madkayaker

Pro sparkey Pro Welder

- Messages

- 13,678

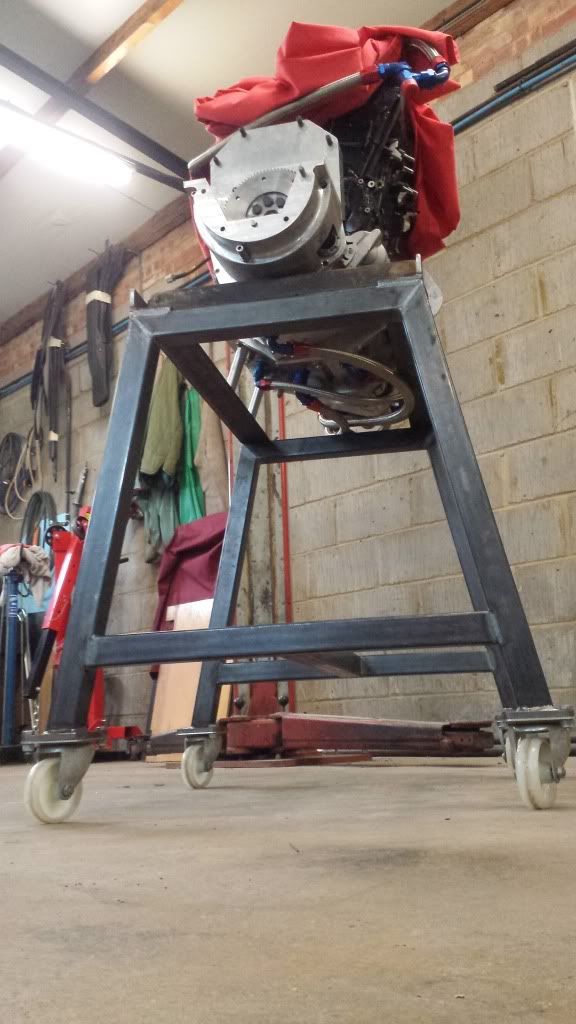

It has been a good thread though with some nice looking engineering examples

note, work have just installed a powder coater which should become very useful once the cars stripped down for final welding + paint!!

note, work have just installed a powder coater which should become very useful once the cars stripped down for final welding + paint!!