You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Welding Band Saw Blade

- Thread starter rtcosic

- Start date

the artfull-codger

Member

- Messages

- 481

- Location

- north yorkshire england

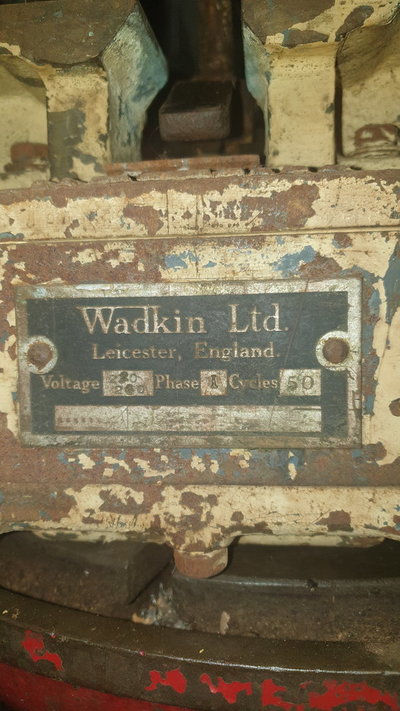

I made a jig to silver braze my blades with a decent scarfed joint using a sievert blowtorch but at an autojumble I got a Wadkin Bursgreen bandsaw brazer, it's 240 volt with automatic paralell clamps & using scarfed joint just press it on for half a minute or so then click to anneal, clean up & job done so brazing is a recognised method of joining as Wadkin don't make rubbish tools.

the artfull-codger

Member

- Messages

- 481

- Location

- north yorkshire england

Hi Jim,yes that's the same one that I have,afraid I've not got a manual for it, but I make a very shallow scarf angle about3/.8" -1/2" long so there's a good area of contact to silver braze,I then mix a liquid easyflow flux with a small dab of washing up liquid & coat the joints & put a piece of silver braze in between if it's round I uusually hammer it flat then put in the jig & press down on number 2 [depending which temp range ] then it melts & switch off keeping it clamoed & your ready to clean itup to thickness you can put it on higher to anneal it but I dont bother hope this helps.HI Artfull Codger, I too have a Wadkin bandsaw brazer. Would you have the operators manual for this or know the procedure for it's use.

thanks you Jim.

View attachment 424777 View attachment 424778 View attachment 424779 View attachment 424781

DAPPH

as dyslexik as I'm daft

- Messages

- 7,181

- Location

- Near to Cross Hands Llanelli SouthWales GB

Was at Fizzy's unit this afternoon cutting some wood for him , I'd just taken the cut stock off the table , turned &started putting it in a big dumpy bag when one hell of a loud crack/ bang occurred , as loud and sharp as a high velocity rifle being fired a few inches from an un protected ear .

I had massive " Botty butterfly's" for a millisecond then realised the 15 foot or so blade on his Grand Daddy Startrite had parted under tension . took several minutes for my heart to get back to a regular useful pattern . The taper roller bearing on the drive & guide wheels are good it must have taken 3 min or more for the freed wheels to stop turning .

Due to the design of the machine a new coarse pure wood cutting blade was quickly put on and sawing wood resumed . It's a mean new wood blade , it cuts through 4x4 pine battens in about four seconds flat .

I had massive " Botty butterfly's" for a millisecond then realised the 15 foot or so blade on his Grand Daddy Startrite had parted under tension . took several minutes for my heart to get back to a regular useful pattern . The taper roller bearing on the drive & guide wheels are good it must have taken 3 min or more for the freed wheels to stop turning .

Due to the design of the machine a new coarse pure wood cutting blade was quickly put on and sawing wood resumed . It's a mean new wood blade , it cuts through 4x4 pine battens in about four seconds flat .

I am glad it was you and not me - the bang sounded loud enough from the kitchen areaWas at Fizzy's unit this afternoon cutting some wood for him , I'd just taken the cut stock off the table , turned &started putting it in a big dumpy bag when one hell of a loud crack/ bang occurred , as loud and sharp as a high velocity rifle being fired a few inches from an un protected ear .

I had massive " Botty butterfly's" for a millisecond then realised the 15 foot or so blade on his Grand Daddy Startrite had parted under tension . took several minutes for my heart to get back to a regular useful pattern . The taper roller bearing on the drive & guide wheels are good it must have taken 3 min or more for the freed wheels to stop turning .

Due to the design of the machine a new coarse pure wood cutting blade was put on and sawing wood resumed . It's a mean new wood blade , it cuts through 4x4 pine battens in about four seconds flat .

Nice to see the blade didn't come out of the machine. Had a few snap on my 24" startrite but the 36" machine is a giant! Perhaps bandsaws are safer than we give them credit for?

good for fingers then!Was at Fizzy's unit this afternoon cutting some wood for him , I'd just taken the cut stock off the table , turned &started putting it in a big dumpy bag when one hell of a loud crack/ bang occurred , as loud and sharp as a high velocity rifle being fired a few inches from an un protected ear .

I had massive " Botty butterfly's" for a millisecond then realised the 15 foot or so blade on his Grand Daddy Startrite had parted under tension . took several minutes for my heart to get back to a regular useful pattern . The taper roller bearing on the drive & guide wheels are good it must have taken 3 min or more for the freed wheels to stop turning .

Due to the design of the machine a new coarse pure wood cutting blade was quickly put on and sawing wood resumed . It's a mean new wood blade , it cuts through 4x4 pine battens in about four seconds flat .