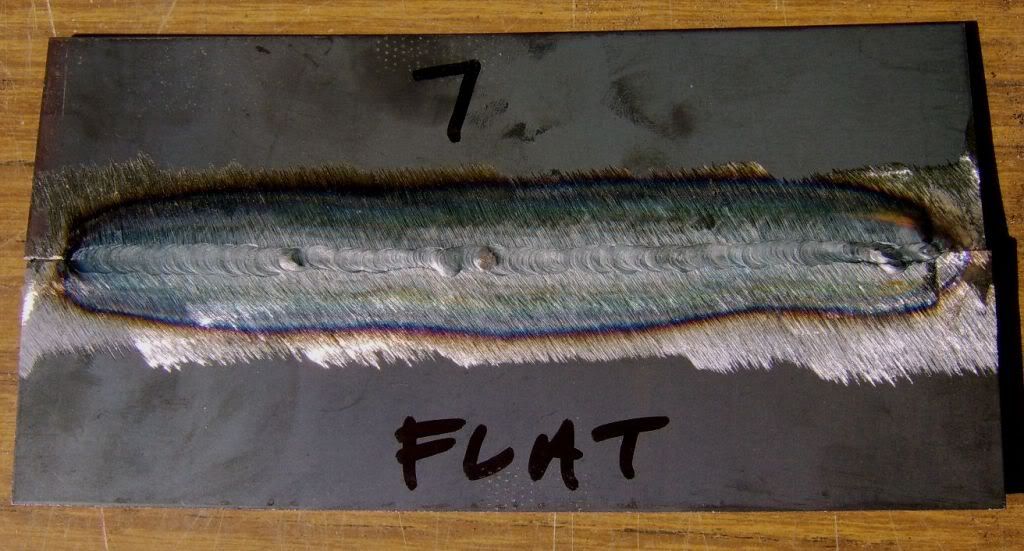

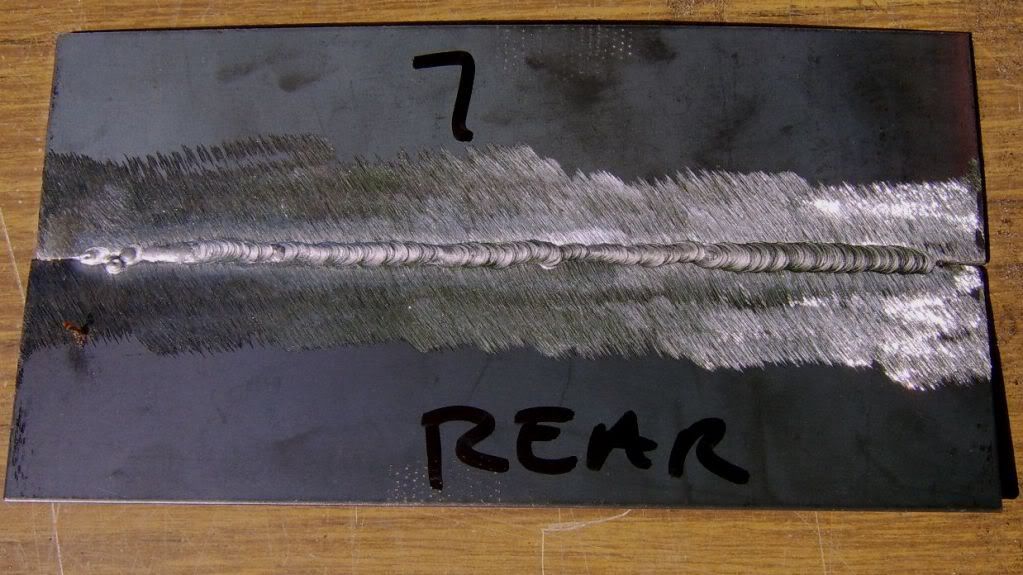

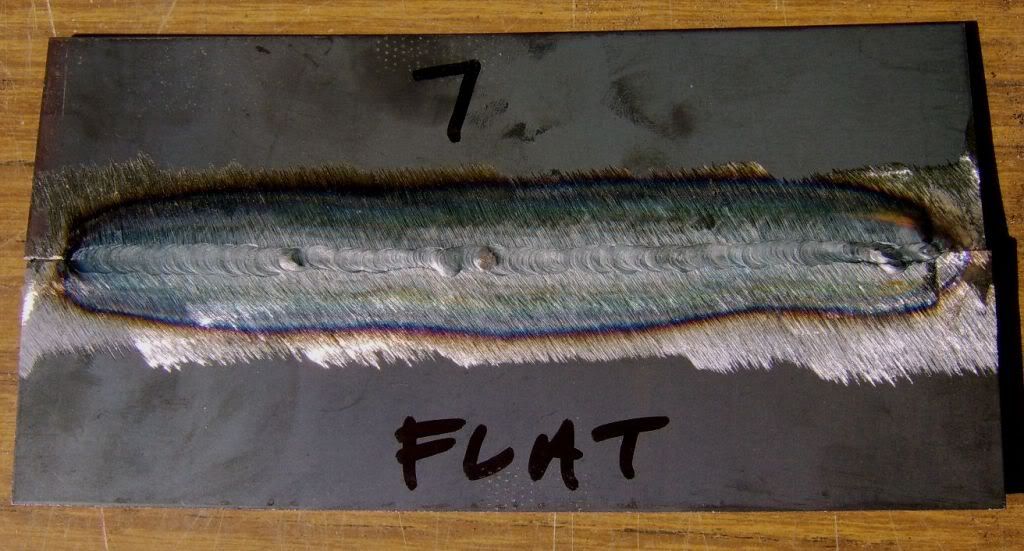

