You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vacuum chamber and plastic for lid?

- Thread starter Kram

- Start date

I will be trying to build one this week.

For the lid, Chinese vac chambers seem to be 12mm acrylic, like this but much smaller.

VEVOR 1.5 Gallon Vacuum Chamber, Vacuum Degassing Chamber Glass Lid Stainless Steel Degassing Chamber Silicones for Gas Extraction and Protect Food : Amazon.co.uk: Business, Industry & Science

Buy VEVOR 1.5 Gallon Vacuum Chamber, Vacuum Degassing Chamber Glass Lid Stainless Steel Degassing Chamber Silicones for Gas Extraction and Protect Food at Amazon UK. Free delivery on eligible orders.www.amazon.co.uk

Theres a plastic shop near me that has small offcuts of 12-20mm thick acrylic and polycarbonate sheet. I'll try to get some tomorrow, but which would be better?

Acrylic can be brittle?

Polycarbonate is greatly weakened by any solvents, unsure if acrylic is degraded as much?

I may use it for epoxy/silicone resins, plaster etc.. if that makes a difference.

For the chamber, my plan is to over build it with 5mm wall/base so that its not springy. I have not tried to weld anything like this. Its a relatively low volume at a maximum of -1bar, it should be safe enough?

The vacuum chamber in your Amazon link is only £44 if bought directly from Vevor and you can buy a complete setup with a pump for £85

Kram

Member

- Messages

- 8,345

- Location

- Sussex

Would have been quicker, yes

Chamber from photo it looks like a thin spun stainless pot, so I think mine will be better

Almost done, been too busy recently.. out to lathe in a moment to finish it!

The pump, in my later link, is tempting but for the number of times it will get used/storage space taken, doesnt make sense at the moment - I'll see what the manual one is like first.

Chamber from photo it looks like a thin spun stainless pot, so I think mine will be better

Almost done, been too busy recently.. out to lathe in a moment to finish it!

The pump, in my later link, is tempting but for the number of times it will get used/storage space taken, doesnt make sense at the moment - I'll see what the manual one is like first.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Pete if you have two 1" thick rounds of Delrin perhaps sink a recessed hole in the top one and insert the thick Perspex disc on an "O" ring in a shallow groove in the Delrin the top , mastic seal the top ring via a small groove to the top of the cylinder. Putting cling film over the mastic bead to stop it gluing it to the cylinder . That way it's easily taken apart & is reuseable .Mine will have a delrin base secured with mastic, perpsex top with probably an o-ring seal.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

A decent vacuum ( Henry ? ) cleaner might also be OK to de-gas the investment slurry in the vacuum chamber quite quickly , especially if the table it sits on has a vibrator device attached to it . Once the enlarged bubbles are in motion they will rise to the top , you don't need to boil the water off under vacuum . You just need to get the gas bubbles moving away from the object being cast over .Slow(ish) but reliable is one of the Edward's Vacuum pumps. I have used mine for degassing wine, mostly. They will create a high vacuum.

To some, 14psi seems not a lot - but remember, that is the pressure and it’s the force that is important if it implodes.

Laboratory desiccators were always covered with a cloth, when evacuated.

Never seen the evacuated-can experiment on a pressure can? Or inverting a beer can, filled with steam at close to boiling point, into a sink/basin of water? If you haven’t, you clearly missed out on your science lessons.

The earliest steam engines operated at 14psi maximum. They were powerful enough to drive some large pumps.

I'm struggling with " Roundtuits " at the minute but aren't far behind you guys .. When I get setting up I'll take photos & keep notes. then post the findings & results .

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Having measured the cylinder and found the Delrin too small , one of the solutions that came to mind whilst I've been playing with you spalted beech ( Arragh shi**y stuff  ).

).

Do it so the plug has a suction hole & is easy in and too big to be pulled through by making it thick top hat with a decent thick brim that is silicone'd , slip cling film between the cylinder and the top hat so it is easy release . , stick the other end directly to the bench ?

).

).Do it so the plug has a suction hole & is easy in and too big to be pulled through by making it thick top hat with a decent thick brim that is silicone'd , slip cling film between the cylinder and the top hat so it is easy release . , stick the other end directly to the bench ?

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,188

- Location

- Sevenoaks, UK

Just putting it out there...3D printed vacuum chamber base:

https://www.thingiverse.com/thing:3443413

Wot I said!

https://www.thingiverse.com/thing:3443413

Wot I said!

Kram

Member

- Messages

- 8,345

- Location

- Sussex

It would be interesting if it can hold 3.3kN. I'll stand over there, behind a safe wall

The 5" vac chamber is pretty much done, going to test soon. I may need to cut some rubber sheet for seals but I have plenty, hidden at back of garage. Not looking forward to fishing that out!

The 5" vac chamber is pretty much done, going to test soon. I may need to cut some rubber sheet for seals but I have plenty, hidden at back of garage. Not looking forward to fishing that out!

