a little over 5 years of use and Ive finally got round to modifying one of my toolholders so it is easier to hold 1/8" square hss blanks. rather than modifying a blank one, I thought I could modify one end of a long reach one. I decided that I wanted the toolbits to be clamped in place rather than being held by screws/bolts.

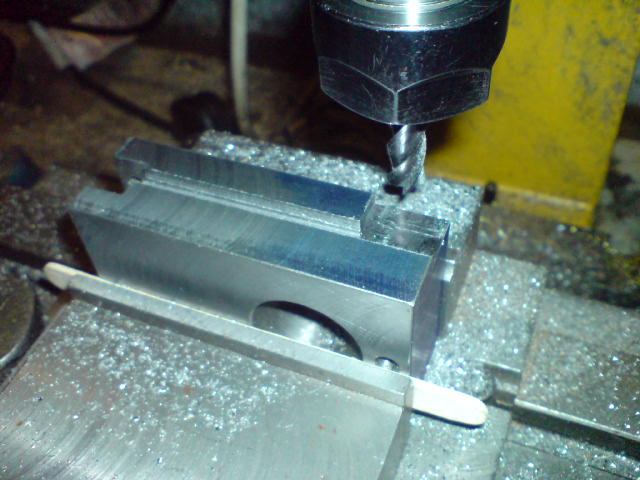

first it was necessary to mill a slot along the length of the toolholder for the tool to go in and some clearance for the clamp that holds the tool in place

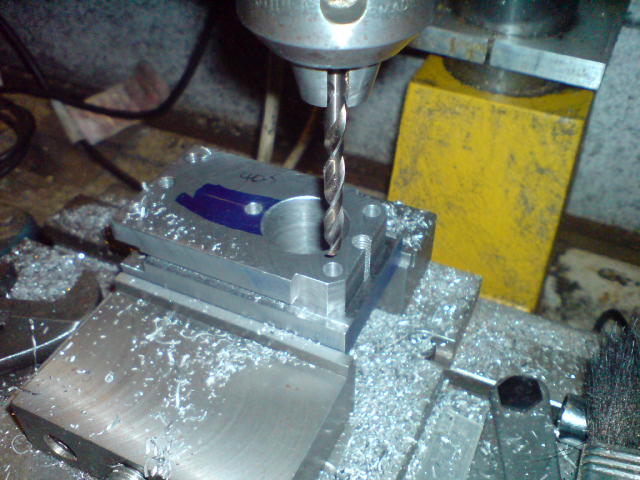

the back of the toolholder had some clearance milled too

and screws redrilled and tapped

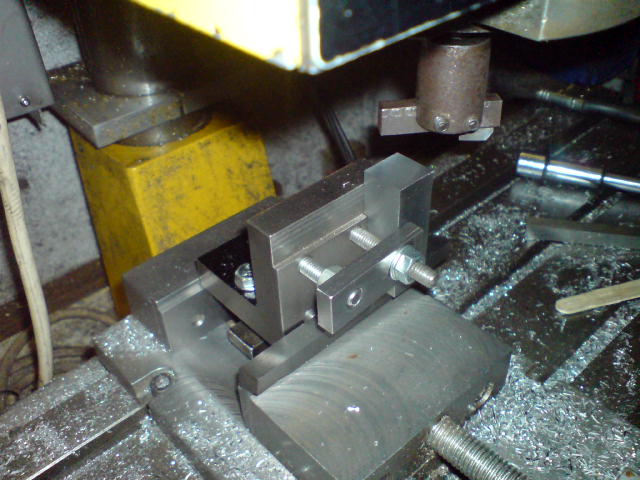

then the tool clamp needed to be made. I do like the finish of flycutter, and Im squaring up the end face of it here. the angle plate in the vice has vertical and horizontal rebates milled into it, so I dont have to bother clocking them up now.

the inside cavity of the clamp was then milled out.

and then the recess for the tool post was bored in the lathe, clamping 4mm drills in the slot to give clearance to the toolholder body.

and the finished parts

and in use with a 0.9mm wide grooving bit, now its less fiddly to set up than trying to use a tool holder designed for 8mm tool blanks.

first it was necessary to mill a slot along the length of the toolholder for the tool to go in and some clearance for the clamp that holds the tool in place

the back of the toolholder had some clearance milled too

and screws redrilled and tapped

then the tool clamp needed to be made. I do like the finish of flycutter, and Im squaring up the end face of it here. the angle plate in the vice has vertical and horizontal rebates milled into it, so I dont have to bother clocking them up now.

the inside cavity of the clamp was then milled out.

and then the recess for the tool post was bored in the lathe, clamping 4mm drills in the slot to give clearance to the toolholder body.

and the finished parts

and in use with a 0.9mm wide grooving bit, now its less fiddly to set up than trying to use a tool holder designed for 8mm tool blanks.