You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Two post lift - wheel adaptors

- Thread starter Shroppy

- Start date

A little more than an inch but it's set up for road, the main benefit is that lifting from the wheels I'll gain the distance from the chassis to the ground plus bit for wheel drop in head room.Unrelated but how much drop do you actually get on the suspension when lifted?

Mine is a track based but has 4" total and only 1" of that is droop

A little more than an inch but it's set up for road, the main benefit is that lifting from the wheels I'll gain the distance from the chassis to the ground plus bit for wheel drop in head room.

Use longer up stands

I can see the point for storage so the the arms are lowest point but you could achieve the same by driving on to some blocks of wood and extending the pads fully then lifting the car. I sometimes have to do that on really low cars.

I can see the adapters being a load of hassle. I have a 2 post and 4 post at home and have worked on may car using a trolley jack because I couldn't be bothered to move the vehicles in the way and on the ramps. Once there is inconvenience you stop using things.

I think another solution would be two cross beams that had uplifts on the ends that just cleared the jacking pads when sat on the floor. If they had cups in the ends they couldn't move but would dead easy to take off and store. You could then have some marks on the floor for alignment and just drive on to them. For a 600kg car 25x25 frame with braces would be enough. Making them wider would limit the inward leverage on the arms.

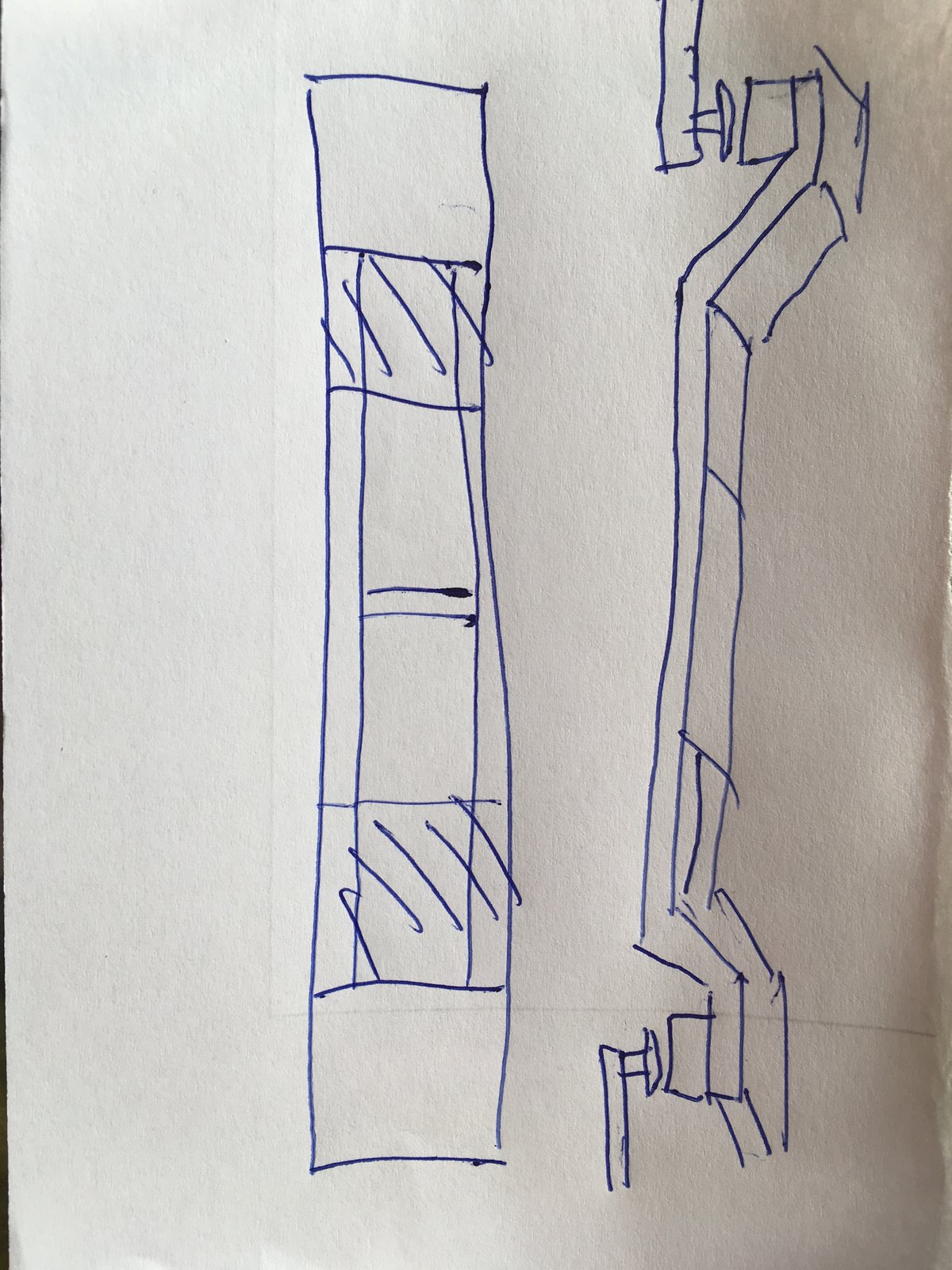

Not the best picture but the plates on the beam could be moveable. The whole frame would be light enough to just lift away and hang on the wall.