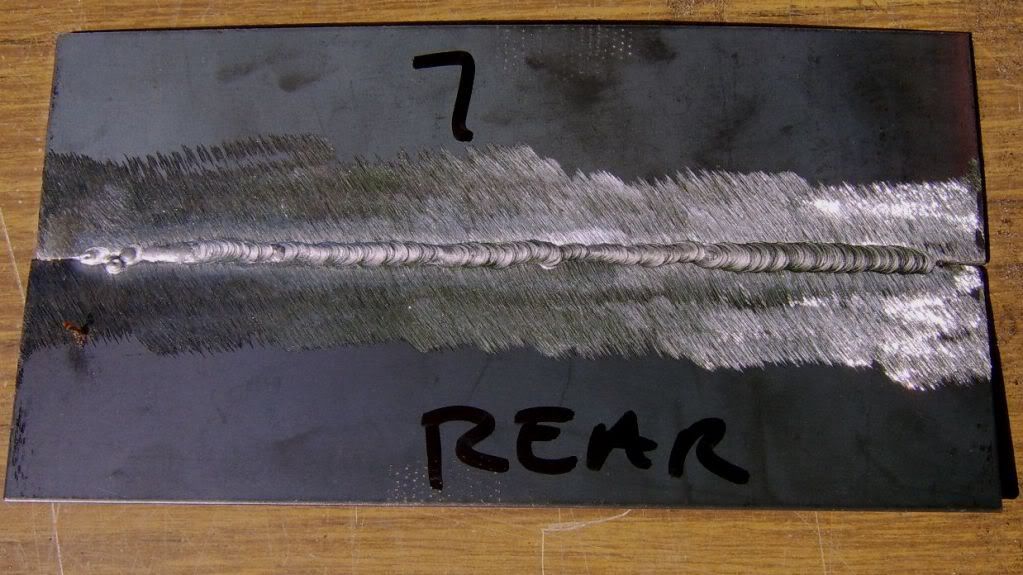

Weld 7. Could it be true? I nearly had a good weld of an entire 8 inch run ?

