Fred Trevvett

Member

- Messages

- 377

- Location

- Harrogate UK

Hello,

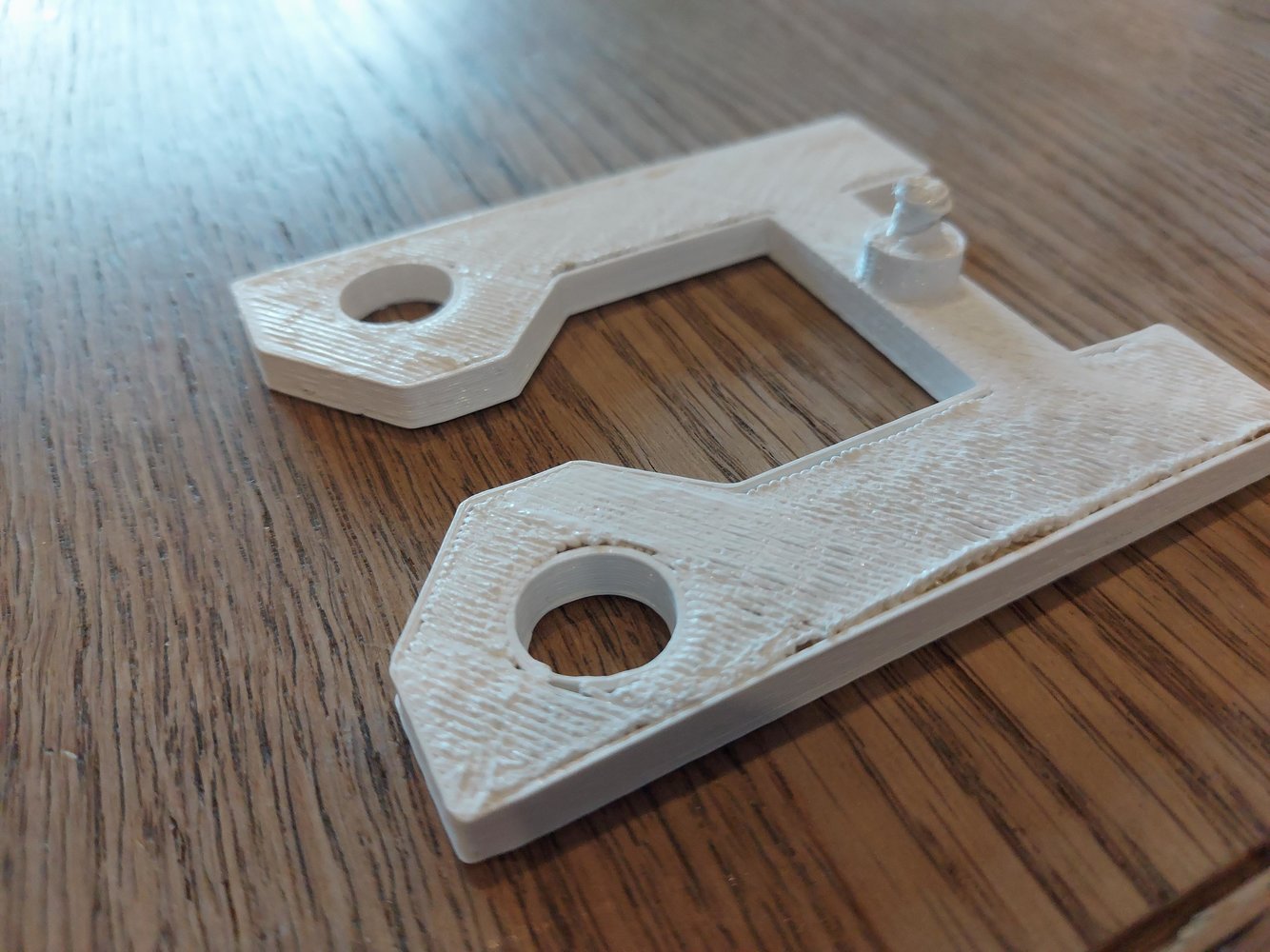

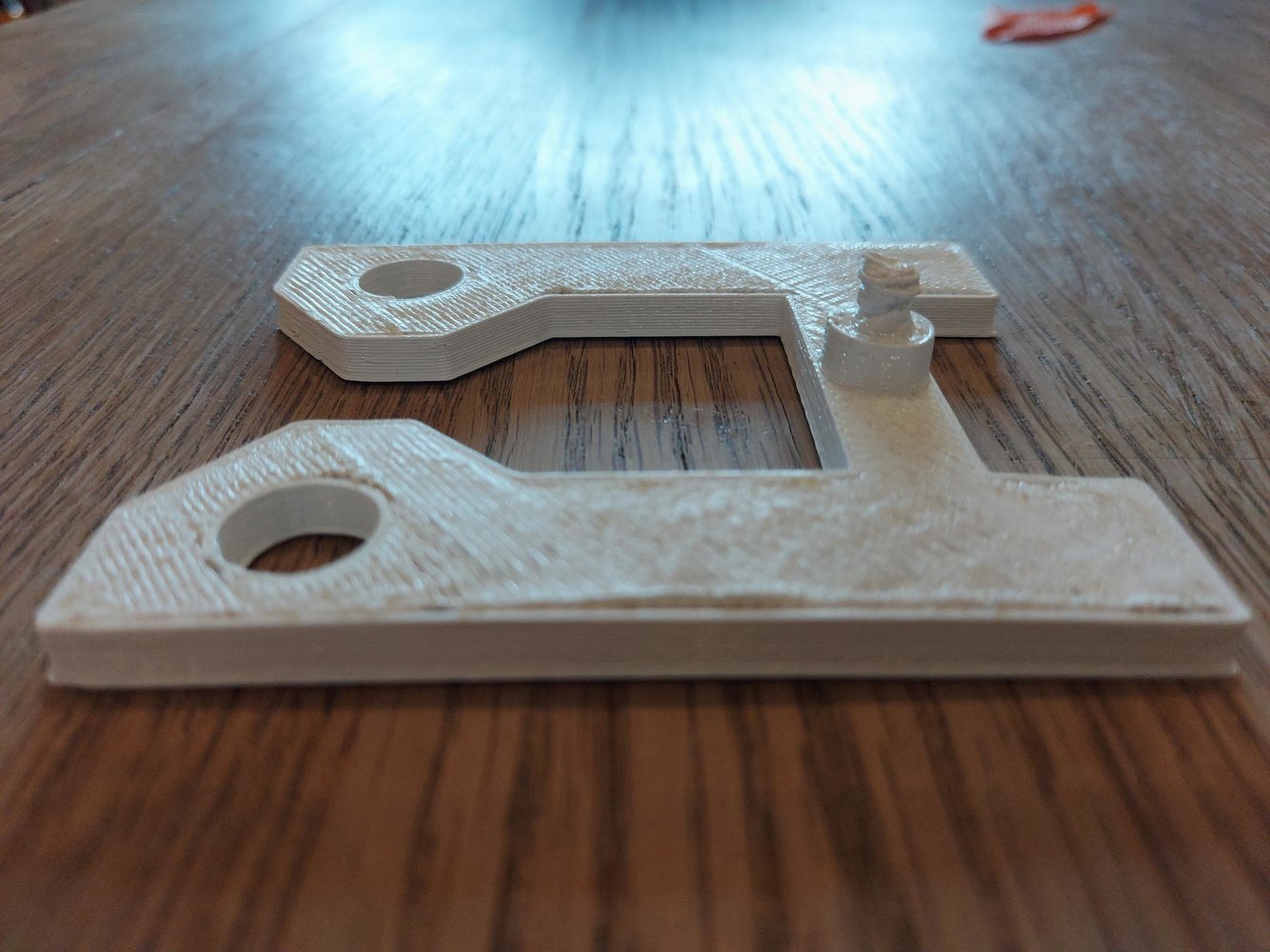

Picked up a XYZ Da Vinci 1.0 last night and have been tinkering with it today. I'm not entirely happy with the quality of the prints, and I know you are never going to get as good a surface finish as something that's been moulded, but I hope the collective can offer advice on how to improve things (hopefully without too many conflicting opinions)

Main issues:

Top of print not being closed off properly - amost like the infill 'web' comes through to the surface

Pin not printing well - should be cylindrical

Minor details:

Non round holes - I know they are never going to be perfect, and yes I can print undersize then drill out to size, but is this really as good as they can be?

For context, this part is about 75mm long. I can send the stl file if anyone wants to do some tinkering, or just let me know what settings to tweak and I will reprint however many times it's needed

Picked up a XYZ Da Vinci 1.0 last night and have been tinkering with it today. I'm not entirely happy with the quality of the prints, and I know you are never going to get as good a surface finish as something that's been moulded, but I hope the collective can offer advice on how to improve things (hopefully without too many conflicting opinions)

Main issues:

Top of print not being closed off properly - amost like the infill 'web' comes through to the surface

Pin not printing well - should be cylindrical

Minor details:

Non round holes - I know they are never going to be perfect, and yes I can print undersize then drill out to size, but is this really as good as they can be?

For context, this part is about 75mm long. I can send the stl file if anyone wants to do some tinkering, or just let me know what settings to tweak and I will reprint however many times it's needed