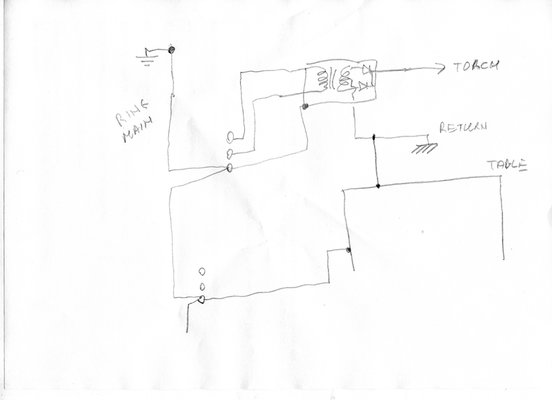

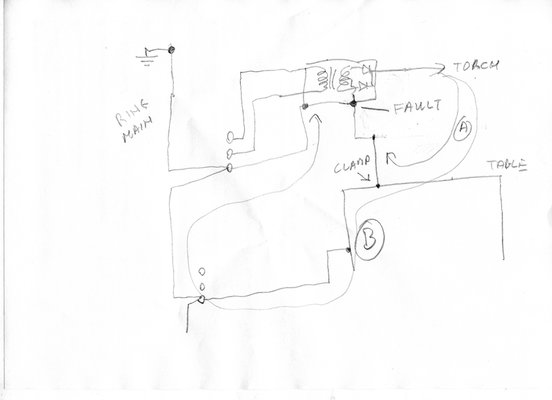

Bear in mind this problem may not be with the welder, but the way the welding return, mains earth and the workpiece are all connected together.

In any event a dedicated circuit will fry under the same circumstances, so if you're installing one, mount the wiring on the surface where it can easily be changed - but that's fixing the symptoms not the fault.

You could try wiring a current sensing relay in the mains earth and wire its (normally open) contacts across the test button of an *RCD. That way you'd be covered for earth leakage and current imbalance.

* Is there such a thing as an RCD as an RCD with a remote test button? If so that would be ideal.

Another (better) option would be to use a No Volts release (NVR) switch, and connect the normally closed contacts of the sensing relay in series with its coil, an earth current would open the contacts and drop the NVR.

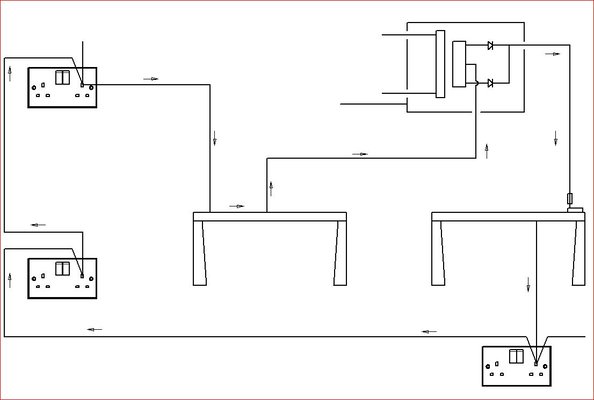

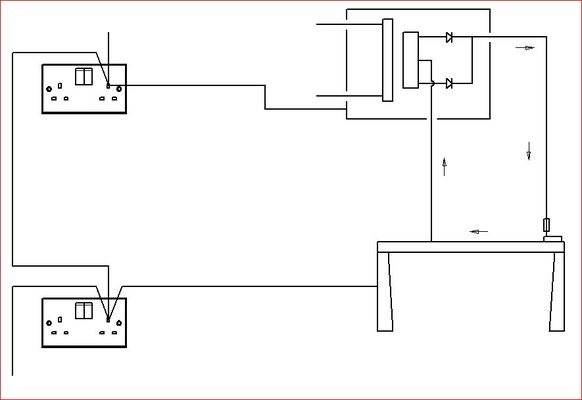

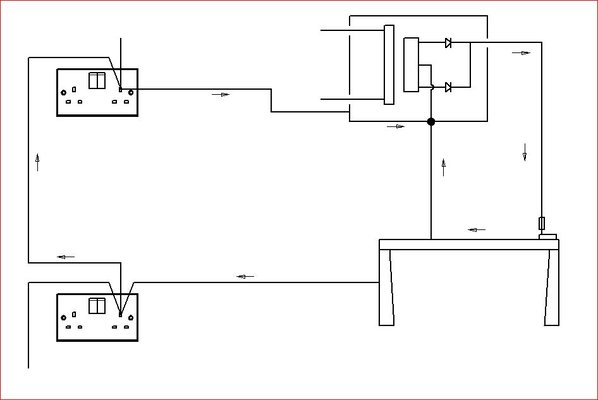

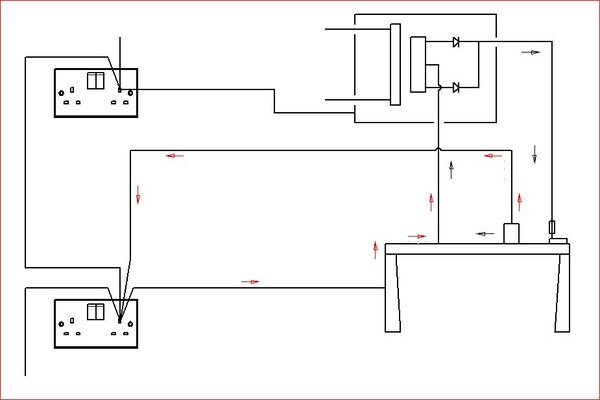

The problem was definitely with the welder because I found that the insulation was damaged by a mounting screw on the lug connecting the rectifier to the upper of the main connection lugs so that welding current was going directly to the case of the machine. I have proposed the attached scheme using two circuit breakers (Earth MCB.pdf) to the French electrician, but he's not yet replied and I'm off on holiday. I think that it does what you're proposing. MCB 1 is the normal one that you would have on the incoming power supply and protects the primary circuit. In MCB 2, the power line from MCB 1 passes through the neutral side and the earth is routed through the phase. Any major short to earth will trip MCB 2, protecting the earth wire and the secondary circuit whilst also cutting the power to the primary side.

Last edited by a moderator:

it would be negligible.

it would be negligible.