johnrev

Member

- Messages

- 227

- Location

- Norfolk, UK

Congratulations on all you've done so far. I have done similar mods myself to several machines and the wire speed mod really does make a big difference. Only thing I had to do was add a couple of resistors to each end of the PWM board potentiometer to get the useful wire speed range more evenly spread over the pot travel as otherwise the useful range came in about 25% of it's travel as you have found. I'm sure Eddie could advise if you wanted to give this a try.

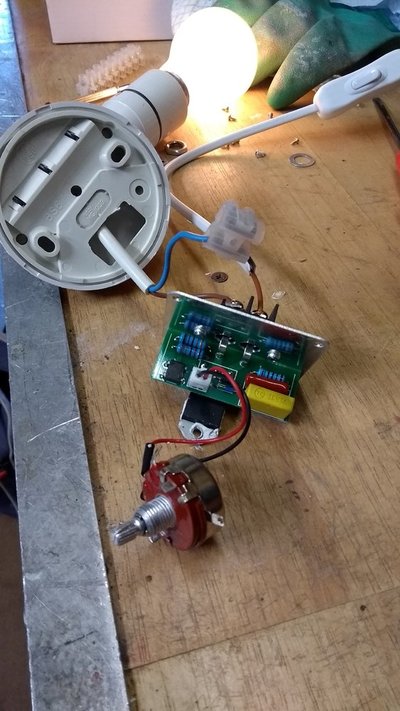

The dimmer I used on my experimental setup was a 10000w unit I bought from Banggood.

Unfortunately I haven't had the spare time to make much use of it but I can say that it does work to control the transformer output voltage as it should. At low setting it sounded very buzzy but slightly off minimum it was fine and control up to max seemed smooth. As Eddie said these are not intended for inductive loads which is why I went for the one with the max power capability I could find. I also noticed it seems to have a rectifier on the board and have seen a youtube vid by 'the post apocolyptic inventor' where he explains the advantage of this. I can't pretend I understood all he said but it sounded like it might help with inductive loads.

The unit I got is:-https://www.banggood.com/AC-220V-10000W-Digital-Control-SCR-Electronic-Voltage-Regulator-Speed-Control-Dimmer-Thermostat-p-1373125.html?rmmds=myorder&cur_warehouse=CN

I have tried adding caps to both a stick welder and mig welder and have been disappointed with the outcome on both machines. All it seemed to do was make a lot more spatter and a horrible crack when striking the arc. Given the time I will try again but the choke is a far more effective method of smoothing an arc as far as I can see so will not worry too much about caps for now.

It's been good to read your progress reports and I'm glad you've had success. All those who say get rid of the machine and get a better one are missing out on a great feeling of achievement when all the head scratching and fettling produces worhwhile results.

All the best

John

The dimmer I used on my experimental setup was a 10000w unit I bought from Banggood.

Unfortunately I haven't had the spare time to make much use of it but I can say that it does work to control the transformer output voltage as it should. At low setting it sounded very buzzy but slightly off minimum it was fine and control up to max seemed smooth. As Eddie said these are not intended for inductive loads which is why I went for the one with the max power capability I could find. I also noticed it seems to have a rectifier on the board and have seen a youtube vid by 'the post apocolyptic inventor' where he explains the advantage of this. I can't pretend I understood all he said but it sounded like it might help with inductive loads.

The unit I got is:-https://www.banggood.com/AC-220V-10000W-Digital-Control-SCR-Electronic-Voltage-Regulator-Speed-Control-Dimmer-Thermostat-p-1373125.html?rmmds=myorder&cur_warehouse=CN

I have tried adding caps to both a stick welder and mig welder and have been disappointed with the outcome on both machines. All it seemed to do was make a lot more spatter and a horrible crack when striking the arc. Given the time I will try again but the choke is a far more effective method of smoothing an arc as far as I can see so will not worry too much about caps for now.

It's been good to read your progress reports and I'm glad you've had success. All those who say get rid of the machine and get a better one are missing out on a great feeling of achievement when all the head scratching and fettling produces worhwhile results.

All the best

John