RaceDiagnostics

Forum Supporter

- Messages

- 3,186

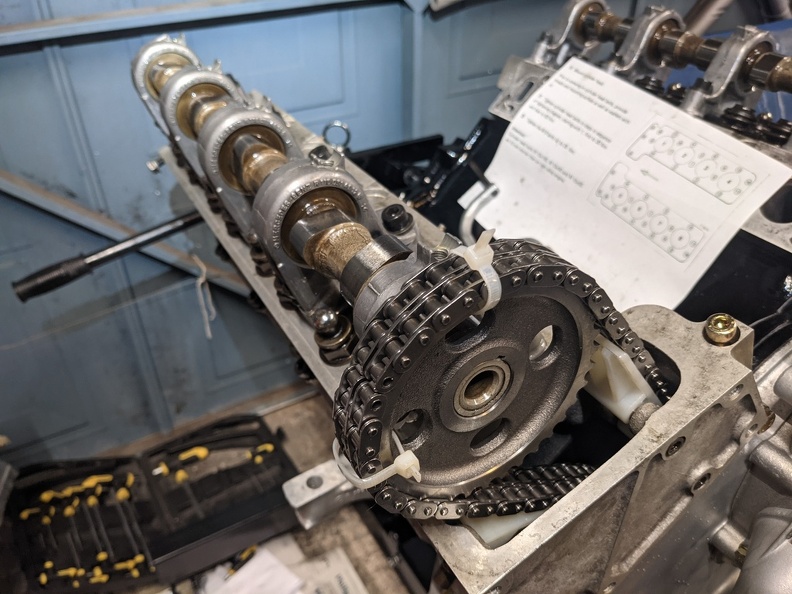

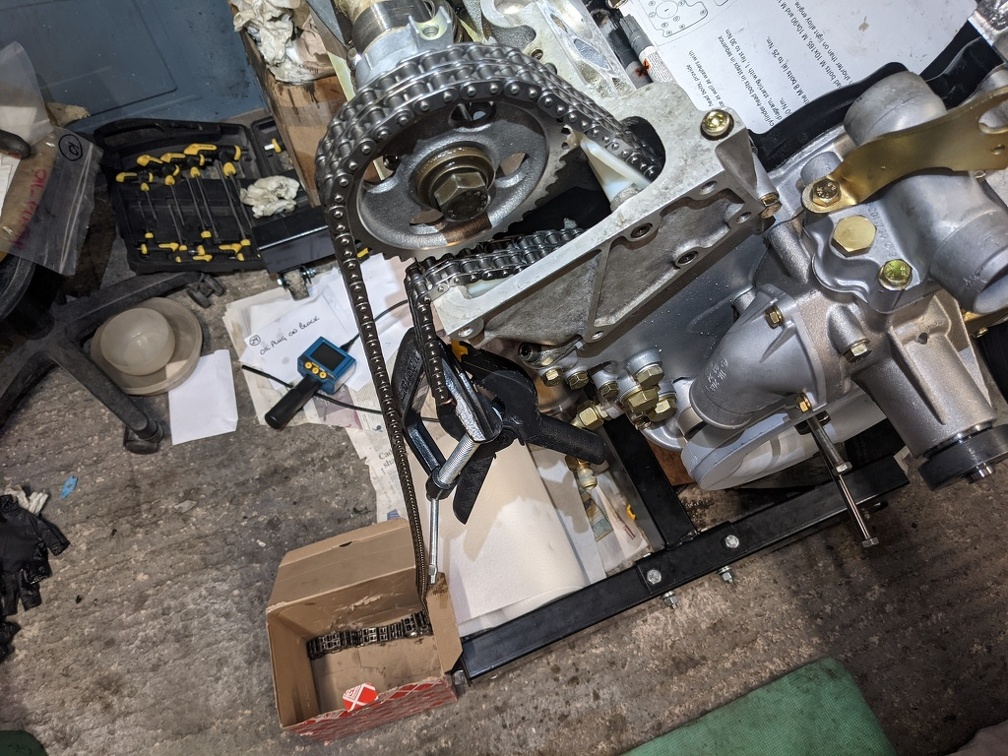

Killing time this morning before heading to the machine shop to pick up the CAMs.

