The resident Forum experts on coil rewinding are @zeppelin builder and @Retired

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tradesmig 130 not doing anything!

- Thread starter Hairyjon

- Start date

Hi,

Thanks for the mention eddie49.

I adopted restoring vintage valve radios as a winter's hobby and spent ten years doing this until I packed it in and moved on to other hobbies. Right from the very start it became clear to me many such restorers were terrified of faulty transformers they not understanding transformers but aware of the rewinding costs involved.

Rewinding a transformer is rightfully costly because of the amount of labour involved and compared to other professions little profit is actually made by the rewinder; enameled copper wire is expensive to a home workshop but I worked for an electric motor manufacturer where full wagon loads of copper wire were common even a scrap wagon would leave with a full load.

As I became more proficient with the restorations I wondered just how difficult it would be to rewind a transformer; I had many books on radio work and had a small book entitled "Wireless Coils, Chokes and Transformers" by the author F.J.Camm. The section on transformers only runs to a few pages but just these few pages set me off rewinding and winding from scratch all kinds of transformers. These books are available second hand for anyone interested.

Regarding your contactor coil; you don't need to know what voltage it is indeed you need to know very little about it. Be very careful in removing the coil noting all connections which is important; a simple sketch with notes will do nicely. Once the coil is on the bench then remove the outer insulation to expose the first layer of winding turns; count the turns as they are unwound but an easy method is to count the layer before unwinding and make a note of the number; the coil will be neatly wound so now simply keep unwinding but note the number of layers; having unwound and noted the information the winding will then change to a different size of wire; many of the transformers I wound had a number of coils many even had "tappings" but by taking care and noting every little detail the transformer will be unwound leaving just the former (bobbin). As unwinding progresses the fault will make itself known as a break in the wire.

I could go on at length but it's possible the contactor coil is just a single coil of wire only having one winding making it very simple indeed to rewind; I've never rewound a contactor coil but feel anyone with an home workshop would find little difficulty in rewinding such a coil. The problems found to make it difficult are the embedded coils either embedded in tar or resin; tar can be melted which is an incredibly messy job but the resin types are disposable and need to be completely replaced.

I've seen many methods of wire winding and a browse of YouTube is sure to have videos on the subject; please don't feel intimidated by coil or transformer winding; having rewound the first successfully it all becomes so much easier; no one at all taught me or showed me I started from scratch and found transformers and coils etc to be very interesting. Rewinding is reasonably easy because all the information is already there; designing a bespoke transformer is much more difficult but I progressed into this and wound transformers for my own needs as in power supplies.

Once you have the coil out inspect it for identification details; many electrical stores selling motor starters etc carry stocks of assorted coils and you might get lucky.

As to rewinding such a coil once the wire is unwound then identical gauge new enameled copper wire needs to be bought; this isn't difficult because you'll need to very accurately measure the wire gauge (thickness) either with a micrometer or digital vernier caliper; weigh the original wire then buy more than this;

https://www.wires.co.uk/acatalog/cu_enam.html

Just an example above of a wire supplier.

My first transformer rewind was a radio output transformer; it was much easier than I imagined; as with your coil I already had everything worked out for me; I knew wire sizes and number of turns etc so all I needed to do was to replace the wire; I went into transformer winding with great interest but for me it was costly because I bought winding machines both manual and electric.

Years ago I sold all my winders and wire closing my radio shack and no longer touch such things having moved onto other hobbies.

Kind regards, Colin.

My radio shack with a vintage radio chassis on the bench; this work is extremely dangerous and I don't encourage any novice to follow my lead; one mistake with a chassis under mains power could prove the last mistake ever made. Sorry about picture quality many of these old pictures were taken in very poor winter conditions.

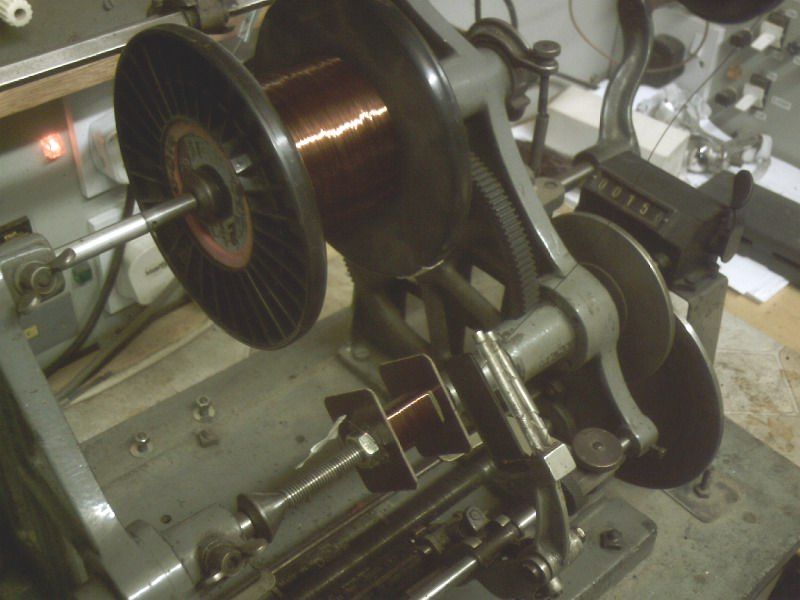

Two German Aumann electric coil winders.