Kram

Member

- Messages

- 8,345

- Location

- Sussex

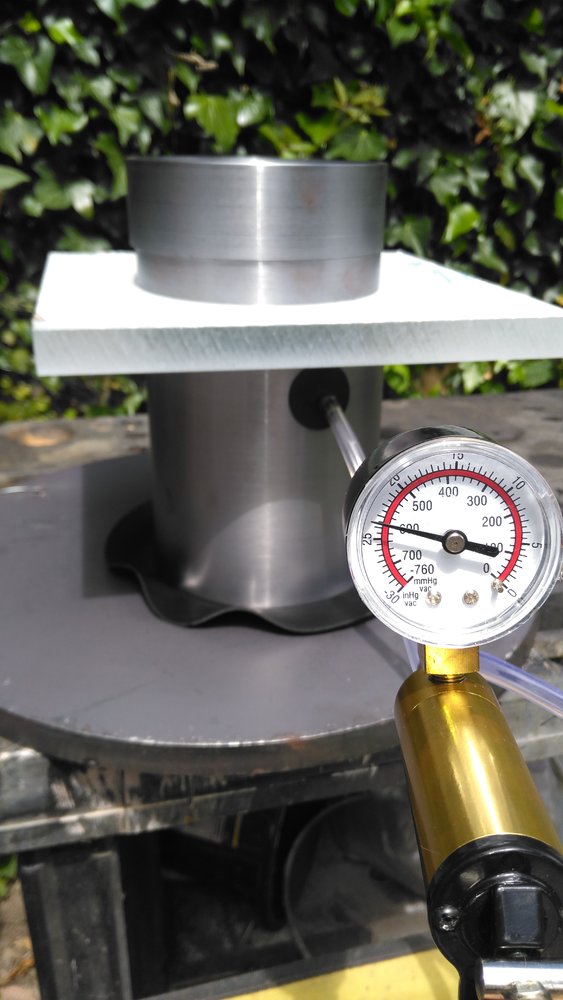

Took a while to locate rubber but easier than imagined to retrieve from the garage.

First attempt had a leak underneath on the plug,sucking the bottom seal up, ut was going to 200mmHG

Adjusted seals and added some to bolt threads

Still has a very small leak, I'll play with it and the smaller tube again later.

I added 100mm bar to reduce the volume, much quicker and over 500mmHG.

Havent removed the anti scratch off the acrylic.

First attempt had a leak underneath on the plug,sucking the bottom seal up, ut was going to 200mmHG

Adjusted seals and added some to bolt threads

Still has a very small leak, I'll play with it and the smaller tube again later.

I added 100mm bar to reduce the volume, much quicker and over 500mmHG.

Havent removed the anti scratch off the acrylic.

daedalusminos

Member

- Messages

- 2,388

- Location

- Norwich

Why has the rubber gasket puckered?

The gaskets should be donuts not discs - and I'd remove the anti-scratch, could cause a leak, joints should self seal with the rubber gaskets and flat surfaces.

The gaskets should be donuts not discs - and I'd remove the anti-scratch, could cause a leak, joints should self seal with the rubber gaskets and flat surfaces.

Kram

Member

- Messages

- 8,345

- Location

- Sussex

The bottom plate has a central bore and 3 bolt holes, which are plugged but had a small leak. Its not ideal just something I had ready to try. Finish is rough and needs a finishing pass in lathe.

Tomorrows idea, instead I will just use a flat-ish 390mm dia steel disc for the bottom

The plan is to turn the lump of delrin but I need a round tuit..

I'd be a shame to scratch it up the acrylic, I'll remove it once I find a safe place to store away from scratchy things

Tomorrows idea, instead I will just use a flat-ish 390mm dia steel disc for the bottom

The plan is to turn the lump of delrin but I need a round tuit..

I'd be a shame to scratch it up the acrylic, I'll remove it once I find a safe place to store away from scratchy things

Kram

Member

- Messages

- 8,345

- Location

- Sussex

Probably if you were going for tube on plate without any seal.

With the flat, rough plate, theres still a leak pulling air between plate and seal.

Next upgrade... I have a slab of 3/4" gauge plate, not perfect it has surface rust etc..

I think thats about the limit of the hand pump. Its not quick either. I will try with the shorter, smaller tube next. Weight compressing the seal seems to help.

Almost ready to order the Vevor pump.

Anyone know if an electric pump can be used for vacuum distillation of flammables? That may be useful. Would need to plumb the outlet into a container and not have the distilate condense, then run back into the pump

With the flat, rough plate, theres still a leak pulling air between plate and seal.

Next upgrade... I have a slab of 3/4" gauge plate, not perfect it has surface rust etc..

I think thats about the limit of the hand pump. Its not quick either. I will try with the shorter, smaller tube next. Weight compressing the seal seems to help.

Almost ready to order the Vevor pump.

Anyone know if an electric pump can be used for vacuum distillation of flammables? That may be useful. Would need to plumb the outlet into a container and not have the distilate condense, then run back into the pump

refrigeration vacuum pumps are fine with that, they can be used to vacuum out systems with lpg in them

I'm surprised your hose hasn't sucked flat

you could make a small tray for the bottom, with the rubber glued down to it and a small puddle of thick oil in it.... oil would be a lot harder to suck past the seal than air?

I'm surprised your hose hasn't sucked flat

you could make a small tray for the bottom, with the rubber glued down to it and a small puddle of thick oil in it.... oil would be a lot harder to suck past the seal than air?

Kram

Member

- Messages

- 8,345

- Location

- Sussex

Lpg is gas at STP where as Im thinking of say, alcohols/solvents which would liquify as soon as they hit the low pressure side.refrigeration vacuum pumps are fine with that, they can be used to vacuum out systems with lpg in them

hmm... you could pump water through a venture and use the suction from that?

I've never used one but the guys on the bio diesel foum use them to suck methanol into their reactors... can't remember the numbers but they can get a hell of a vacuum going

I've never used one but the guys on the bio diesel foum use them to suck methanol into their reactors... can't remember the numbers but they can get a hell of a vacuum going