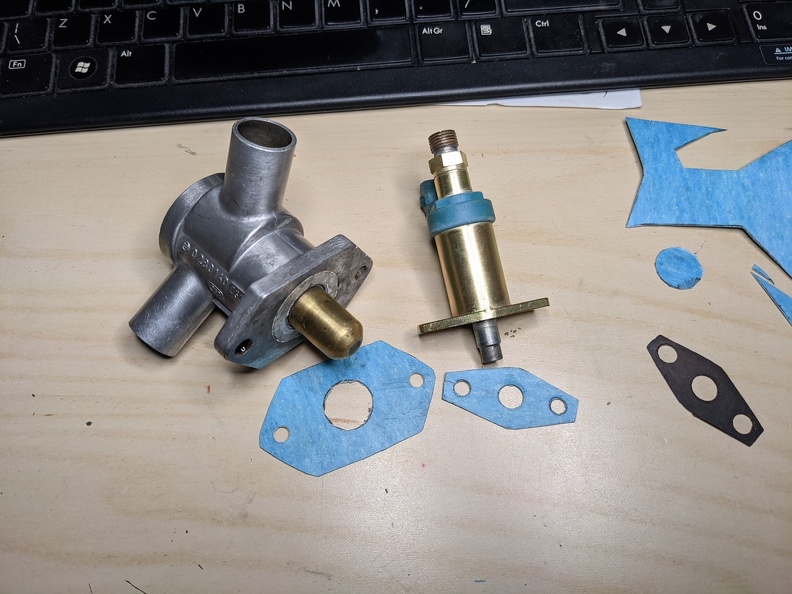

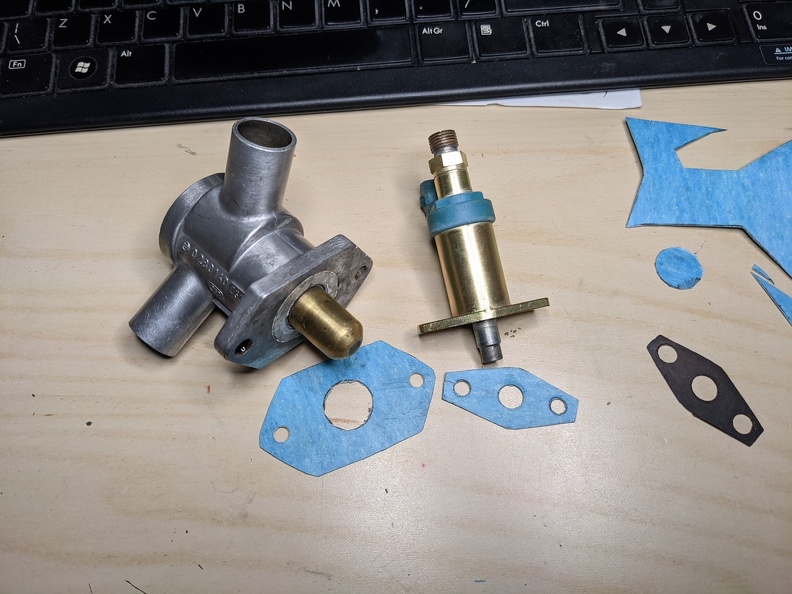

Starter motor and solenoid bolted back together.

Need to sort out a couple of new screws there.

