You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Open circuit voltage vs voltage under load

- Thread starter Wozzaaah

- Start date

shenion

Tool Pack Rat

- Messages

- 7,586

- Location

- Stone Mountain, GA USA

Some machines have a higher OCV. My Lincoln had an OCV of about 50 volts. It required a load of about 5 amps for the regulator to work.

The bulbs go across the electrode/ground. They will effect the welding a bit.

That will give you approximately a 1 amp load, should be more than enough to bleed off the noise filter caps. If the unit has big output capacitors (usually the size of a soda can and several of them), then it would not have as much of an effect.

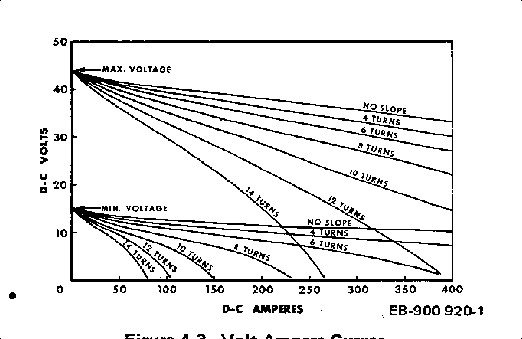

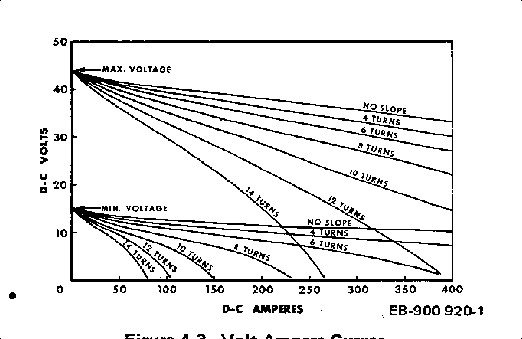

Like I said, there is an optimal slope. Spray transfer would want less. Here's the V/I curves from my Miller:

If I remember right, It was 4-6 turns for spray transfer and 10 for short arc. Although, the unit did not do short arc properly anyway. They fixed that in a later version and I modified it with a similar change (add a reactor.)

I added large caps to my Miller. The rectifier outputs a rectified AC signal. Under no load the caps will charge to the peak voltage (including noise on the line.) When welding, it drops to the RMS value; about 70% of the peak. Makes it useless to read the meter with no load. I go by the indicator on the setting dial anyway. I added the caps as it was a 3-phase machine and I was running it on single phase. The caps help maintain the arc between cycles (3 phase overlap so there is always voltage.)

The bulbs go across the electrode/ground. They will effect the welding a bit.

That will give you approximately a 1 amp load, should be more than enough to bleed off the noise filter caps. If the unit has big output capacitors (usually the size of a soda can and several of them), then it would not have as much of an effect.

Like I said, there is an optimal slope. Spray transfer would want less. Here's the V/I curves from my Miller:

If I remember right, It was 4-6 turns for spray transfer and 10 for short arc. Although, the unit did not do short arc properly anyway. They fixed that in a later version and I modified it with a similar change (add a reactor.)

I added large caps to my Miller. The rectifier outputs a rectified AC signal. Under no load the caps will charge to the peak voltage (including noise on the line.) When welding, it drops to the RMS value; about 70% of the peak. Makes it useless to read the meter with no load. I go by the indicator on the setting dial anyway. I added the caps as it was a 3-phase machine and I was running it on single phase. The caps help maintain the arc between cycles (3 phase overlap so there is always voltage.)

- Messages

- 6,329

I'd say your readout would be pretty useful, it will be telling you the readings under load which is what you want to know.

When you say it made no difference, to what, your readout or multimeter readings?

Really useful ermmm no, there of little use unless your into doing WPS work, even then a clamp type meter is needed for accuracy..... they just flicker around in the background severing little use the rest of the time

BTW wps "gestemate" is around a 1 Volt drop from machine parameters to actual welding volts........

an accepted method of setting an ARC voltage, is to know what the drop between OVC and arc volts are, deducting the latter from the first will of course give you an accurate arc voltage....hence the reason why OVC is used as to quote parimiters......

hmmmm I don't think load voltage (amps) has had a mention yet......

Last edited:

- Messages

- 17,292

Really useful ermmm no, there of little use unless your into doing WPS work, even then a clamp type meter is needed for accuracy..... they just flicker around in the background severing little use the rest of the time

BTW wps "gestemate" is around a 1 Volt drop from machine parameters to actual welding volts........

an accepted method of setting an ARC voltage, is to know what the drop between OVC and arc volts are, deducting the latter from the first will of course give you an accurate arc voltage....hence the reason why OVC is used as to quote parimiters......

hmmmm I don't think load voltage (amps) has had a mention yet......

Cor, this thread is turning into a

type of thread! So are my readings of any use Snowy or was it a fruitless exercise?

type of thread! So are my readings of any use Snowy or was it a fruitless exercise?Regarding amps, I'm not really concerned about that at the mo, just curious how my voltage readings tally up regarding setting my machine up for different welding scenarios.

This is starting to go way over my head

.

.- Messages

- 6,329

Cor, this thread is turning into atype of thread! So are my readings of any use Snowy or was it a fruitless exercise?

Regarding amps, I'm not really concerned about that at the mo, just curious how my voltage readings tally up regarding setting my machine up for different welding scenarios.

This is starting to go way over my head.

ermmm kinda wozzz the problem with them is I'm guessing you were on your Todd, so its hard to get accurate readings, but the to important figures are OVC and load voltage......

