You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tapping threads various methods .. what’s yours?

- Thread starter Noods

- Start date

premmington

Member

- Messages

- 6,562

- Location

- Norfolk

I use these and a sliding 'T' bar (plus extension if required) for hand tapping, great for restricted access which most of my jobs are.

I got a set of these - they work OK.

But last week I had to use a M18x15.mm tap on an O2 sensor thread - newish ECOboost lump of pooh - job from hell - had to take battery tray out to get poor access at back of engine for upper sensor. My left arm was cut to bits - doing it... I still bleeding now - days later if I knock the scab off the wound.

I ended up TIG brazing an old 13mm 3/8ths 12point socket on the M18 tap as my set did not go big enough (mine not a Lazer set)

Mine a Lisle set. Not sure where I got them from?

Tap+Socket+Set+-+Lisle+USA+Made+70500+Eight+Piece+1%2F4+and+3%2F8+Drive+Tap+Holders for sale online | eBay

Find many great new & used options and get the best deals for Tap+Socket+Set+-+Lisle+USA+Made+70500+Eight+Piece+1%2F4+and+3%2F8+Drive+Tap+Holders at the best online prices at eBay! Free delivery for many products!

www.ebay.co.uk

For the limited space, deep, or quick thread clearing operations, I just use the vice to push a suitable nut on to the end of the tap - then a socket, spanner, adjustable is easily used.

As for tap wrenches - using my dad's old ones - three sizes of wrench, cover pretty much all I need. The smaller one has a hole in the end of the clamp to put something handy through as a t-bar to tighten. The rest have sufficient grip.

As for tap wrenches - using my dad's old ones - three sizes of wrench, cover pretty much all I need. The smaller one has a hole in the end of the clamp to put something handy through as a t-bar to tighten. The rest have sufficient grip.

Agroshield

Member

- Messages

- 6,392

Sounds like something i need to try on some scrap…. And probably with an old tap or 2!

That is probably the worst combination to learn upon. Unknown material and worn out tooling.

When you start welding, you are never going to produce good beads on rusty bed iron using coat hangers as filler. Once you have a few years under your belt, you will then have the knowledge to make a fair go of it.

Do yourself a favour and use a piece of known mild steel, a new tapping drill of the correct size and a new, good quality tap. Once you have experience of the good stuff, you will know where, how many and the consequences of any liberties that can be taken with materials, tools and technique.

Watching people on occasion, I'm not sure they are taught why they need to reverse the tap every little while with a straight fluted hand tap - to break the chip off. I've seen people just keep winding and winding and snap!!! Not just with small taps either. Or not back-winding enough.

I remember as a young design engineer assisting in a machine build on-site. Drilling many, many holes, 4 at a time in 300 sq. 20mm plate with an enormous drill . . . it snagged once - how I didn't break my arm . . . Then tapping them all M20 by hand . . . I needed bits of pipe over the (big) tap wrench handles after a while . . . I was knackered!

I remember as a young design engineer assisting in a machine build on-site. Drilling many, many holes, 4 at a time in 300 sq. 20mm plate with an enormous drill . . . it snagged once - how I didn't break my arm . . . Then tapping them all M20 by hand . . . I needed bits of pipe over the (big) tap wrench handles after a while . . . I was knackered!

Agroshield

Member

- Messages

- 6,392

I have always liked the look of the Big Gator tapping guides:

Too mean to buy one though and not yet made one.

With the explosion of 3D printing, there are numerous options there:

www.thingiverse.com

www.thingiverse.com

www.thingiverse.com

www.thingiverse.com

www.thingiverse.com

www.thingiverse.com

The last one is a good example of what is possible - it is designed for a very specific purpose in the same way as the drilling jig that Pete. showed elsewhere.

Too mean to buy one though and not yet made one.

With the explosion of 3D printing, there are numerous options there:

Tapping Jig by Nikischniggi

Hey, everyone! I guess this thing can be had for a couple quid at your local hardware store but since I wanted to model something in Rhino, I made this thing. It is a guide or a jig to help you tap pilot holes perfectly straigt. Ranges from 10mm to 1mm. No imperial units.. crack open a pabst...

