Pigeon_Droppings2

Member

- Messages

- 6,641

- Location

- london

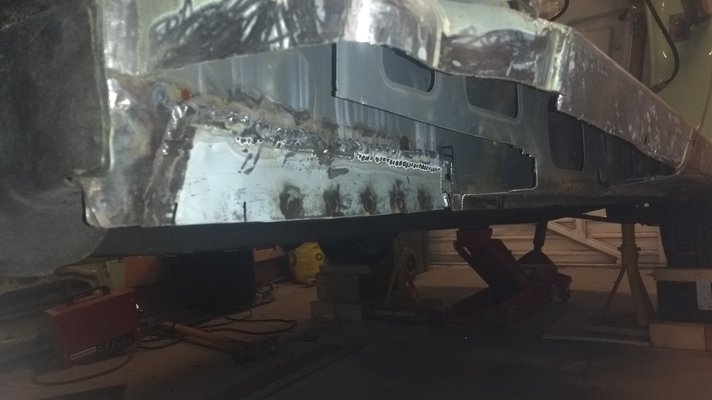

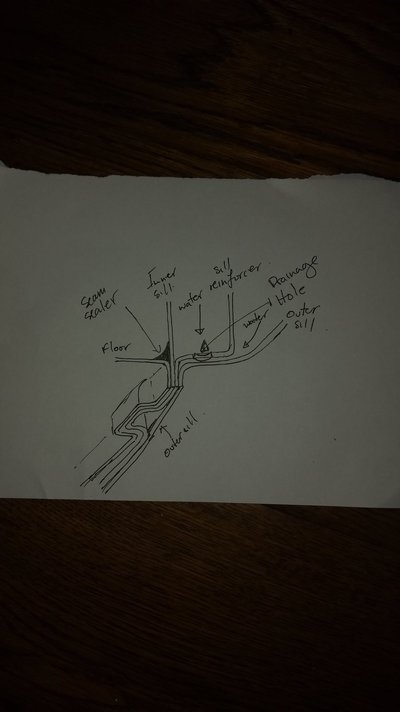

Managed to get a bit more done on the inner sill. All seemed to go quite well...I joggled the horizontal joint at the top and welded it from both sides then did just a few spots at the bottom. The joggle is on the inside of the sill so it'll be hidden once the repairs are complete...this made the welding a little easier for me as a joggle joint is more forgiving in terms of getting the repair patch made plus there isn't a lot of room to easily run an angle grinder along to gap a butt weld. I'm not really looking forward to putting the reinforcement back on the outside of the inner sill as it needs to be aligned carefully so that the outer sill end can fit back on. The sill end is curved so that's going to be fun for another day plus the reinforcement slopes upwards to the sill end....gulp!

I put some etch primer on the floor as it may be a while until I get to work on the car....the welds have been flatted to take the tops off but I haven't ground them flush....this area will be covered in sound proofing anyway so better to leave the welds a little proud and avoid thinning the metal.

I put some etch primer on the floor as it may be a while until I get to work on the car....the welds have been flatted to take the tops off but I haven't ground them flush....this area will be covered in sound proofing anyway so better to leave the welds a little proud and avoid thinning the metal.