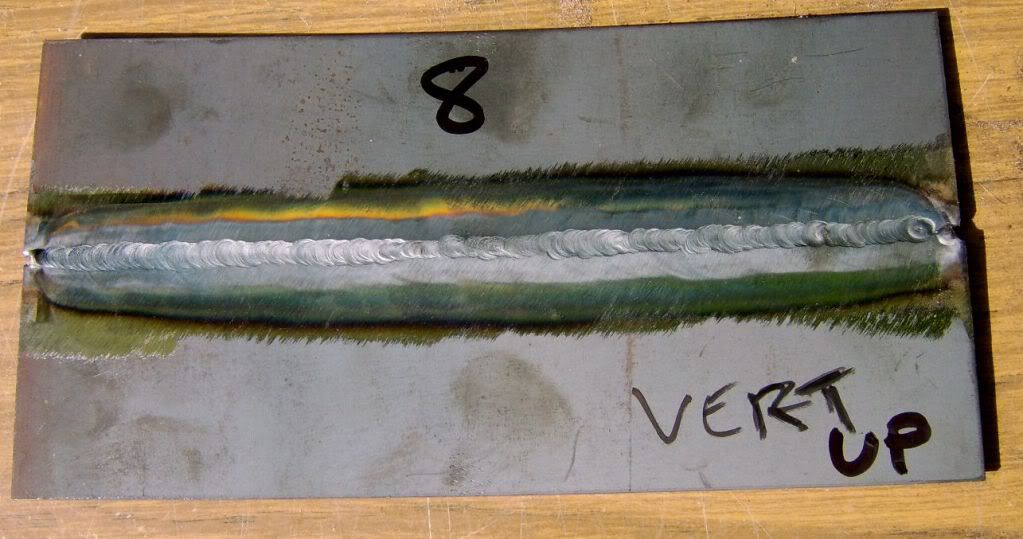

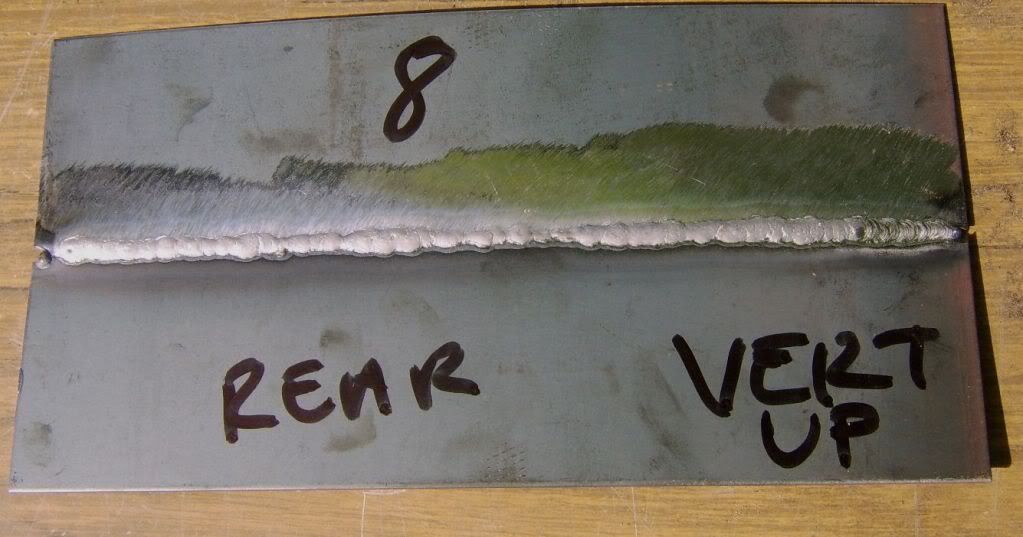

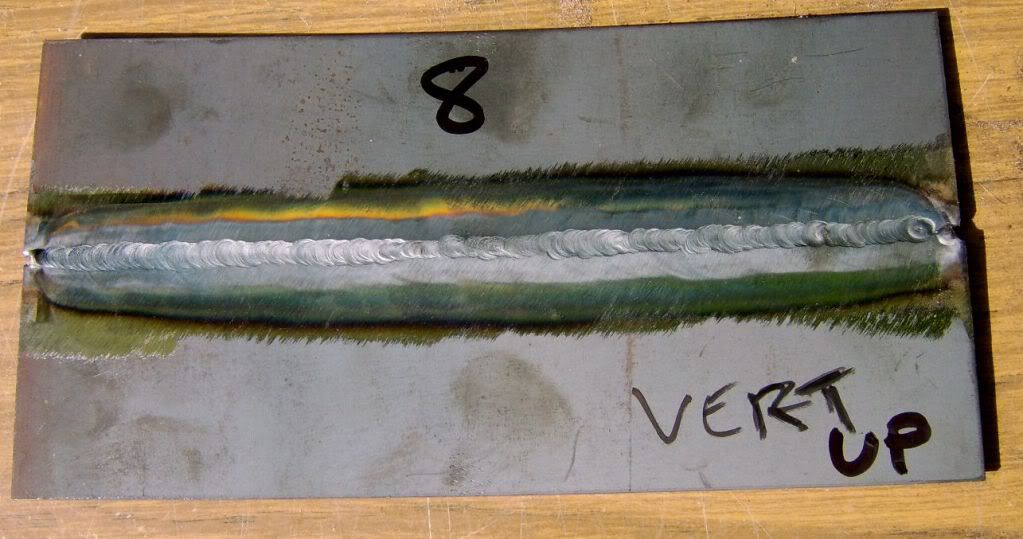