OVC is of course easily mesured, load voltage needs to be measured whilst running proper beads, (IE by someone else) the only true accurate way is to clamp between the contact tip and the weld pool, however of course this is not practical so on the swan neck some ware is accurate enouth....If your reading from DROs on the set a 1 volt drop is alowable...........

However to get a true reading wire speed (amps) must also be correct and the measurement should be over a period of time and read by someone else....

once you know the drop from OVC to LV you can then setting is a one man job of course, because a WPS will say x amount of volts....so you can dial up the correct OVC to allow for the LV.......make scense????

you can also do a between figure, set you wire speed (amps) then get someone to adjust the volts and read the meter, adjust the volts from the point when the wire stubs, to the point where the pool spreads, this will give you a given welding range, volts can then be set in the middle......and this will give you a tolerance allowing for changes in arc length, and torch angle.... which in the real world an operator can only ever achieve a range....

I cant see preloading a welder with light bulbs will ever give an accurate enough reading to stand up to the calls of procidure....

also none of this means squat, without including IPM of the wire feed, and wire size and type, as this is essentially responsible for (amps) and penetration, and lastly gas type......useing something like duel sheild flux core, essentially increases amps for the same dia, of wire..

Hope this helps have tried to keep it as simple and as brief as I can.....

- Messages

- 17,292

Good explanations Snowy, I think it's all getting a little too technical for my needs though, I'm never likely to get involved with WPSs so probably I'm 'going all round Bristol to get to Bath' as we say round here  .

.

What I'd liked to have done is compile a table of the load voltages, do some wire speed measurements then equate the results into an approximate amperage range, just for fun and for reference but I probably won't bother now, too many other variables to consider.

Thanks again for your valuable info

.

.What I'd liked to have done is compile a table of the load voltages, do some wire speed measurements then equate the results into an approximate amperage range, just for fun and for reference but I probably won't bother now, too many other variables to consider.

Thanks again for your valuable info

jugs

Dont wish to offend & annoy, but...

- Messages

- 1,449

Good explanations Snowy, I think it's all getting a little too technical for my needs though, I'm never likely to get involved with WPSs so probably I'm 'going all round Bristol to get to Bath' as we say round here.

What I'd liked to have done is compile a table of the load voltages, do some wire speed measurements then equate the results into an approximate amperage range, just for fun and for reference but I probably won't bother now, too many other variables to consider.

Thanks again for your valuable info

Could be usefull.

Don't any maufacter's have this kind of info ?

- Messages

- 17,292

Unfortunately not Jugs, the miller calculators give guidelines for certain types of joint on certain materials but it's up to the operator to know his/her machine and to set the parameters to suit. If you are a consistent welder who operates the same machine all day every day then it would become second nature to know what to set the controls at.

I'd just like to know accurately what voltage each step produces. Unfortunately like Snowy says, the only way to accurately measure it is under welding conditions so it's not easy. I did actually measure mine while welding but watching the multimeter while trying to maintain a consistent arc length and protect myself from the UV isn't easy at all.

I'd just like to know accurately what voltage each step produces. Unfortunately like Snowy says, the only way to accurately measure it is under welding conditions so it's not easy. I did actually measure mine while welding but watching the multimeter while trying to maintain a consistent arc length and protect myself from the UV isn't easy at all.

- Messages

- 6,329

Could be usefull.

Don't any maufacter's have this kind of info ?

TBH jugs its not possible for them to provide that data, ...... on 1 given set, I could be using 0.8mm, 1mm, 1.2mm solid wires or if its vertical or structural be welding with duel cored flux wires...... now as the IPM on the feed would vairy so essentially would the amps (think of wire speed as this)....... thats without taking into account my "skill" so thats my forward speed torch angle and stick out, again (amps/penetrtion)....... if I was to use a different length torch, couple miles of cable between the SWFU and the supply, and swap from heavy shield to Co2, the volts (heat) could change.....

so thats another Bristol via bath, way of saying, you can only really work your own variables out

jugs

Dont wish to offend & annoy, but...

- Messages

- 1,449

Unfortunately not Jugs, the miller calculators give guidelines for certain types of joint on certain materials but it's up to the operator to know his/her machine and to set the parameters to suit. If you are a consistent welder who operates the same machine all day every day then it would become second nature to know what to set the controls at.

I'd just like to know accurately what voltage each step produces. Unfortunately like Snowy says, the only way to accurately measure it is under welding conditions so it's not easy. I did actually measure mine while welding but watching the multimeter while trying to maintain a consistent arc length and protect myself from the UV isn't easy at all.

Unfortunately most of us aren’t, EG. I may only need to weld 1 hr/week then next MTh will weld for 2 days on a single setting

TBH jugs its not possible for them to provide that data, ...... on 1 given set, I could be using 0.8mm, 1mm, 1.2mm solid wires or if its vertical or structural be welding with duel cored flux wires...... now as the IPM on the feed would vairy so essentially would the amps (think of wire speed as this)....... thats without taking into account my "skill" so thats my forward speed torch angle and stick out, again (amps/penetrtion)....... if I was to use a different length torch, couple miles of cable between the SWFU and the supply, and swap from heavy shield to Co2, the volts (heat) could change.....

so thats another Bristol via bath, way of saying, you can only really work your own variables out

I can understand all the possible variables.

I suppose I was hoping for an improvement/addition to the excellent miller calc for dumbos like me

I suppose I was hoping for an improvement/addition to the excellent miller calc for dumbos like me

A table of basic initial settings of – volts, gasflow, wire speed, for each of the main joint types in a few common materials with some recommended variables for Vup, Vdown +OH. Based on 0.8mm in a “std hobby machine”, I think it could prove invaluable to us all.