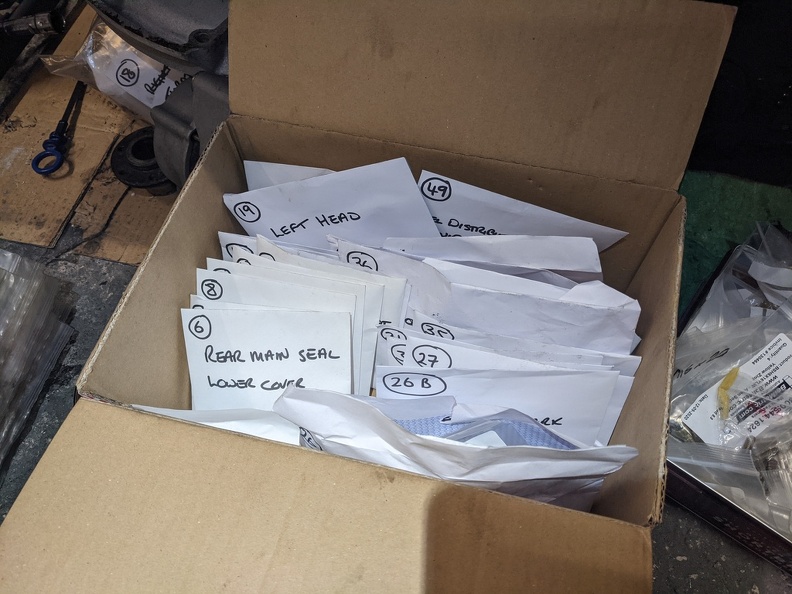

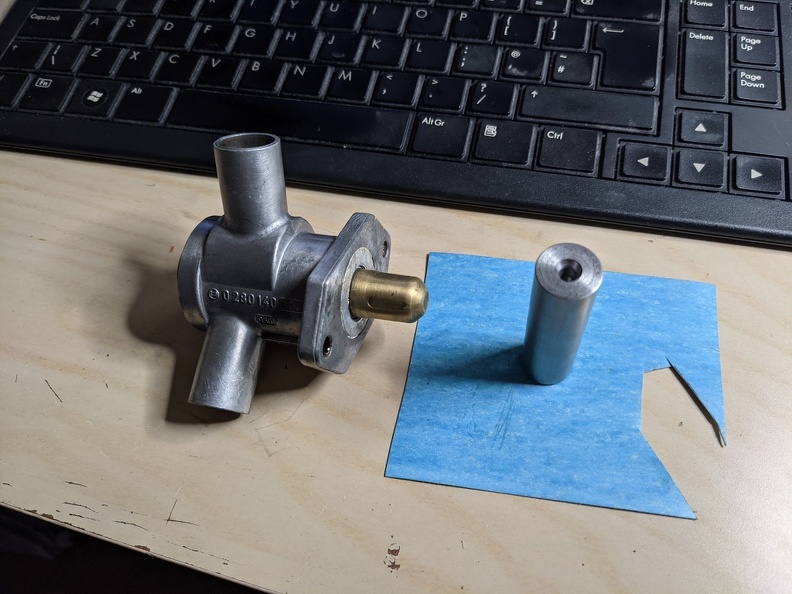

The full engine rebuild gasket set wasn't as full as it could have been, so cut out a couple of new gaskets.