AVO Douglas manual coil winder which wound many of my transformers and coils. Please note there is a huge difference between a coil and a transformer; a coil is very simple and basic and I think the contactor will just have a coil?

I fully restored this very special AVO Wave Winder; I used to submit and have articles printed in "The Bulletin" The British Vintage Wireless Society publication.

https://www.bvws.org.uk/

Here's a transformer wound from scratch with home made former.

Another transformer.

A transformer for a TV.

Home made former (bobbin) I made lots of these in many sizes the smaller ones often out of cereal cartons.

Winding underway; some on the small radio output transformers could have as many as 3,000 turns of extremely fine wire just in one coil.

Here's a 75kg transformer being wound to suit my specifications; the wire here being household heavy conduit wire; the long item is my idea; it's what I call a shuttle to aid winding and it worked so well I'm credited with the idea.

I'm completely self taught in winding so I'm no expert but having grasped the winding basics from Camm's excellent book I progressed rapidly into winding all kinds of coils and transformers; I used to wind field windings and tuning coils too; Just passing a bit of time because I'm rained off at the moment.

Thanks for the mention eddie49.

I adopted restoring vintage valve radios as a winter's hobby and spent ten years doing this until I packed it in and moved on to other hobbies. Right from the very start it became clear to me many such restorers were terrified of faulty transformers they not understanding transformers but aware of the rewinding costs involved.

Rewinding a transformer is rightfully costly because of the amount of labour involved and compared to other professions little profit is actually made by the rewinder; enameled copper wire is expensive to a home workshop but I worked for an electric motor manufacturer where full wagon loads of copper wire were common even a scrap wagon would leave with a full load.

As I became more proficient with the restorations I wondered just how difficult it would be to rewind a transformer; I had many books on radio work and had a small book entitled "Wireless Coils, Chokes and Transformers" by the author F.J.Camm. The section on transformers only runs to a few pages but just these few pages set me off rewinding and winding from scratch all kinds of transformers. These books are available second hand for anyone interested.

Regarding your contactor coil; you don't need to know what voltage it is indeed you need to know very little about it. Be very careful in removing the coil noting all connections which is important; a simple sketch with notes will do nicely. Once the coil is on the bench then remove the outer insulation to expose the first layer of winding turns; count the turns as they are unwound but an easy method is to count the layer before unwinding and make a note of the number; the coil will be neatly wound so now simply keep unwinding but note the number of layers; having unwound and noted the information the winding will then change to a different size of wire; many of the transformers I wound had a number of coils many even had "tappings" but by taking care and noting every little detail the transformer will be unwound leaving just the former (bobbin). As unwinding progresses the fault will make itself known as a break in the wire.

I could go on at length but it's possible the contactor coil is just a single coil of wire only having one winding making it very simple indeed to rewind; I've never rewound a contactor coil but feel anyone with an home workshop would find little difficulty in rewinding such a coil. The problems found to make it difficult are the embedded coils either embedded in tar or resin; tar can be melted which is an incredibly messy job but the resin types are disposable and need to be completely replaced.

I've seen many methods of wire winding and a browse of YouTube is sure to have videos on the subject; please don't feel intimidated by coil or transformer winding; having rewound the first successfully it all becomes so much easier; no one at all taught me or showed me I started from scratch and found transformers and coils etc to be very interesting. Rewinding is reasonably easy because all the information is already there; designing a bespoke transformer is much more difficult but I progressed into this and wound transformers for my own needs as in power supplies.

Once you have the coil out inspect it for identification details; many electrical stores selling motor starters etc carry stocks of assorted coils and you might get lucky.

As to rewinding such a coil once the wire is unwound then identical gauge new enameled copper wire needs to be bought; this isn't difficult because you'll need to very accurately measure the wire gauge (thickness) either with a micrometer or digital vernier caliper; weigh the original wire then buy more than this;

https://www.wires.co.uk/acatalog/cu_enam.html

Just an example above of a wire supplier.

My first transformer rewind was a radio output transformer; it was much easier than I imagined; as with your coil I already had everything worked out for me; I knew wire sizes and number of turns etc so all I needed to do was to replace the wire; I went into transformer winding with great interest but for me it was costly because I bought winding machines both manual and electric.

