jordhandson

Member

- Messages

- 1,446

- Location

- Dorset

Mitsubishi are Japanese.

Any of their tools should be high quality.

oops

oops

Mitsubishi are Japanese.

Any of their tools should be high quality.

oops

oops

Don’t worry you’re not doing milling at 15000rpm

sorted I do feel a numpty sometimesthe holes are for cooling fluid going through them

EHI will have a look around as they may not be ant good as my Kerany trecker dont have fluid in the head, it on the outside.

OMG what a result.

I been doing some reaserch on these bits first looked for Guehring bits found them on the Guehring the tool company then found on the net the Mitsubishi SSA drill bits there all carbide drills pretty high end stuff. I will have to definitely blag them off father and only use them for special drilling and milling jobs

Ive down loaded the Mitsubishi SSA drill bit Cutting Condition and I think I have found the drill that will drill those bead roller dies I hardened.

Still looking for this one though is it for milling or drilling

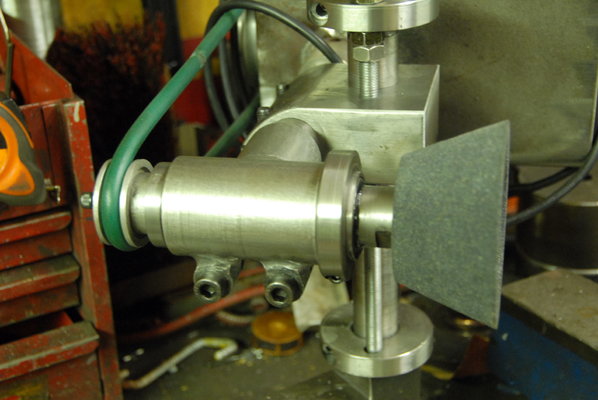

View attachment 208247

Could be a counterbore, with the cone for locating / piloting in an existing drilled hole - is the cone point sharp, with a relief so it cuts?

Carbide definitely feels and looks different, weighs about twice as much as the same size HSS cutter - almost as heavy as gold, heavier than lead! You'll need the right wheel on your TCG to sharpen it, green grit is OK for roughing but won't produce a good edge (more chipped into shape than ground)!

Dave H. (the other one)

this ones beaten me at the moment, yes the point is sharp with a relief. I dint know they could be sharpened will have to look into that. Upping the game with the tools don't half opens a can of worms. Gone are the days of doing it all with the angle grinder ha ha.

this ones beaten me at the moment, yes the point is sharp with a relief. I dint know they could be sharpened will have to look into that. Upping the game with the tools don't half opens a can of worms. Gone are the days of doing it all with the angle grinder ha ha.

you can sharpen inserts as well

just incase you dont know this

i would suggest you make that cover a little wider than what you are doing

id rather that disc give inside of it an dhave soemwhere for it to go than close proximity it has got

if you look at the design of any grinding machine it has an 1/2-1" clearance around the disk and its the same with big grinders

they kinda have a relief gap between grinding disc and the sides i presume its to allow the disc to disintergrate within the shielding

yours really has no space so if it gives its coming at you

others that use them might have other reasons for this gapping with grinding machines or @Parm might know

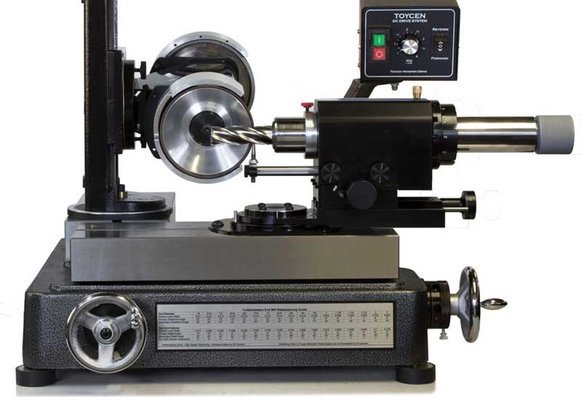

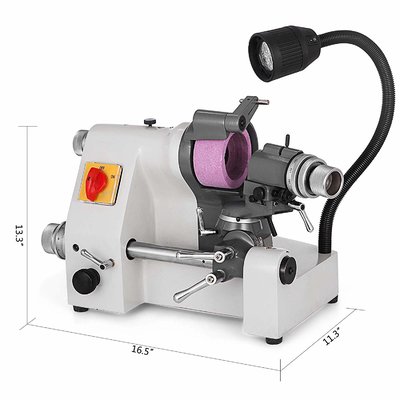

From all the research ive done on these universal tool and cutter grinders they all have seam to have approx 5mm clearance, here's a few examples.

View attachment 209846 View attachment 209847 View attachment 209848 View attachment 209849 View attachment 209850

On the 100mm wheel I have actually 6mm. Also the 6mm clearance is only the last few mm as its a cup wheel.

I do intend to mainly use diamond wheels.

Through coolant adapters I have a bucket of iso 40 ones , which are too tidley for my manly machinery@Hood's the chap to explain about 'through the head' coolant delivery.