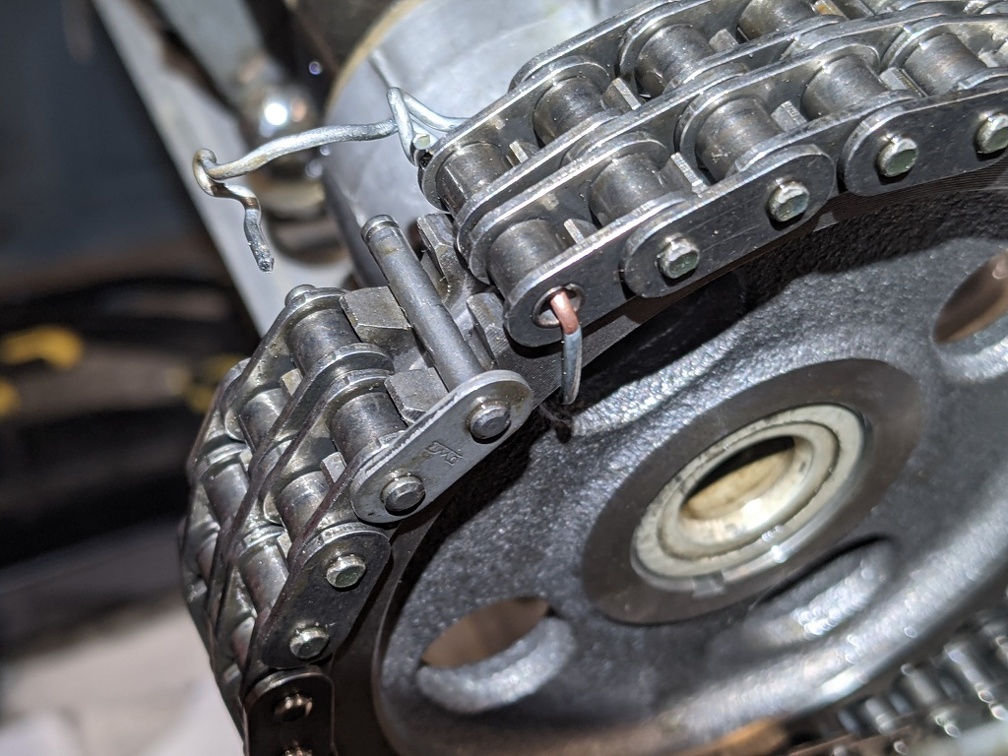

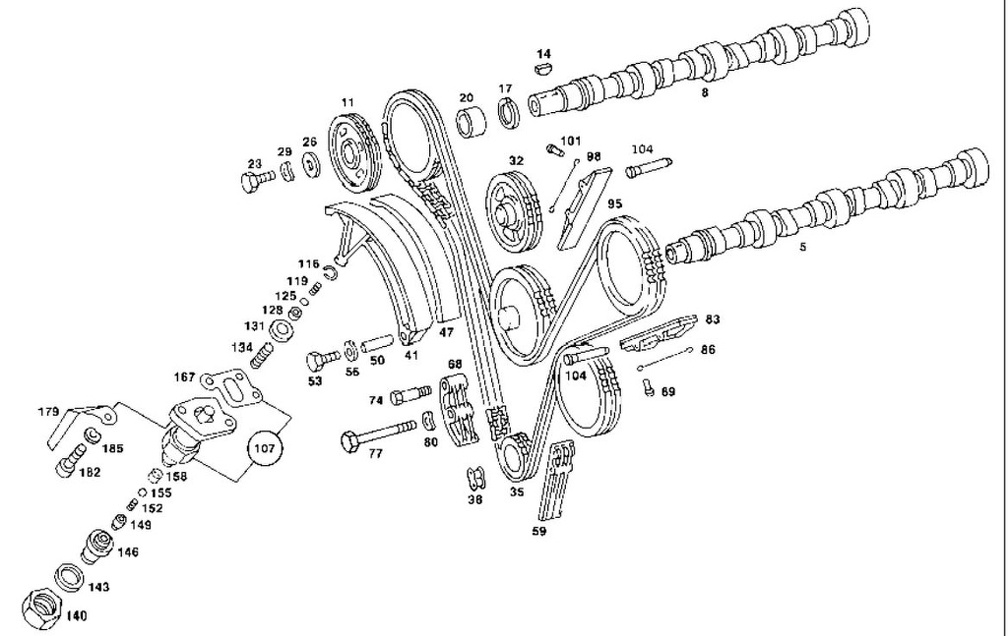

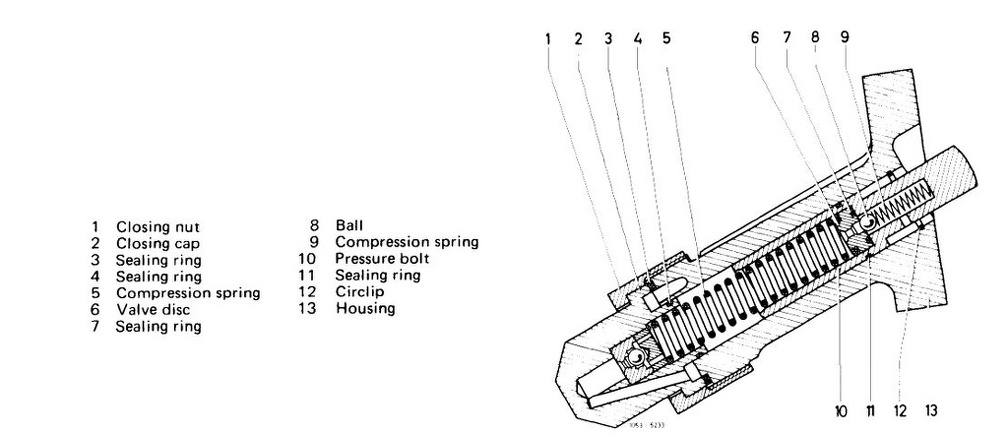

Oil pump damper back together.

