Brad93

Member

- Messages

- 18,338

- Location

- Essex, United Kingdom

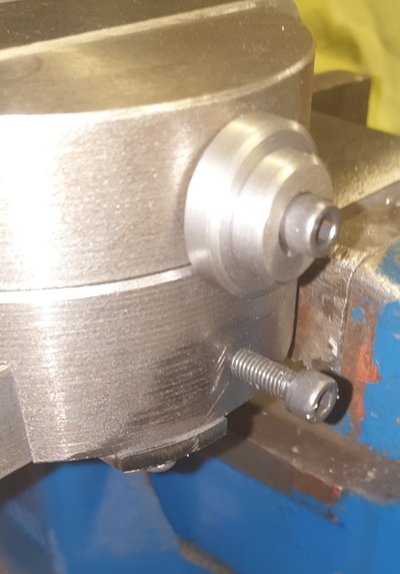

60 degree included angleBit of a learning day today doing the other part of the dovetail slide,. First thing I learnt was the 60 stamped on the side of the cutter don't mean 60 degree angle,

unless I am missing something, or they have to be read with both sides of the angled bits. The first cut, well lets just say didn't go to well,

To much angle

View attachment 268764

and the piece I had was then to narrow, after sorting another piece of steel out it got better when I halved the 60 to 30 and it went well. It took me while to figure out how to get the angle but once the penny drop, it was just a case of swivelling the vice and mill head, I did have to remove the back chip shield I made to get the table well up but he ho only 2 bolts.

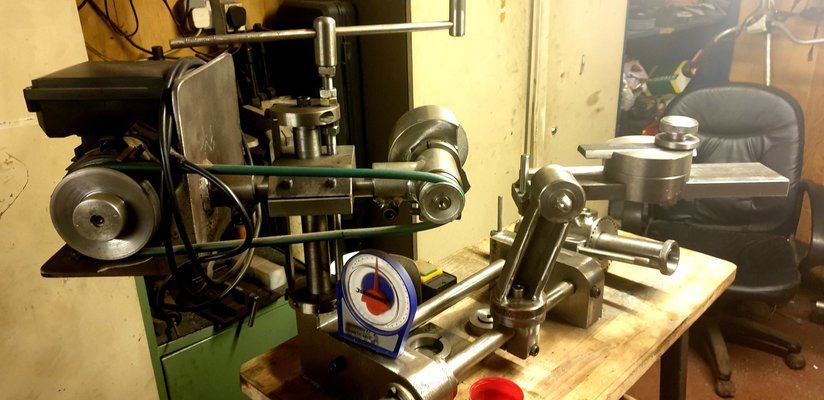

View attachment 268767

The Kearny Trecker is a brilliant milling machine, and to think I did not want it when father first brought it in,Im so lucky.

I also milled a 10mm wide slot 4mm deep to act as the slide stop and the counter sunk hole for the slide handle.

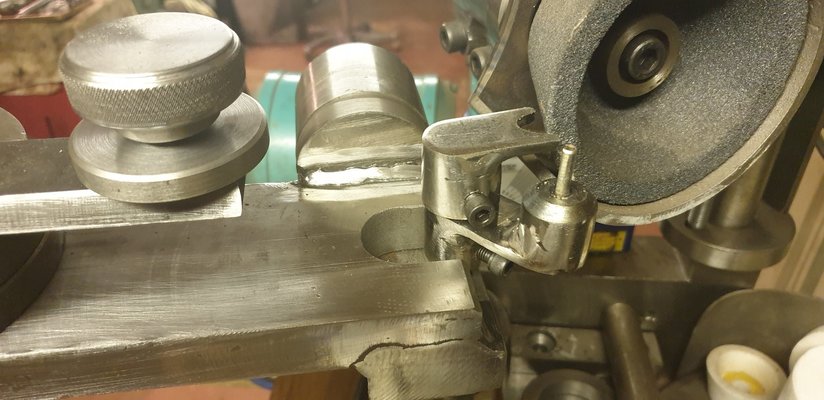

View attachment 268766

There was one other cock up today the slide handle hole was meant to do an M8 threaded hole but I drilled it 8mm, no biggy though as I have now decided to make larger threaded hole and use a M10 bolt.

View attachment 268768

Wowwowwewa I like.

View attachment 268765

That was my bit for today in the shop, I did go and buy an old Nissan pickup truck,I am hopfully going to do it up for work if I can get the parts, but that will be another story.

Cheers all

Jord

I may learn something

I may learn something