stewart.d.campbell

Member

- Messages

- 126

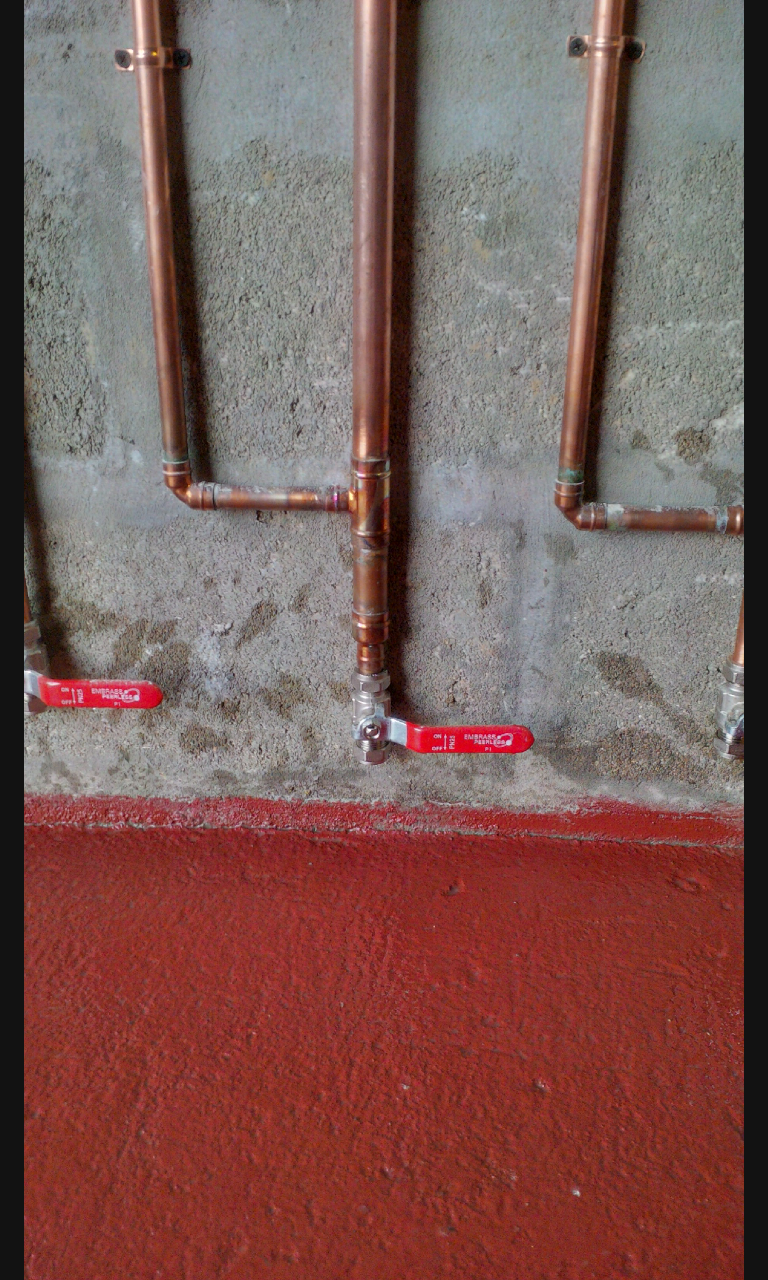

Got this finished up, put one leg of 22mm in and mounted it directly to the cold wall.Filter i bought had no o rings between the yoke and the body when i got it which the seller neglected to tell me.

Nice idea, just one questionIs there any need for four drain valves and could they not all linked together with the one drain point

Bob

Run some water through it?

try it in summer using a lot of airGave this some use today and seems to be working well, no moisture in the inline filter at the gun, less water at each ball valve on the cooler and hardly any in the filter regulator on the wall.

try it in summer using a lot of air

. There are ways of doing it right and let's not forget water / moisture is only the first thing. Those of us that do more of this blasting thing, know, we try to advise and help. I am not saying that it can't work, what I am saying is that it has limitations

. There are ways of doing it right and let's not forget water / moisture is only the first thing. Those of us that do more of this blasting thing, know, we try to advise and help. I am not saying that it can't work, what I am saying is that it has limitations

Thats the thing, it probably wont get a lot of use so it isnt worth going much further than knocking up a cheap solution.Mt two cents worth. Again depending on the amount of usage. People seem to think they can whip up some pipe , put it on the wall or in a bucket of cold water and no more moisture in the air lines. If you have a serious job (that also varies from person to person what is a serious job) to do, along with the environmental conditions (temperature and humidity) all these 'fixes' will leave you lacking. You can also, talk yourself into anything (famous Australian saying) 'she'll be right mate' springs to mind. There are ways of doing it right and let's not forget water / moisture is only the first thing. Those of us that do more of this blasting thing, know, we try to advise and help. I am not saying that it can't work, what I am saying is that it has limitations