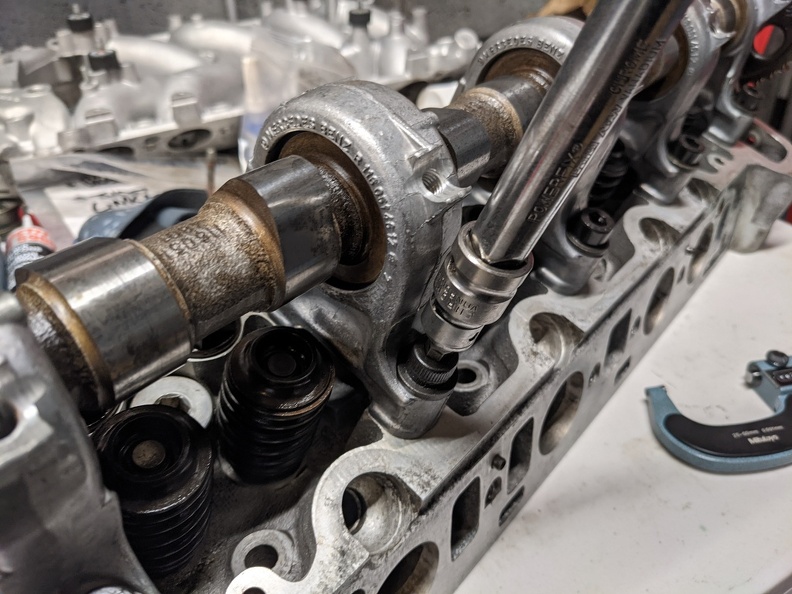

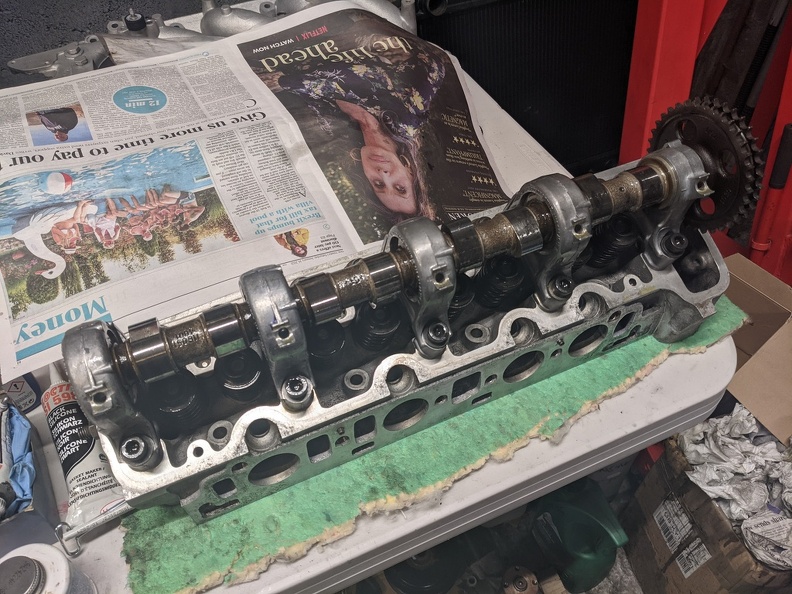

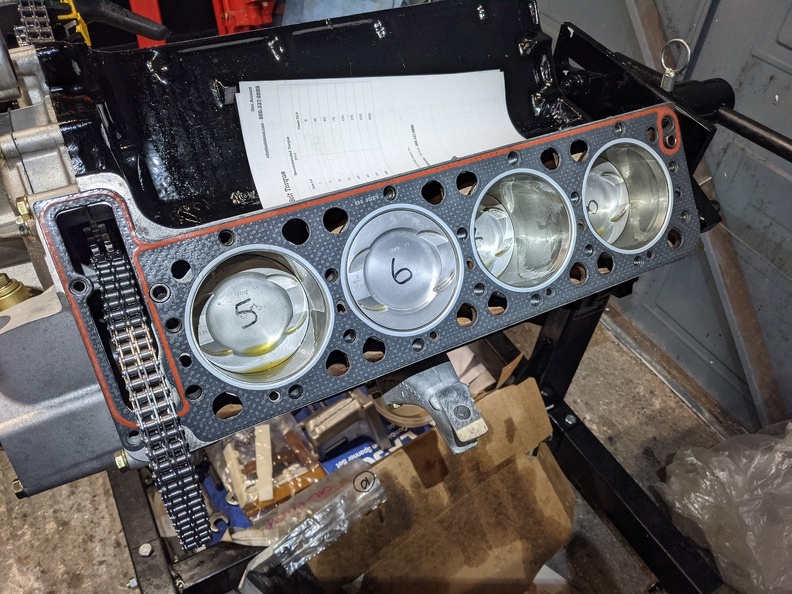

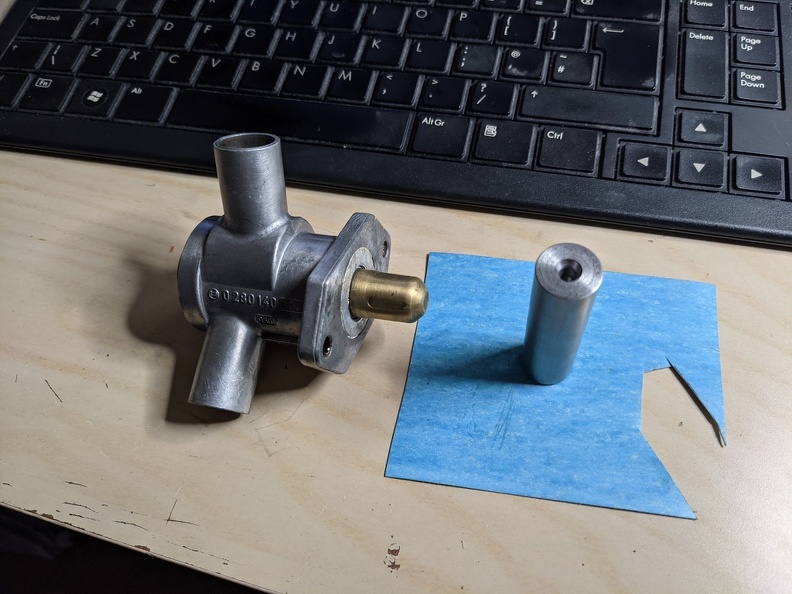

Then off to pick up the CAMs. The left CAM perfectly on the target size. And rotates perfectly with all the cam towers bolted down.

