gavuk

artful-bodger

- Messages

- 2,951

- Location

- Wilts

Most fab shops,steel stockists and engineering shops I've worked in or visited use bandsaws  .....I use a cold saw at work ,and prefer my cheapy bandsaw,we go through blades regulary,and have them sharpened on our cold saw...

.....I use a cold saw at work ,and prefer my cheapy bandsaw,we go through blades regulary,and have them sharpened on our cold saw...

Each to their own ,but for me 1.horizontal bandsaw

2.coldsaw

3.powerhacksaw

4.cut off tct

5.abrasive cut off

If we all agreed on everything ,we would all drive the same cars....

edit: we cut a lot of stainless at work on the cold saw

.....I use a cold saw at work ,and prefer my cheapy bandsaw,we go through blades regulary,and have them sharpened on our cold saw...

.....I use a cold saw at work ,and prefer my cheapy bandsaw,we go through blades regulary,and have them sharpened on our cold saw...Each to their own ,but for me 1.horizontal bandsaw

2.coldsaw

3.powerhacksaw

4.cut off tct

5.abrasive cut off

If we all agreed on everything ,we would all drive the same cars....

edit: we cut a lot of stainless at work on the cold saw

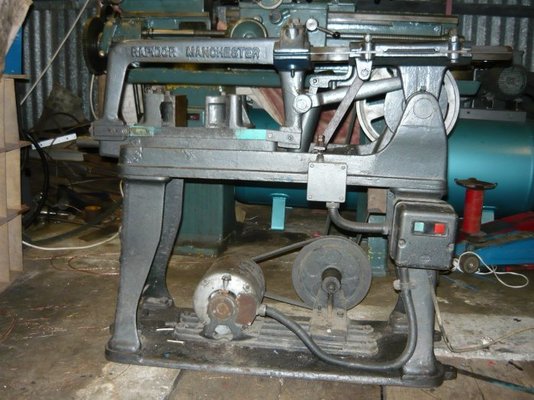

if you find them let me know and I'll drop by when I pass your way. I will strip her down, she's pretty grimey but it seems complete and the damper works and vice seems OK but I've only managed to drag her out of the back onto a pair of trestles so far.

if you find them let me know and I'll drop by when I pass your way. I will strip her down, she's pretty grimey but it seems complete and the damper works and vice seems OK but I've only managed to drag her out of the back onto a pair of trestles so far.