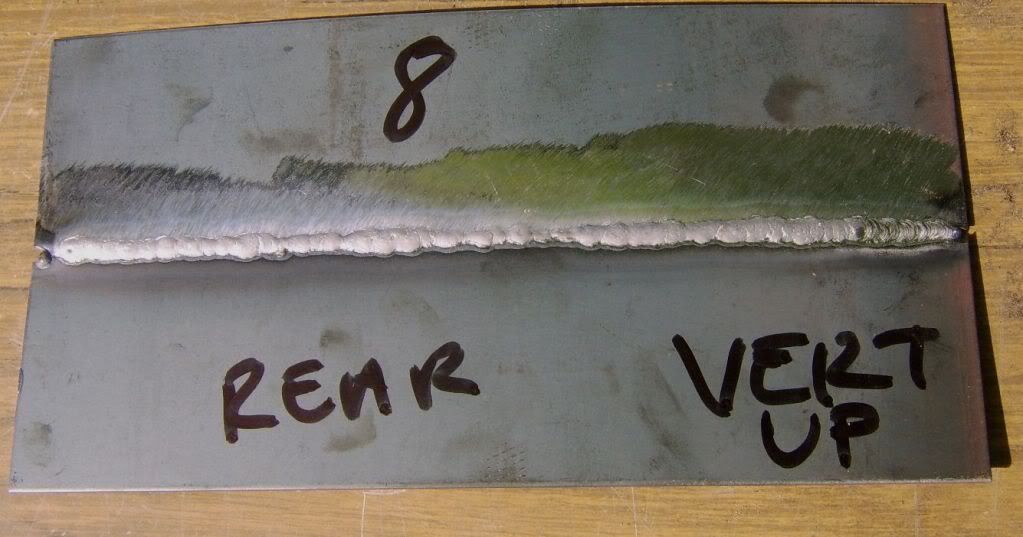

Weld 8. The welds were now, Vertical up butts. I was much better on these for some unfathomable reason ?