I can see the adapters being a load of hassle. I have a 2 post and 4 post at home and have worked on may car using a trolley jack because I couldn't be bothered to move the vehicles in the way and on the ramps. Once there is inconvenience you stop using things.

I think another solution would be two cross beams that had uplifts on the ends that just cleared the jacking pads when sat on the floor. If they had cups in the ends they couldn't move but would dead easy to take off and store. You could then have some marks on the floor for alignment and just drive on to them. For a 600kg car 25x25 frame with braces would be enough. Making them wider would limit the inward leverage on the arms.

Not the best picture but the plates on the beam could be moveable. The whole frame would be light enough to just lift away and hang on the wall.

I can see the point for storage so the the arms are lowest point but you could achieve the same by driving on to some blocks of wood and extending the pads fully then lifting the car. I sometimes have to do that on really low cars.

I can see the adapters being a load of hassle. I have a 2 post and 4 post at home and have worked on may car using a trolley jack because I couldn't be bothered to move the vehicles in the way and on the ramps. Once there is inconvenience you stop using things.

I think another solution would be two cross beams that had uplifts on the ends that just cleared the jacking pads when sat on the floor. If they had cups in the ends they couldn't move but would dead easy to take off and store. You could then have some marks on the floor for alignment and just drive on to them. For a 600kg car 25x25 frame with braces would be enough. Making them wider would limit the inward leverage on the arms.

Not the best picture but the plates on the beam could be moveable. The whole frame would be light enough to just lift away and hang on the wall.

View attachment 191773

I like this idea a lot, I wonder how best to make them such that the overall width can be adjusted to accommodate different wheel bases....

I'd like to end up with something that I can park the Series 1 land rover (1200kg) on too ultimately.

RaceDiagnostics

Member

- Messages

- 3,534

- Location

- Broughty Ferry

I found some pics of my mates solution.

Full story and build in this thread.

https://forums.mbclub.co.uk/threads/a-new-toy.172682/#post-1915007

Full story and build in this thread.

https://forums.mbclub.co.uk/threads/a-new-toy.172682/#post-1915007

I like this idea a lot, I wonder how best to make them such that the overall width can be adjusted to accommodate different wheel bases....

I'd like to end up with something that I can park the Series 1 land rover (1200kg) on too ultimately.

If you make the platforms wide enough that the arms sit parallel with vehicle ie at their normal rest point then you will have the length adjustment of the arms available to do wheel base adjustment

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

@RaceDiagnostics Thanks for sharing that, your mate has excellent taste in cars

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,211

- Location

- Sevenoaks, UK

I really shouldn't be encouraged but I've rewired two 3-phase 2 posts to run on 230V for the BiL...

The first a Bradbury, I got to this after the BiL had gutted all the safetys!

https://flic.kr/p/2f3hhmD

Single phase 1.5kW motor now. Geared down with a Landrover sprocket and some 1/2" pitch chain. No up or chain break limits. Coming down, take your finger off when it reaches the first white paint mark, DON'T go past the 3rd white paint mark!

https://flic.kr/p/2f3hgqR

The latest, a Grazia. Got to this before he hacked it. Simply changed the control trannie from a 400/24 to a 230/24 (from an old paper shredder). All works a treat and all safetys intact and functioning. Same single phase motor and gearing setup as on the Bradbury

https://flic.kr/p/2eXFwzJ

The first a Bradbury, I got to this after the BiL had gutted all the safetys!

https://flic.kr/p/2f3hhmD

Single phase 1.5kW motor now. Geared down with a Landrover sprocket and some 1/2" pitch chain. No up or chain break limits. Coming down, take your finger off when it reaches the first white paint mark, DON'T go past the 3rd white paint mark!

https://flic.kr/p/2f3hgqR

The latest, a Grazia. Got to this before he hacked it. Simply changed the control trannie from a 400/24 to a 230/24 (from an old paper shredder). All works a treat and all safetys intact and functioning. Same single phase motor and gearing setup as on the Bradbury

https://flic.kr/p/2eXFwzJ