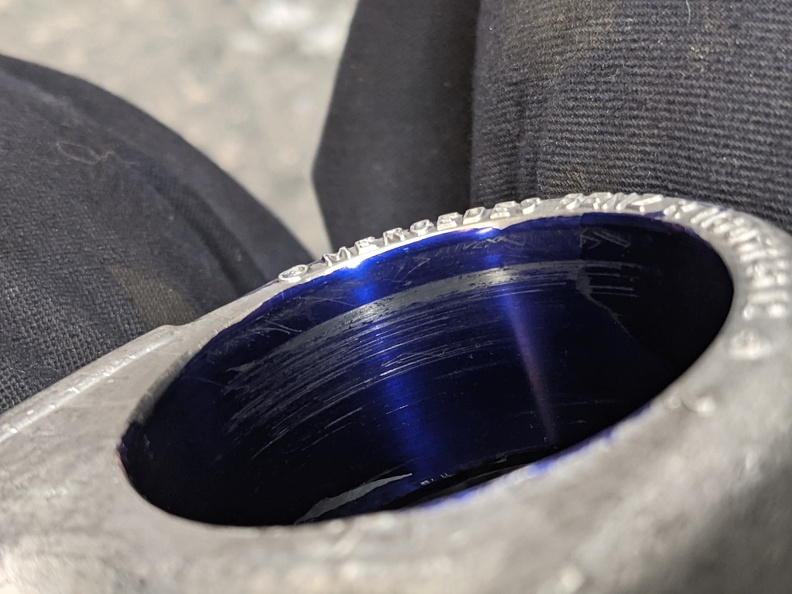

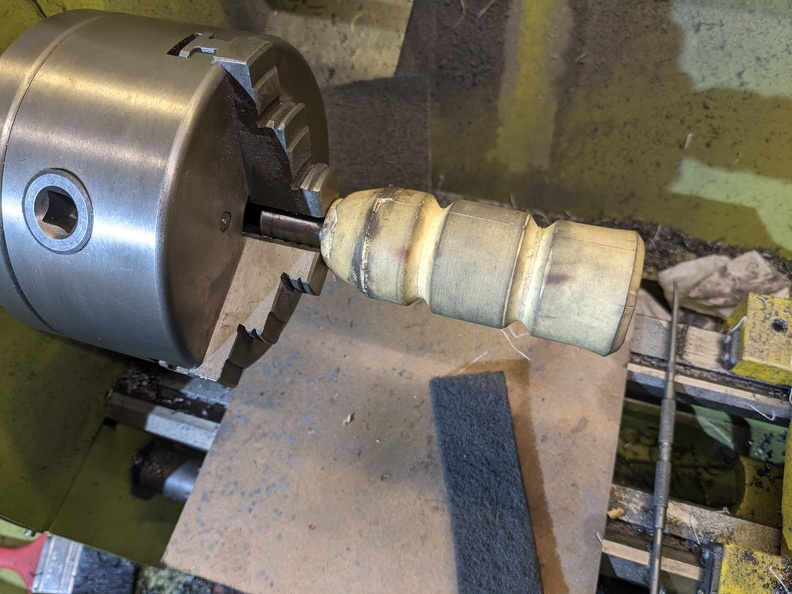

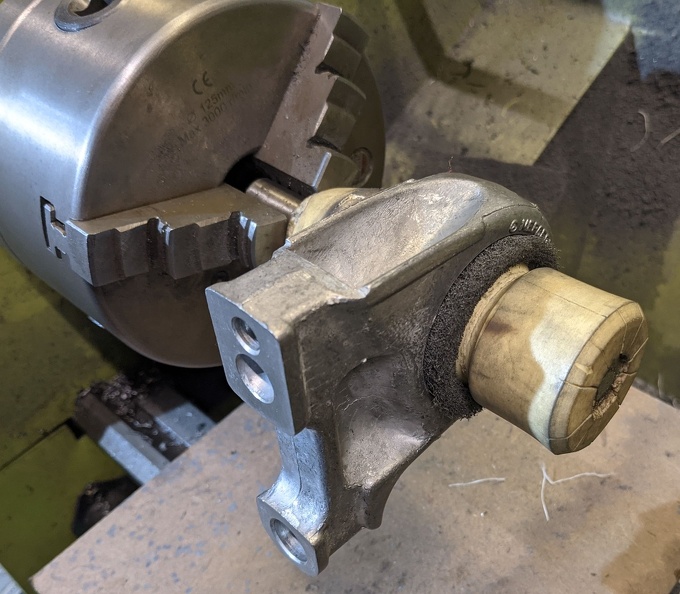

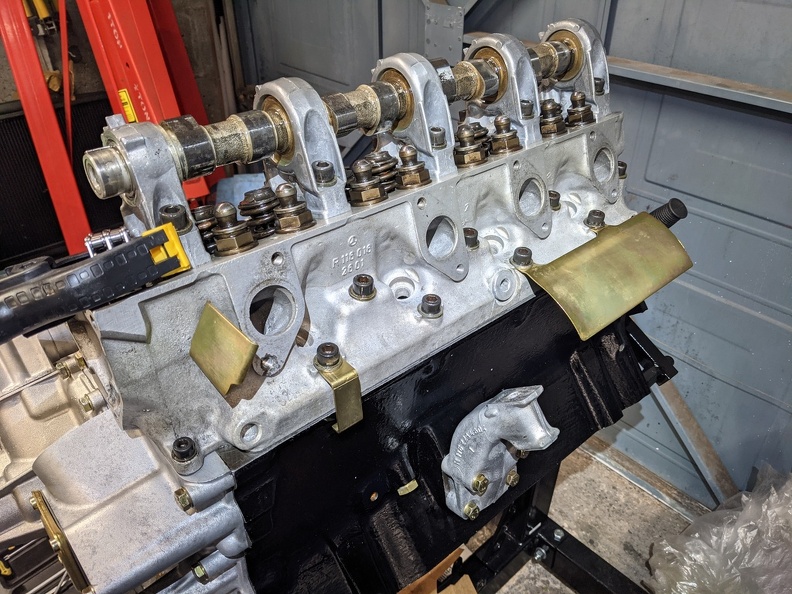

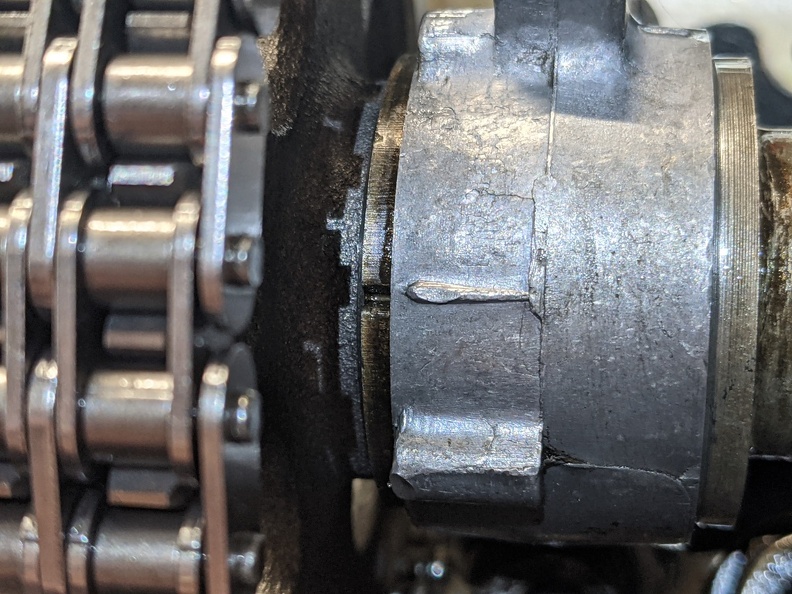

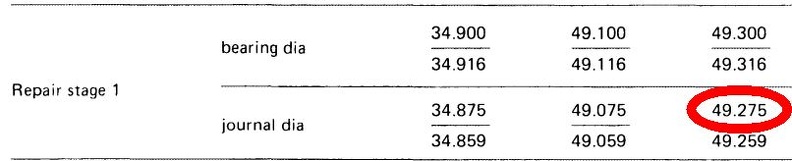

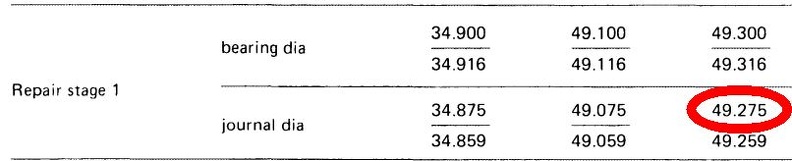

The right CAM is not so good news, it has had the leftmost two journals ground (1 and 2). The far left is perfectly on size at 49.275 but the next one in is oversize at 49.28, however even with that there should still be a bit of clearance if everything was concentric. When I tighten down tower 2 (with the others already tightened down) the CAM shaft binds up (worked it out through a process of elimination). It's no big deal and I am sure the machine shop will be able to sort it out, but they are now closed till next Monday so I will have a bit of a delay.

Starter motor and solenoid bolted back together.

Need to sort out a couple of new screws there.

The full engine rebuild gasket set wasn't as full as it could have been, so cut out a couple of new gaskets.

Oil pump damper back together.

Then off to pick up the CAMs. The left CAM perfectly on the target size. And rotates perfectly with all the cam towers bolted down.

The right CAM is not so good news, it has had the leftmost two journals ground (1 and 2). The far left is perfectly on size at 49.275 but the next one in is oversize at 49.28, however even with that there should still be a bit of clearance if everything was concentric. When I tighten down tower 2 (with the others already tightened down) the CAM shaft binds up (worked it out through a process of elimination). It's no big deal and I am sure the machine shop will be able to sort it out, but they are now closed till next Monday so I will have a bit of a delay.