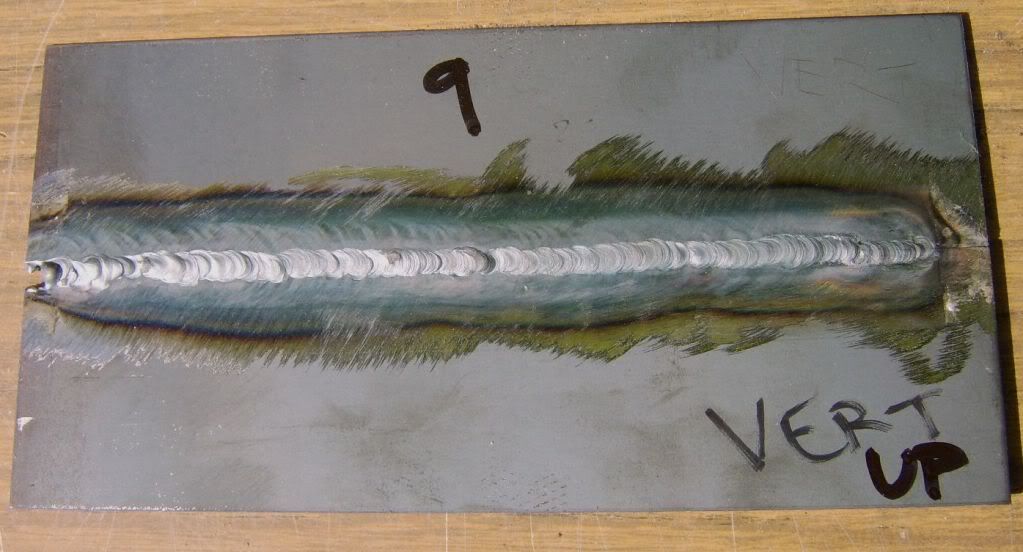

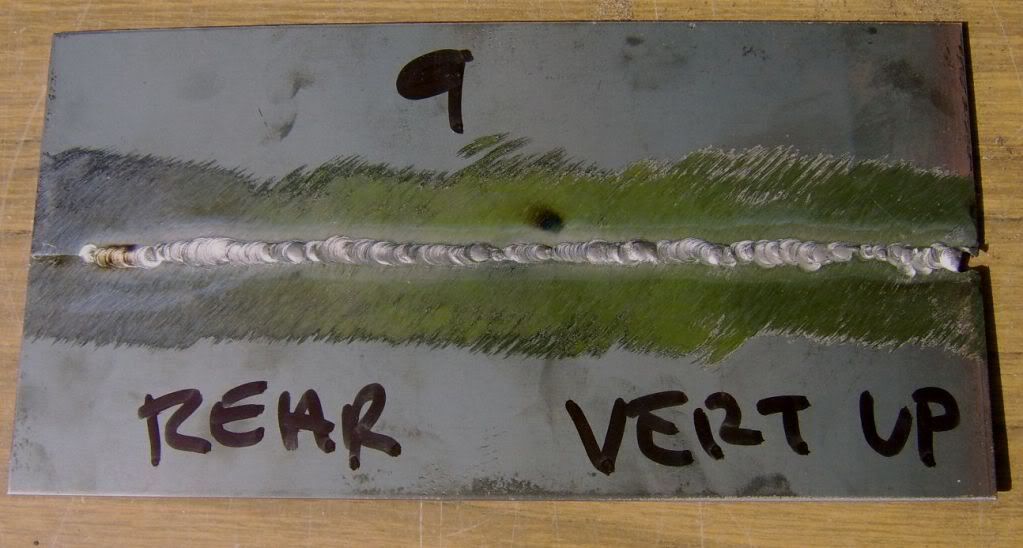

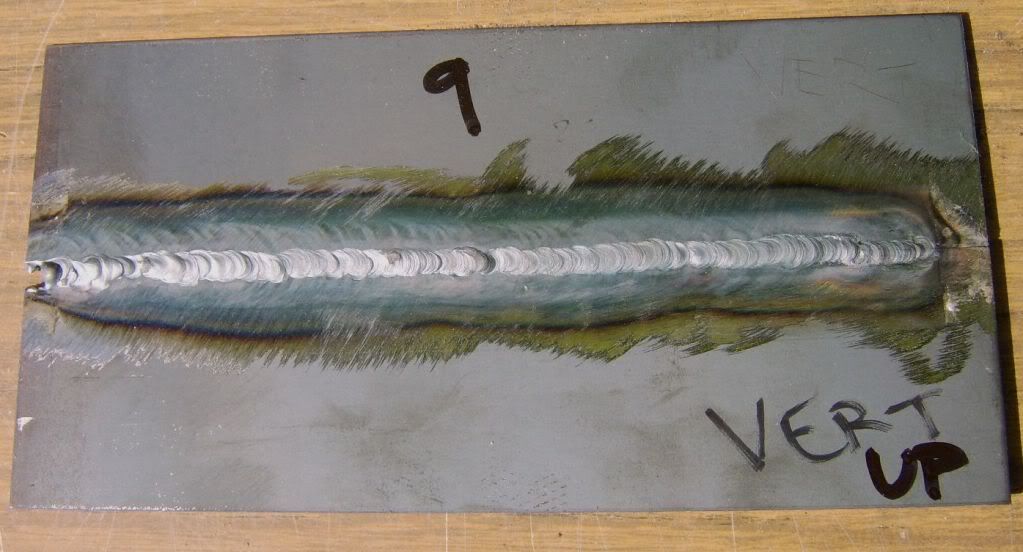

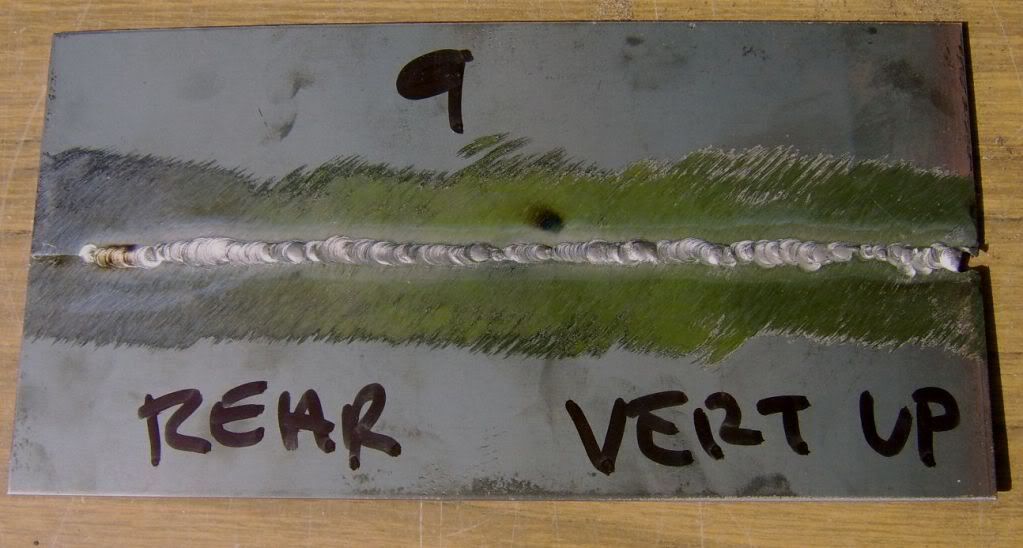

Weld 9 Again a small improvement.

---------------------------------------------------------------------------------------------

I have to do five weld pieces for the exam. So far i have done a flat butt, and a verticle butt. Both have passed the cupping test. I have also done a flat verticle lap weld. This is being sawn in half and tested next week. I will try and remember to photograph these for you to see, so anyone who is thinking of taking up the C&G TIG can see what is done. I will also continue to take pics untill the course is finished.

They are numbered 1 to 9. Over the period of 6 weeks I did them, these are a representation of my progress. The steel was 1.6mm plate. The flat welds had purge gas to rear, welded on a jig. The vertical welds had no purge and were just done clamped to a vice.

First here is the machine I do all my work on. A Miller synchcrowave 300

------------------------------------------------------------------------------------------------

Here is effort 1 front and back.Pretty rubbish and no penetration on the rear of weld.

Weld 2, slightly better weld but no penetration whatsoever, in other words worthless!

Weld 3, slightly better weld though a bit wobbly. penetration a bit better but still way off.

Weld 4 is a better less messy weld with again better pen to the rear. (This is what the tutor laughingly calls "A mechanics weld")

Weld 5, again a small improvement, but still a way to go.

Weld 6. By now i was getting well peed off. I could do a reasonable weld though I could not seem to get constant penetration all the way along.

Weld 7. Could it be true? I nearly had a good weld of an entire 8 inch run ?

Weld 8. The welds were now, Vertical up butts. I was much better on these for some unfathomable reason ?

Weld 9 Again a small improvement.

---------------------------------------------------------------------------------------------

I have to do five weld pieces for the exam. So far i have done a flat butt, and a verticle butt. Both have passed the cupping test. I have also done a flat verticle lap weld. This is being sawn in half and tested next week. I will try and remember to photograph these for you to see, so anyone who is thinking of taking up the C&G TIG can see what is done. I will also continue to take pics untill the course is finished.

Last edited by a moderator:

).

).

so will take my camera in next week again.

so will take my camera in next week again. We have a huge Meddings mechanical bandsaw for that sort of thing, takes about 10 seconds

We have a huge Meddings mechanical bandsaw for that sort of thing, takes about 10 seconds

give me a couple of years (or decades) and ill be at that level

give me a couple of years (or decades) and ill be at that level