You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SIP / Cosmo Wire Feed Solution

- Thread starter darrencambs

- Start date

justgeorge

New Member

- Messages

- 5

- Location

- australias north

Cheers for the solution. Here's an alternate:

http://www.mig-welding.co.uk/forum/threads/sip-wire-feed-solution-number-2.44924/

http://www.mig-welding.co.uk/forum/threads/sip-wire-feed-solution-number-2.44924/

Hi all,

I've been registered on this forum for a while now, but have been lurking quietly in the background most of the time! Great site by the way - amazing how much I've managed to learn from here.

Unfortunately, I discovered this forum after I'd purchased a Cosmo welder - probably would have gone for a different machine if I'd have known about the bad reputation SIP / Cosmo have

Anyway, I have run about half a dozen small reels through it over the last few months without any problems. Then within a couple of days of putting in a large reel, I started to experience problems with the wire feed.

The motor was turning, but the rollers were slipping and not feeding the wire through.

On closer inspection, I could see that the plastic pivot that carriers the idler roller was flexing. This resulted in the rollers being out of true, and losing the grip on the wire.

I came up with a simple solution that stops this from happening. So far, I've run another large reel through without any problems at all - wire feed is much more stable and no signs of slipping.

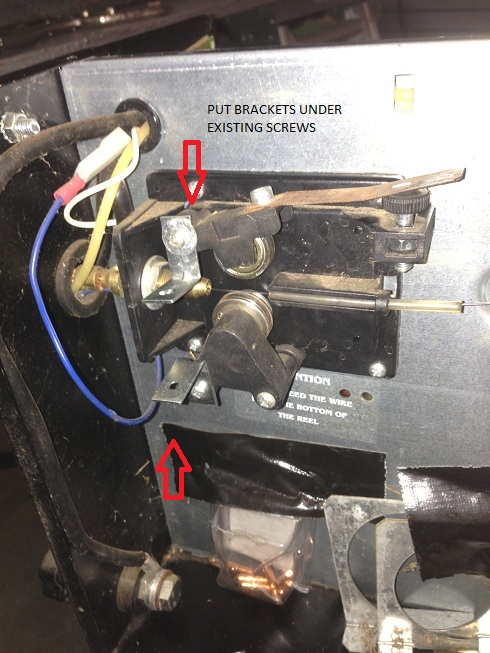

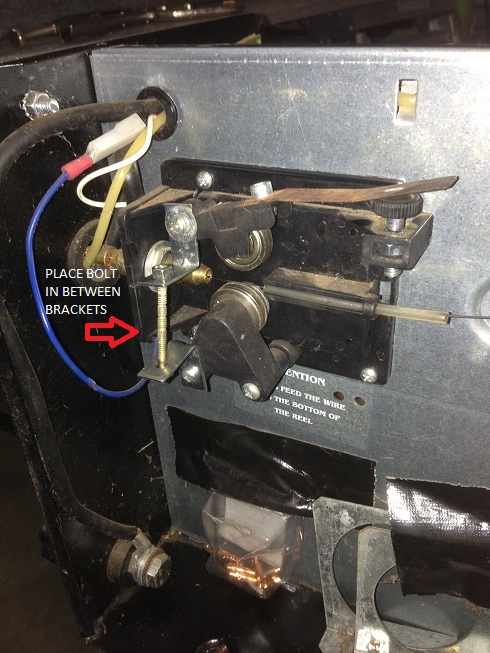

A couple of photos below to show the simple solution. Hopefully this will be of use to anyone who's suffering these sort of problems with their SIP / Cosmo machine. Probably worth trying before changing to a steel liner?

View attachment 1938

Hi all,

I've been registered on this forum for a while now, but have been lurking quietly in the background most of the time! Great site by the way - amazing how much I've managed to learn from here.

Unfortunately, I discovered this forum after I'd purchased a Cosmo welder - probably would have gone for a different machine if I'd have known about the bad reputation SIP / Cosmo have

Anyway, I have run about half a dozen small reels through it over the last few months without any problems. Then within a couple of days of putting in a large reel, I started to experience problems with the wire feed.

The motor was turning, but the rollers were slipping and not feeding the wire through.

On closer inspection, I could see that the plastic pivot that carriers the idler roller was flexing. This resulted in the rollers being out of true, and losing the grip on the wire.

