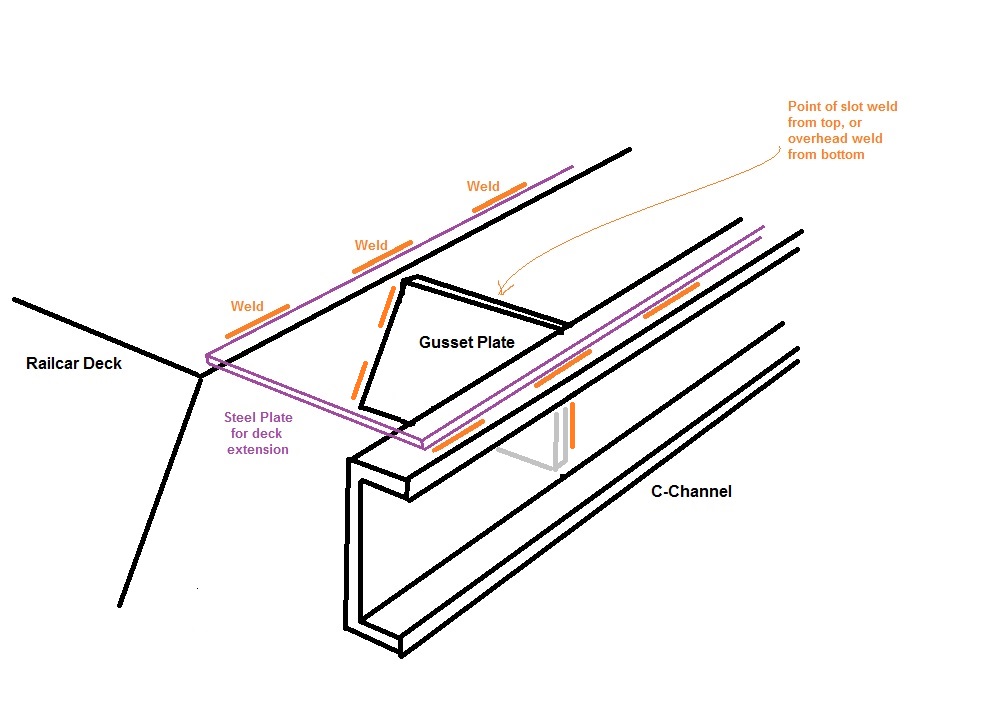

Thank you for all the responses. I apologize for any confusion, but gaz1's middle diagram is in fact what we are doing (see my quick sketch below). I-beam sections instead of gusset plates were not an easy option as the side sill of the rail car is sloped and not perfectly plumb. The broker selling the rail cars has done this many times and provided the design for deck extensions based on what he has done for the rail car bridges he's been manufacturing for around twenty years. The area in question for slot welding is not a critical joint, but we nevertheless want to do it right and not compromise the integrity of the deck extension. Also the welder is proposing to burn the slots not grind them (he would only use the grinder to make them smooth again once finished).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which is more efficient?

- Thread starter Riverland

- Start date

gaz1

Member

- Messages

- 20,526

- Location

- westyorkshire

Gusset plate is 1/2" thick, 14" tall, 14" deep at the bottom and roughly 9-5/8" deep at the top. The C-channel is 12" deep and will be welded along its height to the end of the gusset plate. Gusset plates are spaced every 5'. Not sure I understand your question about supporting the u-channel or letting them hang?