Years ago I sold all my winders and wire closing my radio shack and no longer touch such things having moved onto other hobbies.

Kind regards, Colin.

My radio shack with a vintage radio chassis on the bench; this work is extremely dangerous and I don't encourage any novice to follow my lead; one mistake with a chassis under mains power could prove the last mistake ever made. Sorry about picture quality many of these old pictures were taken in very poor winter conditions.

Two German Aumann electric coil winders.

AVO Douglas manual coil winder which wound many of my transformers and coils. Please note there is a huge difference between a coil and a transformer; a coil is very simple and basic and I think the contactor will just have a coil?

I fully restored this very special AVO Wave Winder; I used to submit and have articles printed in "The Bulletin" The British Vintage Wireless Society publication.

https://www.bvws.org.uk/

Here's a transformer wound from scratch with home made former.

Another transformer.

A transformer for a TV.

Home made former (bobbin) I made lots of these in many sizes the smaller ones often out of cereal cartons.

Winding underway; some on the small radio output transformers could have as many as 3,000 turns of extremely fine wire just in one coil.

Here's a 75kg transformer being wound to suit my specifications; the wire here being household heavy conduit wire; the long item is my idea; it's what I call a shuttle to aid winding and it worked so well I'm credited with the idea.

I'm completely self taught in winding so I'm no expert but having grasped the winding basics from Camm's excellent book I progressed rapidly into winding all kinds of coils and transformers; I used to wind field windings and tuning coils too; Just passing a bit of time because I'm rained off at the moment.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 13,078

- Location

- NE London - UK

you'll need to very accurately measure the wire gauge (thickness) either with a micrometer or digital vernier caliper

Bear in mind that there is lacquer on the wire if you can't find a wire that exactly matches your measured size. It won't differ by much but will, of course, measure slightly over size.

Hi,

Thanks and good point Seadog. When I've bought enameled copper wire I've found the wire to be the same gauge as I measure the original wire. I'd be cautious regarding buying even slightly thicker gauge wire especially for transformers because the transformer lamination window possible won't accept the correct number of turns; if in doubt though simply burn the wire to be measured this will remove the enamel?

I made one very simple mistake during all my time doing winding; it was a mains transformer for a vintage radio and the very first one I attempted; the secondary winding was center tapped for the full wave rectifier and I think 350V were needed so I wound on the primary for our 240V supply then wound on the secondary winding center tapping it. Upon reassembling and running the radio I found volume to be very low? After lots of checking I found 175V each side of the tap; a very simple mistake for a novice and one never forgotten; I removed the transformer and snipped the center tap connection then I wound on double the turns giving 700V now each side of the tap gave the correct 350V. For general needs a few turns less or more will make little difference. These transformers had multiple windings and taps and were interesting to rewind but it took a lot of time. I eventually found the way to determine the turns ratio; I could find either the panel lamp or heater winding these being thicker wire and with few turns but I also knew the voltage so if the winding was for 6V and there were 24 turns it was very easy to find it had a ratio of 4 to 1 and I could work out all the voltages with a few simple sums.

Kind regards, Colin.

Thanks and good point Seadog. When I've bought enameled copper wire I've found the wire to be the same gauge as I measure the original wire. I'd be cautious regarding buying even slightly thicker gauge wire especially for transformers because the transformer lamination window possible won't accept the correct number of turns; if in doubt though simply burn the wire to be measured this will remove the enamel?

I made one very simple mistake during all my time doing winding; it was a mains transformer for a vintage radio and the very first one I attempted; the secondary winding was center tapped for the full wave rectifier and I think 350V were needed so I wound on the primary for our 240V supply then wound on the secondary winding center tapping it. Upon reassembling and running the radio I found volume to be very low? After lots of checking I found 175V each side of the tap; a very simple mistake for a novice and one never forgotten; I removed the transformer and snipped the center tap connection then I wound on double the turns giving 700V now each side of the tap gave the correct 350V. For general needs a few turns less or more will make little difference. These transformers had multiple windings and taps and were interesting to rewind but it took a lot of time. I eventually found the way to determine the turns ratio; I could find either the panel lamp or heater winding these being thicker wire and with few turns but I also knew the voltage so if the winding was for 6V and there were 24 turns it was very easy to find it had a ratio of 4 to 1 and I could work out all the voltages with a few simple sums.

Kind regards, Colin.

Monkey Harris

Member

- Messages

- 958

- Location

- northampton nn5

Hi,

Thanks for the mention eddie49.

I adopted restoring vintage valve radios as a winter's hobby and spent ten years doing this until I packed it in and moved on to other hobbies. Right from the very start it became clear to me many such restorers were terrified of faulty transformers they not understanding transformers but aware of the rewinding costs involved.