I came up with a simple solution that stops this from happening. So far, I've run another large reel through without any problems at all - wire feed is much more stable and no signs of slipping.

A couple of photos below to show the simple solution. Hopefully this will be of use to anyone who's suffering these sort of problems with their SIP / Cosmo machine. Probably worth trying before changing to a steel liner?

View attachment 1938

altho i havent done any of these mods.the steel strap on the rollers an moveing the wire roller up an inch..i also have made a mod...bought a proper argon regulator an found a part on ebay to change the small throaway argon bottle to a larger reusaable bottle.will put pics up latter today..

wacky7791

Member

- Messages

- 224

- Location

- SEQ australia

Hi all sure your all bored of the old SIP questions on wirefeed mods so i'll make it quick, was gonna do a seperate PSU mod but the wire feed curcuit board on my migmate 150 looks to have a transformer built in, have SIP learnt a lesson here or do I still need to run the mod?

Has a metal liner and just done the feedwheel strap mod.

Cheers

Has a metal liner and just done the feedwheel strap mod.

Cheers

cumbriasteve

Moderator

- Messages

- 9,645

- Location

- Cumbria UK

Welcome to the forumHi all sure your all bored of the old SIP questions on wirefeed mods so i'll make it quick, was gonna do a seperate PSU mod but the wire feed curcuit board on my migmate 150 looks to have a transformer built in, have SIP learnt a lesson here or do I still need to run the mod?

Has a metal liner and just done the feedwheel strap mod.

Cheers

, answers may be slow because you have added into an existing thread but am sure someone with the knowledge will see your post soon, if not then start again in the introduction section

, answers may be slow because you have added into an existing thread but am sure someone with the knowledge will see your post soon, if not then start again in the introduction sectionHi all,

I've been registered on this forum for a while now, but have been lurking quietly in the background most of the time! Great site by the way - amazing how much I've managed to learn from here.

Unfortunately, I discovered this forum after I'd purchased a Cosmo welder - probably would have gone for a different machine if I'd have known about the bad reputation SIP / Cosmo have

Anyway, I have run about half a dozen small reels through it over the last few months without any problems. Then within a couple of days of putting in a large reel, I started to experience problems with the wire feed.

The motor was turning, but the rollers were slipping and not feeding the wire through.

On closer inspection, I could see that the plastic pivot that carriers the idler roller was flexing. This resulted in the rollers being out of true, and losing the grip on the wire.

I came up with a simple solution that stops this from happening. So far, I've run another large reel through without any problems at all - wire feed is much more stable and no signs of slipping.

A couple of photos below to show the simple solution. Hopefully this will be of use to anyone who's suffering these sort of problems with their SIP / Cosmo machine. Probably worth trying before changing to a steel liner?

View attachment 1938

Genius. I had an unused machine that had been sitting for 10 years, with the bit of plastic loaded up. Terrible feed problems, was ready to throw it out. I could see top roller pin was a weak point and contemplated trying to put in a proper wire feeder, but thought it was not worth the effort . I think your genius lies not so much in identifying the problem or solving it, but solving it so simply. Saw your solution, 5 minutes to make and works perfectly. I did one further "mod", when the top roller was out, i bent the plastic pin gently closer to vertical, and hit it for a second with the heat gun, it felt better that way, and made it slightly easier to assess the drill spacing of the metal do-hicky. Never do that cold, learnt many times the hard way. I had always doubted planned obsolescene but occams razor says that is what these guys were up to, they make a lot of welders, and blind freddy could see a 4 mm plastic pin bending over the years, somewhere outside the warranty period, i hope it was just a grad on the drawing board and the boss was away - but smells more conspiratorial ....... Welder is great little unit now. Ps. Also noted and considered flipping the wire spool in spite of the sign, but dismissed it, the spool or post seem to be tapered, and the other way round was pretty stiff. Also had noted the short distance to the tube, but thought lengthening it was too hard. Thanks again.

Being a Land Rover nut I would have to go for a +3" lift on the wheels and a bar mounted on top of the case with spotlights on for night welding

Don't forget a section of front bumper with the obligatory LED light bar.

skotl

Forum Supporter

- Messages

- 9,967

- Location

- Edinburgh, UK

Dunno. Mine was around 30 years old and it had the plastic feed shown in the pic at the top of this pageDidn't older SIP's have metal wire feed units? from memory you could swap them for the earlier plastic types.

