You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

pipe

- Thread starter flange jockey

- Start date

flange jockey

Member

- Messages

- 173

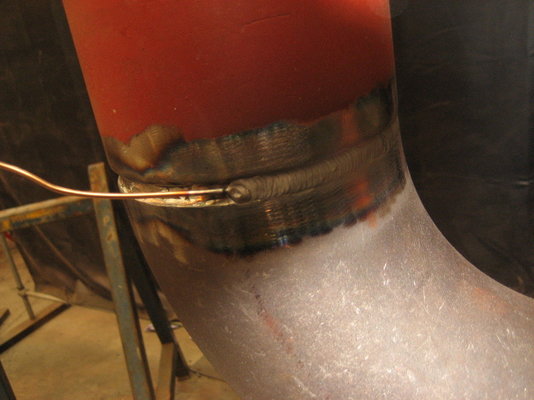

cheers alec, i mentioned gospel earlier, sorry for that, every now and again something crops up where a different approach is required, more of that later .[ treat these pics at least the first 3 as a what happened next, can you spot a weakness here, obviously the final responsibility lies with me. f/j

.[ treat these pics at least the first 3 as a what happened next, can you spot a weakness here, obviously the final responsibility lies with me. f/j

.[ treat these pics at least the first 3 as a what happened next, can you spot a weakness here, obviously the final responsibility lies with me. f/j

.[ treat these pics at least the first 3 as a what happened next, can you spot a weakness here, obviously the final responsibility lies with me. f/j

flange jockey

Member

- Messages

- 173

as you say jay, the prep is far too shallow , is that acute? the lad who did this and a number of setups is now my boss so i suppose its just right. the prob to myself and anyone who comes across this ,is drop the amps. i would normally and did here go for 120 amps rolling the second pass," i suppose the hot pass" . this is a term i am familiar with, yet on this occasion meant nothing.as the root went in at around 100 amps , i could have easily followed with 100 amps aware of the danger.f/j

the prob to myself and anyone who comes across this ,is drop the amps. i would normally and did here go for 120 amps rolling the second pass," i suppose the hot pass" . this is a term i am familiar with, yet on this occasion meant nothing.as the root went in at around 100 amps , i could have easily followed with 100 amps aware of the danger.f/j

the prob to myself and anyone who comes across this ,is drop the amps. i would normally and did here go for 120 amps rolling the second pass," i suppose the hot pass" . this is a term i am familiar with, yet on this occasion meant nothing.as the root went in at around 100 amps , i could have easily followed with 100 amps aware of the danger.f/j

the prob to myself and anyone who comes across this ,is drop the amps. i would normally and did here go for 120 amps rolling the second pass," i suppose the hot pass" . this is a term i am familiar with, yet on this occasion meant nothing.as the root went in at around 100 amps , i could have easily followed with 100 amps aware of the danger.f/jhi

great stuff but i notice you only cap your pipework in huge single runs, i do a lot of pipe welding and always weld multi cap runs, i just tested out again recently and did the usual 6g " carbon pipe and capped it off with 4 passes, i also did a 2" tig 5.5mm thick test and even that had a 2 run pass.

great stuff but i notice you only cap your pipework in huge single runs, i do a lot of pipe welding and always weld multi cap runs, i just tested out again recently and did the usual 6g " carbon pipe and capped it off with 4 passes, i also did a 2" tig 5.5mm thick test and even that had a 2 run pass.