Tapping guides by CaptainObvious

Update 27/7/16: Added guide for M6 tap A set of guides for hand tapping threads, they fit M2 to M5 taps. It's much easier to do the job using one of these, not only do they make perfectly straight threads, it takes a lot less effort too.

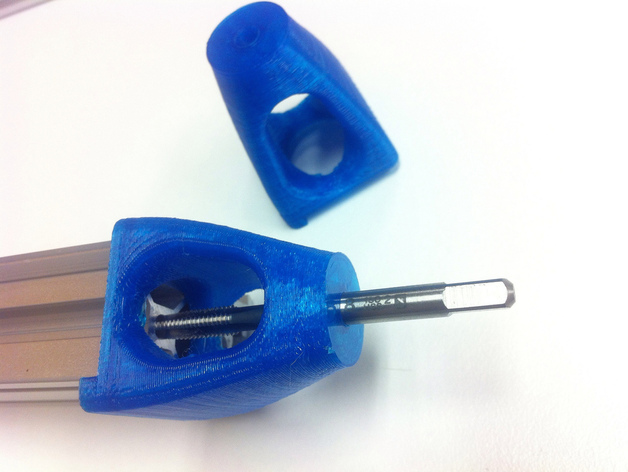

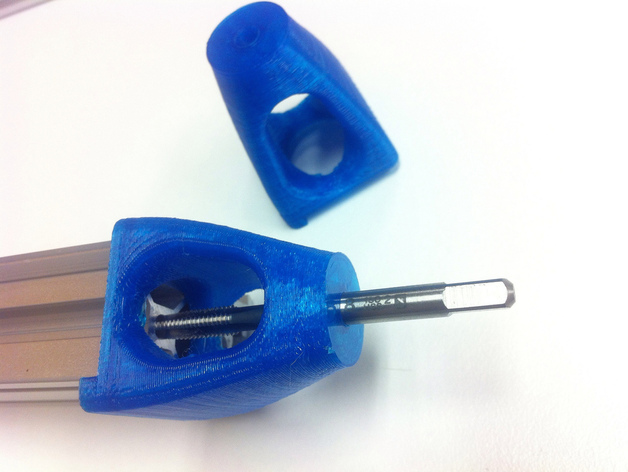

M5 Tapping Guide for MakerSlide by scottmayson

Tap straight parallel threads in MakerSlide with this tapping guide.

The last one is a good example of what is possible - it is designed for a very specific purpose in the same way as the drilling jig that Pete. showed elsewhere.

Morrisman

Forum Supporter

- Messages

- 9,074

- Location

- Staffordshire, England

I still have the tap wrench I made as an apprentice at college, in 1976. It works perfectly.A decent tap wrench of the right size.

There's not a great deal to go wrong with two bars, a notch in each, couple of tapped and a couple of clear holes, couple of screws . .I still have the tap wrench I made as an apprentice at college, in 1976. It works perfectly.

- Messages

- 23,845

- Location

- Birmingham

Still got mine somewhere, think it was made of hex bar.I still have the tap wrench I made as an apprentice at college, in 1976. It works perfectly.

Morrisman

Forum Supporter

- Messages

- 9,074

- Location

- Staffordshire, England

Mine was round bar, but then we had to hacksaw and file finish it, cut the middle out etc, all by hand. A learning experience, along hand making with a mic stand, G clamp etc.Still got mine somewhere, think it was made of hex bar.

Kram

Member

- Messages

- 8,372

- Location

- Sussex

I'd just point out that mild steel is, in my experience, the most variable of all types of metal! Responsible for most of my broken lathe inserts and taps. One area cuts fine followed by a hard spot. That seems to be only round bar, plate and sq tube have not given me any issues.That is probably the worst combination to learn upon. Unknown material and worn out tooling.

When you start welding, you are never going to produce good beads on rusty bed iron using coat hangers as filler. Once you have a few years under your belt, you will then have the knowledge to make a fair go of it.

Do yourself a favour and use a piece of known mild steel, a new tapping drill of the correct size and a new, good quality tap. Once you have experience of the good stuff, you will know where, how many and the consequences of any liberties that can be taken with materials, tools and technique.

Id suggest aluminium or an unhardened carbon steel grade, as my preferance.

A new, decent sharp machine tap will also cut 100x better than most sets of 3 hand taps, new or worn.