You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Welder settings r tech mig 180

- Thread starter Edwardbear

- Start date

Edwardbear

Member

- Messages

- 62

- Location

- Peterborough

Its got less distance to fall over then. Perfect sense

Swift&Bold

Member

- Messages

- 986

- Location

- Dan Saff!

You need to contact R-Tech.

I weld 1mm on those settings with full penetration, sometimes even blow through (operator error), you should see at least some, if not full penetration on 1.5mm using the same settings.

I weld 1mm on those settings with full penetration, sometimes even blow through (operator error), you should see at least some, if not full penetration on 1.5mm using the same settings.

Edwardbear

Member

- Messages

- 62

- Location

- Peterborough

How much gap behold there be between the old metal and the patch? I could be making the fit too tight then not getting and penetration

Edwardbear

Member

- Messages

- 62

- Location

- Peterborough

Looking at some scrap I did a test on the weld is almost spherical on the outside of the sheer with zero penetration

Swift&Bold

Member

- Messages

- 986

- Location

- Dan Saff!

Have you contacted R-Tech?

There's no point giving advice if your welder is defective.

There's no point giving advice if your welder is defective.

Edwardbear

Member

- Messages

- 62

- Location

- Peterborough

What do you thinks wrong with it. It's welding

T0rnado69

DIY nut !!

- Messages

- 1,885

- Location

- Essex

I don't really like the way you've fitted the welder into the trolley.

or having to lump the bottle out the cage when it needs changing.

and im sure they are plated steel.

would be worth a fair bit if completely stainless steel.

thats would be a lot of SS for a £1

Edwardbear

Member

- Messages

- 62

- Location

- Peterborough

That is the only problem with the design. But I'm a thin strong lad so ill be fine. I did consider putting a hinge on the bottle part for easy removal but lack of hinge prompted a change of plan

Swift&Bold

Member

- Messages

- 986

- Location

- Dan Saff!

What do you thinks wrong with it. It's welding

I have no idea.

You....will....have...to....speak....to....R-Tech.

Edwardbear

Member

- Messages

- 62

- Location

- Peterborough

I'm far too drunk to weld! Maybe tomorrow

Edwardbear

Member

- Messages

- 62

- Location

- Peterborough

Edwardbear

Member

- Messages

- 62

- Location

- Peterborough

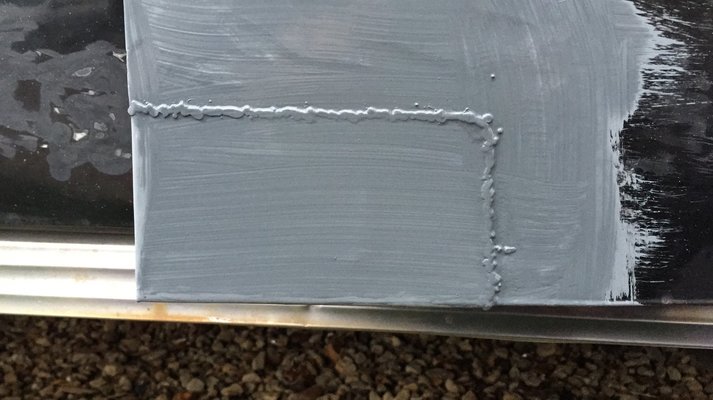

The problem I've got now is that if you look closely you can still see lots of holes. If I weld continuously over it all I'm concerned it will melt holes in it.

Edwardbear

Member

- Messages

- 62

- Location

- Peterborough

How do I get my welds to look less like metal spheres and more like. Is it settings?

Swift&Bold

Member

- Messages

- 986

- Location

- Dan Saff!

A combination of skill, experience, settings, technique and machine.

What did your welding course teach you?

What did your welding course teach you?

Edwardbear

Member

- Messages

- 62

- Location

- Peterborough

It taught me that I can weld bits of 5mm together in a variety of different positions. It didn't however teach me

How to set up my machine

What the different settings mean and how they affect the weld

etc etc

The course basically entailed turning up, the tutor setting up the welder and then saying you doing a lap joint today. I would then practice the lapjoint until it was perfect

The welds above are flatter but also wider than mine, not sure how to achieve this

How to set up my machine

What the different settings mean and how they affect the weld

etc etc

The course basically entailed turning up, the tutor setting up the welder and then saying you doing a lap joint today. I would then practice the lapjoint until it was perfect

The welds above are flatter but also wider than mine, not sure how to achieve this

Edwardbear

Member

- Messages

- 62

- Location

- Peterborough

Edwardbear

Member

- Messages

- 62

- Location

- Peterborough

Did a bit of welding today. Wire tensioner turned up and what a difference. I may turn it up a little more just because it's not quite right but very nearly