- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- CAD/CAM, 3D Printing and Laser Cutting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

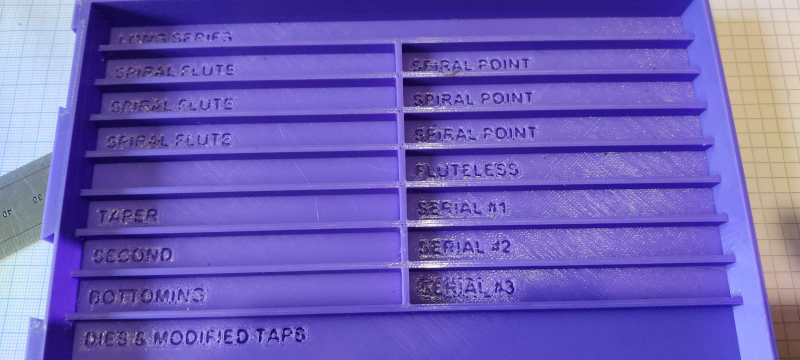

Tap & Die Storage

- Thread starter Dr.Al

- Start date

MattF

Forum Supporter

- Messages

- 18,451

- Location

- South Yorkshire

That is the thing I hear peple tweaking the printers all the time and making mods to them.

Out of the box, they work quite well enough.

It's just us lot on here, isn't it. We're peculiar sorts.

daedalusminos

Member

- Messages

- 2,401

- Location

- Norwich

Yes, I just feed the second reel in behind the first.... Bit more scary with flex filament.Has anyone on here ever printed something that took more than a reel of filament? Sounds a bit scary with the transition from one reel to the next.

personally I'd break that down into smaller parts.

daedalusminos

Member

- Messages

- 2,401

- Location

- Norwich

Text works best if it's cut in to the surface - you can get the text coloured by changing filament when it comes to do the text layers

Dr.Al

Forum Supporter

- Messages

- 2,748

- Location

- Gloucestershire, UK

Yes, I just feed the second reel in behind the first.... Bit more scary with flex filament.

personally I'd break that down into smaller parts.

Presumably that depends on your being around when the filament change is required (and it not happening at 3am for example)?

daedalusminos

Member

- Messages

- 2,401

- Location

- Norwich

Correct but if it's running low and you're not going to be about just snip it and feed the new reel in...then when that's finished back to the original.Presumably that depends on your being around when the filament change is required (and it not happening at 3am for example)?

Dr.Al

Forum Supporter

- Messages

- 2,748

- Location

- Gloucestershire, UK

I'm surprised at that to be honest. I've done text cut in on the inside of the drawers as I didn't want it sticking up, but the things I've printed (mostly stuff downloaded off the web) with text cut into the surface looked a bit pants, whereas the one I did with embossed text (this thing: https://www.prusaprinters.org/prints/110102-holder-for-t-handle-hex-allen-keys-with-tapered-he) looked really good.Text works best if it's cut in to the surface - you can get the text coloured by changing filament when it comes to do the text layers

I'll see what the slicer makes of the "GAUGES" text if I cut it into the surface.

Dr.Al

Forum Supporter

- Messages

- 2,748

- Location

- Gloucestershire, UK

Ah! Good idea.Correct but if it's running low and you're not going to be about just snip it and feed the new reel in...then when that's finished back to the original.

daedalusminos

Member

- Messages

- 2,401

- Location

- Norwich

I only cut it in 1 or 2 layers and if you've got good first layer control and a nice textured bed print it face downI'll see what the slicer makes of the "GAUGES" text if I cut it into the surface.

Dr.Al

Forum Supporter

- Messages

- 2,748

- Location

- Gloucestershire, UK

The problem is how to do it without making it weak. I'll have a ponder.personally I'd break that down into smaller parts.

Dr.Al

Forum Supporter

- Messages

- 2,748

- Location

- Gloucestershire, UK

I'll do some experimenting. One other option is to use a finer nozzle (0.25 mm instead of 0.4 mm):I only cut it in 1 or 2 layers and if you've got good first layer control and a nice textured bed print it face down

Arclikeharrypotter

Member

- Messages

- 1,243

- Location

- Northampton

Are you going to have the correct tapping drill in with each size also?

Dr.Al

Forum Supporter

- Messages

- 2,748

- Location

- Gloucestershire, UK

No. I have sets of drill bits in 0.1 mm increments and its generally easier to grab the right one from the set rather than having them stored with the taps. I'd have to keep a second set of drill bits as it would be frustrating needing a 5 mm hole and realising you have to dig in the tap drawers just because it happens to be the right size for M6.Are you going to have the correct tapping drill in with each size also?

ajlelectronics

Member

- Messages

- 11,113

- Location

- Gloucester, England

That is because we want to, rather than have too. It's part of the quest for quality / different materials and fun for some of us. If you just want to knock out some PLA items, then it is mostly plug in, level the bed and off you go.That is the thing I hear peple tweaking the printers all the time and making mods to them.

Dr.Al

Forum Supporter

- Messages

- 2,748

- Location

- Gloucestershire, UK

Also, the correct tapping size isn't always the same - it depends on whether you're doing a standard 75% engagement thread, or something a bit looser in a stubborn material (bigger drill), or using a fluteless tap etc.No. I have sets of drill bits in 0.1 mm increments and its generally easier to grab the right one from the set rather than having them stored with the taps. I'd have to keep a second set of drill bits as it would be frustrating needing a 5 mm hole and realising you have to dig in the tap drawers just because it happens to be the right size for M6.

Dr.Al

Forum Supporter

- Messages

- 2,748

- Location

- Gloucestershire, UK

The printer's had a busy night

The debossed text looks a bit shabby, but it's readable

It'll be interesting to see how it comes out on the M2/M2.5 drawer - as a result of the smaller sections, the text is smaller.

M6 one is printing now anyway.

The debossed text looks a bit shabby, but it's readable

It'll be interesting to see how it comes out on the M2/M2.5 drawer - as a result of the smaller sections, the text is smaller.

M6 one is printing now anyway.