Andrew Booth

New Member

- Messages

- 13

- Location

- Rotherham

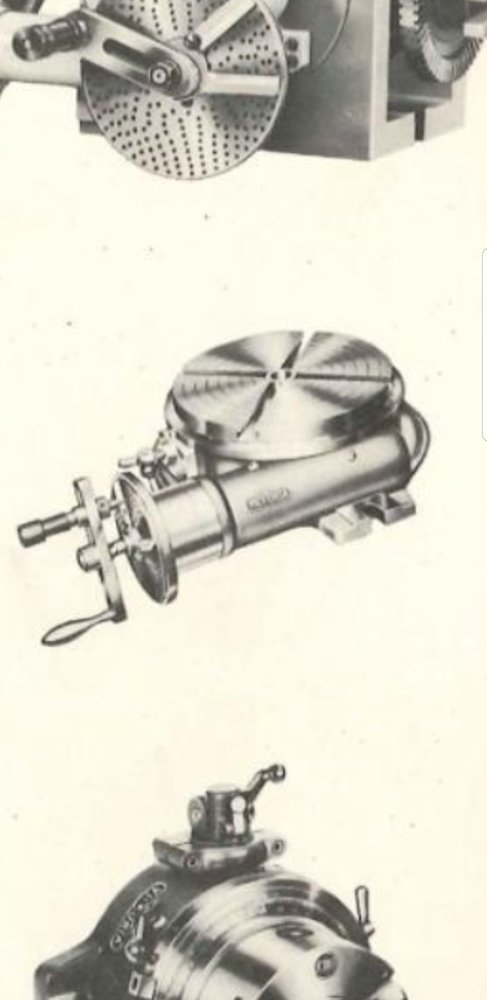

Help needed dose any body have any info on these rotary table.. I have have one but only got the 9ne indexing plate... should there be more then thr one plate...

DefinitelyCould be a good use case for laser cutter too.

Could be a good use case for laser cutter too.

Can you share a pic of the plate you have? I have an Elliot dividing head I can see if the plates are the same.

I was thinking of Co2 Laser in plastic / mdf rather than metal.The difficulty with a laser cutter is the holes: they are relatively small, compared with the plate thickness, which lasers do not like and the finish on them needs to be reasonable for the indexing pin to drop into.

There will be some similarity as the hole numbers all contain prime factors, but most dividing heads have a coarser worm ratio than rotary tables, so it is not an exact correspondence.

As an example, look at the Taiwanese Vertex rotary tables and dividing heads and compare hole numbers in their plates.

----

To the OP: the important thing to determine is the worm ratio of the table. That is, how many full turns of the handle give one full turn of the table. For that table, my guess is 90:1 but it could be 60:1 or 120:1 or 180:1. Once we know what the ratio is, there are a standard set of plates that go with each ratio.

I would also think that any 3D print version you find on thingiverse would be parameterised, so you can easily specify plate diameter, thickness, hole diameter, hole circle spacing and number of holes. See, for example, this one: https://www.thingiverse.com/thing:1908993

You could use a laser to spot mark the holes then drill them out.The difficulty with a laser cutter is the holes: they are relatively small, compared with the plate thickness, which lasers do not like and the finish on them needs to be reasonable for the indexing pin to drop into.

There will be some similarity as the hole numbers all contain prime factors, but most dividing heads have a coarser worm ratio than rotary tables, so it is not an exact correspondence.

As an example, look at the Taiwanese Vertex rotary tables and dividing heads and compare hole numbers in their plates.

----

To the OP: the important thing to determine is the worm ratio of the table. That is, how many full turns of the handle give one full turn of the table. For that table, my guess is 90:1 but it could be 60:1 or 120:1 or 180:1. Once we know what the ratio is, there are a standard set of plates that go with each ratio.

I would also think that any 3D print version you find on thingiverse would be parameterised, so you can easily specify plate diameter, thickness, hole diameter, hole circle spacing and number of holes. See, for example, this one: https://www.thingiverse.com/thing:1908993

Will take a pic when I can get to the work shop... I have part numberCan you share a pic of the plate you have? I have an Elliot dividing head I can see if the plates are the same.

Can you share a pic of the plate you have? I have an Elliot dividing head I can see if the plates are the same.

This is the plate I have on the table..sorry for taking so long to get back but not been wellCan you share a pic of the plate you have? I have an Elliot dividing head I can see if the plates are the same.

That looks very similar to the plates I have, I'll check and provide photos of the arms on mine and the plates.This is the plate I have on the table..sorry for taking so long to get back but not been well

View attachment 310803 View attachment 310804 View attachment 310805 View attachment 310806

Nowadays there are video tutorials on youtube.