Sean

Another 602 fan

- Messages

- 1,460

likewise my sip 105 is probably getting on for 20 yrs old and has the plastic roller mech IMHO its no worse than the Cebora/Strap on ones all be it with a weedy motor.

the brace makes a bit of a difference, mainly stopping the wire popping out sideways. The biggest upgrade being getting a proper steel liner in the umbilical and the swan neck. Then you can add the power mods to stabilise the feed voltage.

can be made into a usefull tool but a Landrover chassis may be pushing it.

the brace makes a bit of a difference, mainly stopping the wire popping out sideways. The biggest upgrade being getting a proper steel liner in the umbilical and the swan neck. Then you can add the power mods to stabilise the feed voltage.

can be made into a usefull tool but a Landrover chassis may be pushing it.

Kelvinblacksmith

New Member

- Messages

- 12

- Location

- South West United Kingdom

Hi all,

I've been registered on this forum for a while now, but have been lurking quietly in the background most of the time! Great site by the way - amazing how much I've managed to learn from here.

Unfortunately, I discovered this forum after I'd purchased a Cosmo welder - probably would have gone for a different machine if I'd have known about the bad reputation SIP / Cosmo have

Anyway, I have run about half a dozen small reels through it over the last few months without any problems. Then within a couple of days of putting in a large reel, I started to experience problems with the wire feed.

The motor was turning, but the rollers were slipping and not feeding the wire through.

On closer inspection, I could see that the plastic pivot that carriers the idler roller was flexing. This resulted in the rollers being out of true, and losing the grip on the wire.

I came up with a simple solution that stops this from happening. So far, I've run another large reel through without any problems at all - wire feed is much more stable and no signs of slipping.

A couple of photos below to show the simple solution. Hopefully this will be of use to anyone who's suffering these sort of problems with their SIP / Cosmo machine. Probably worth trying before changing to a steel liner?

View attachment 1938

likewise my sip 105 is probably getting on for 20 yrs old and has the plastic roller mech IMHO its no worse than the Cebora/Strap on ones all be it with a weedy motor.

the brace makes a bit of a difference, mainly stopping the wire popping out sideways. The biggest upgrade being getting a proper steel liner in the umbilical and the swan neck. Then you can add the power mods to stabilise the feed voltage.

can be made into a usefull tool but a Landrover chassis may be pushing it.

I have just joined this group So Hi everyone .... all great advise on here and the mod to the cosmo works fine ... I am looking at the mod to add power to the feed and I found this Motor 500w and power solution just wondered what was your take on it ....http://www.banggood.com/ER11-Chuck-...or-p-1027937.html?rmmds=collection&utmid=1319 ...all the bits at the right price

Regards Kelvinblacksmith

rtbcomp

Moderator

- Messages

- 18,574

- Location

- Sheffield UK

With a minimum speed of 3000 rpm you're going to have to be pretty nifty with the torch.

Specification:

Dimension 140mm×110mm×48mm (L*W*H)

Input AC220V±10% 50/60Hz

Spindle Motor 500w

Spindle Speed 3000-12000r/min

Motor Diameter 52mm

Motor Length 208mm

Operating Voltage 100V DC

Current 6A

Speed Up to idle up to 15,000 rev / min

Torque 5000G/CM

Insulation Resistance > 2 megohms

Dielectric Strength 400V

High precision spindle runout 0.01-0.03

Specification:

Dimension 140mm×110mm×48mm (L*W*H)

Input AC220V±10% 50/60Hz

Spindle Motor 500w

Spindle Speed 3000-12000r/min

Motor Diameter 52mm

Motor Length 208mm

Operating Voltage 100V DC

Current 6A

Speed Up to idle up to 15,000 rev / min

Torque 5000G/CM

Insulation Resistance > 2 megohms

Dielectric Strength 400V

High precision spindle runout 0.01-0.03

Kelvinblacksmith

New Member

- Messages

- 12

- Location

- South West United Kingdom

I was working on the motor speed that is already installed has a reduction gearbox and without testing the installed motor I can't say .... Best I find out the speed of the motor and more importantly the torque .... I will keep reading all the great ideas from this group ... thank you for your insight