Rewinding a transformer is rightfully costly because of the amount of labour involved and compared to other professions little profit is actually made by the rewinder; enameled copper wire is expensive to a home workshop but I worked for an electric motor manufacturer where full wagon loads of copper wire were common even a scrap wagon would leave with a full load.

As I became more proficient with the restorations I wondered just how difficult it would be to rewind a transformer; I had many books on radio work and had a small book entitled "Wireless Coils, Chokes and Transformers" by the author F.J.Camm. The section on transformers only runs to a few pages but just these few pages set me off rewinding and winding from scratch all kinds of transformers. These books are available second hand for anyone interested.

Regarding your contactor coil; you don't need to know what voltage it is indeed you need to know very little about it. Be very careful in removing the coil noting all connections which is important; a simple sketch with notes will do nicely. Once the coil is on the bench then remove the outer insulation to expose the first layer of winding turns; count the turns as they are unwound but an easy method is to count the layer before unwinding and make a note of the number; the coil will be neatly wound so now simply keep unwinding but note the number of layers; having unwound and noted the information the winding will then change to a different size of wire; many of the transformers I wound had a number of coils many even had "tappings" but by taking care and noting every little detail the transformer will be unwound leaving just the former (bobbin). As unwinding progresses the fault will make itself known as a break in the wire.

I could go on at length but it's possible the contactor coil is just a single coil of wire only having one winding making it very simple indeed to rewind; I've never rewound a contactor coil but feel anyone with an home workshop would find little difficulty in rewinding such a coil. The problems found to make it difficult are the embedded coils either embedded in tar or resin; tar can be melted which is an incredibly messy job but the resin types are disposable and need to be completely replaced.

I've seen many methods of wire winding and a browse of YouTube is sure to have videos on the subject; please don't feel intimidated by coil or transformer winding; having rewound the first successfully it all becomes so much easier; no one at all taught me or showed me I started from scratch and found transformers and coils etc to be very interesting. Rewinding is reasonably easy because all the information is already there; designing a bespoke transformer is much more difficult but I progressed into this and wound transformers for my own needs as in power supplies.

Once you have the coil out inspect it for identification details; many electrical stores selling motor starters etc carry stocks of assorted coils and you might get lucky.

As to rewinding such a coil once the wire is unwound then identical gauge new enameled copper wire needs to be bought; this isn't difficult because you'll need to very accurately measure the wire gauge (thickness) either with a micrometer or digital vernier caliper; weigh the original wire then buy more than this;

https://www.wires.co.uk/acatalog/cu_enam.html

Just an example above of a wire supplier.

My first transformer rewind was a radio output transformer; it was much easier than I imagined; as with your coil I already had everything worked out for me; I knew wire sizes and number of turns etc so all I needed to do was to replace the wire; I went into transformer winding with great interest but for me it was costly because I bought winding machines both manual and electric.

Years ago I sold all my winders and wire closing my radio shack and no longer touch such things having moved onto other hobbies.

Kind regards, Colin.

View attachment 235553

My radio shack with a vintage radio chassis on the bench; this work is extremely dangerous and I don't encourage any novice to follow my lead; one mistake with a chassis under mains power could prove the last mistake ever made. Sorry about picture quality many of these old pictures were taken in very poor winter conditions.

View attachment 235554

Two German Aumann electric coil winders.

View attachment 235555

AVO Douglas manual coil winder which wound many of my transformers and coils. Please note there is a huge difference between a coil and a transformer; a coil is very simple and basic and I think the contactor will just have a coil?

View attachment 235556

I fully restored this very special AVO Wave Winder; I used to submit and have articles printed in "The Bulletin" The British Vintage Wireless Society publication.

https://www.bvws.org.uk/

View attachment 235557

Here's a transformer wound from scratch with home made former.

View attachment 235558

Another transformer.

View attachment 235559

A transformer for a TV.

View attachment 235560

Home made former (bobbin) I made lots of these in many sizes the smaller ones often out of cereal cartons.

View attachment 235561

Winding underway; some on the small radio output transformers could have as many as 3,000 turns of extremely fine wire just in one coil.

View attachment 235562

Here's a 75kg transformer being wound to suit my specifications; the wire here being household heavy conduit wire; the long item is my idea; it's what I call a shuttle to aid winding and it worked so well I'm credited with the idea.

I'm completely self taught in winding so I'm no expert but having grasped the winding basics from Camm's excellent book I progressed rapidly into winding all kinds of coils and transformers; I used to wind field windings and tuning coils too; Just passing a bit of time because I'm rained off at the moment.

fascinating work

you have inspired me to have a look at rewinding the coil..

its quite small 1'' x 1.5''...

I have a few oven fan motors that have similar wire on them ...