You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Workbench

- Thread starter ChrisBailey

- Start date

ChrisBailey

Member

- Messages

- 296

- Location

- Kings Lynn, Norfolk, UK

The compressor is too big to move. Its also wired directly into a 40amp supply.

I think i will go for a thicker top, say 5mm.

Ill get a quote for some box too.

I need to be conviced that angle wouldnt be up to the job though, im not bothered about the aesthetics.

I think i will go for a thicker top, say 5mm.

Ill get a quote for some box too.

I need to be conviced that angle wouldnt be up to the job though, im not bothered about the aesthetics.

up to the job of what , cutting 5mm , it will , a nine inch with laser discs will cut 5mm no prob , if you go slowly and dont let the blade flex as they tend to try to do , if you put a guide line on it with a 4 1/2 inch first it will be a lot easier if your not comfy with a 9 inch .. secret is to let the machine do the utting and not be tempted to put pressure on the blade , as they wear out very quickly and tend to wander if you do that ,, or you could clamp or tack a bit of angle on and cut down it using the edge to keep you straight.The compressor is too big to move. Its also wired directly into a 40amp supply.

I think i will go for a thicker top, say 5mm.

Ill get a quote for some box too.

I need to be conviced that angle wouldnt be up to the job though, im not bothered about the aesthetics.

ChrisBailey

Member

- Messages

- 296

- Location

- Kings Lynn, Norfolk, UK

I meant angle steel vs box

If you look closely in the background is the start of a bench made from a left over bit of a lorry chassis , and off cuts from the job in hand,, Ignore the door made out of round bails of course , but just to show it does make a start obviously a longer bit would suit some folk better , but that was the left over part I had from a bigger bit I bought to lengthen a lorry chassis

I meant angle steel vs box

ah sorry , a grinder will cut either , mark round it with a square and welders chalk , then just cut each side and roll it over , box is basically only two bits of angle.

Memmeddu

Member

- Messages

- 4,753

- Location

- Italia Sardegna

First One is from a great Vietnamese channeli rather like these

welding table and plasma table

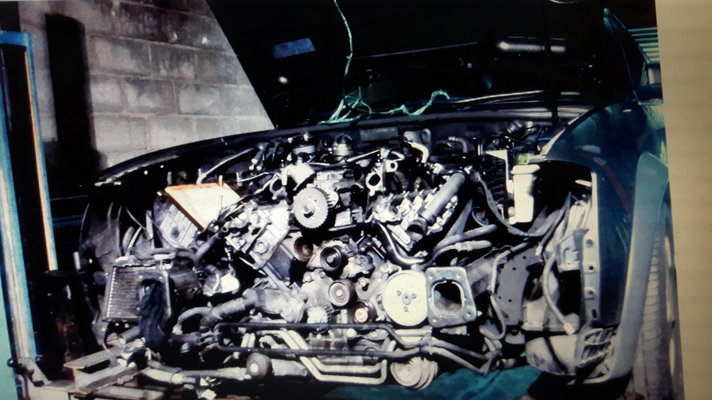

a few odds and ends of what i do , just random pics off my phone as mentioned earlier , i tend not to carry my phone when im working , so ,

a series land rover I did the tin on last year , guy did it for his wife , she drove it once and hated it

the rolls was a favour but did the tins on it

behind the blue series is an orange pick up , it was a td5 disco 2 now a defender 300 tdi tipper , disco chassis with all defender out riggers and engine mounts etc shortened and a defender x member in it , beside it is another of my repaired bulk heads ,

two 90s in the shed are full galv chassis restorations ,again two more of my bulkheads

the hiab is just to show what a 91 ton hiab actually looks like

the white lorry was parked on a fuel pump in dublin , thats me in the fh pulling it off

the john deer in the mud was there pulling out the little dot further out in the pic , it was a shogun that got bogged , the tractor got bogged , two tides later we went to pull it out with the old ford , thats a 30 ton winch on the back and a 12 ton on the front , I put them there .

That sums up just the odds and ends off my phone , hope that helps give some background.

a series land rover I did the tin on last year , guy did it for his wife , she drove it once and hated it

the rolls was a favour but did the tins on it

behind the blue series is an orange pick up , it was a td5 disco 2 now a defender 300 tdi tipper , disco chassis with all defender out riggers and engine mounts etc shortened and a defender x member in it , beside it is another of my repaired bulk heads ,

two 90s in the shed are full galv chassis restorations ,again two more of my bulkheads

the hiab is just to show what a 91 ton hiab actually looks like

the white lorry was parked on a fuel pump in dublin , thats me in the fh pulling it off

the john deer in the mud was there pulling out the little dot further out in the pic , it was a shogun that got bogged , the tractor got bogged , two tides later we went to pull it out with the old ford , thats a 30 ton winch on the back and a 12 ton on the front , I put them there .

That sums up just the odds and ends off my phone , hope that helps give some background.

-

20190822_132001.jpg427.3 KB · Views: 71

20190822_132001.jpg427.3 KB · Views: 71 -

20190822_131855.jpg487 KB · Views: 61

20190822_131855.jpg487 KB · Views: 61 -

Bus-plunges-into-the-sea-and-is-salvaged-by-a-giant-crane (2).jpg87 KB · Views: 66

Bus-plunges-into-the-sea-and-is-salvaged-by-a-giant-crane (2).jpg87 KB · Views: 66 -

20180503_194234.jpg424.3 KB · Views: 63

20180503_194234.jpg424.3 KB · Views: 63 -

20180503_193618.jpg487.4 KB · Views: 65

20180503_193618.jpg487.4 KB · Views: 65 -

20181112_134736.jpg391.3 KB · Views: 66

20181112_134736.jpg391.3 KB · Views: 66 -

IMG-20190511-WA0001.jpg235.4 KB · Views: 59

IMG-20190511-WA0001.jpg235.4 KB · Views: 59 -

IMG-20190511-WA0000.jpg138 KB · Views: 62

IMG-20190511-WA0000.jpg138 KB · Views: 62 -

20190403_144632_1.jpg588.2 KB · Views: 62

20190403_144632_1.jpg588.2 KB · Views: 62 -

20190510_191533.jpg307 KB · Views: 71

20190510_191533.jpg307 KB · Views: 71

anything else interesting , new rear x member in a disco

a buell front end into my old sportster , rode it 12 feet and hated it , sold straight after that

and the recovery truck I usually drive sitting in front of one of the sheds I work in if you look inside you can just about make out another of my cab restoration jobs too

,, The previous picture showing the lorry chassis as a bench base , in front of that is a tipping trailer I built , and the whole lot is sitting in a shed that I did all the steel work for the horse shoe frog was for a friends daughter for xmas ,,

,, The previous picture showing the lorry chassis as a bench base , in front of that is a tipping trailer I built , and the whole lot is sitting in a shed that I did all the steel work for the horse shoe frog was for a friends daughter for xmas ,,

a buell front end into my old sportster , rode it 12 feet and hated it , sold straight after that

and the recovery truck I usually drive sitting in front of one of the sheds I work in if you look inside you can just about make out another of my cab restoration jobs too

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

First One is from a great Vietnamese channel

I like Ca Lems Videos aswell, very talented guy and interesting videos

ChrisBailey

Member

- Messages

- 296

- Location

- Kings Lynn, Norfolk, UK

I have a quote for 18m of 40x40x5mm angle, 1000x2000x4mm sheet. It also includes 18m of 20x20x3mm angle and 1000x2000x1.2mm sheet for another project.

Delivered is £203.

I think im going with this as its definitely beefy enough for automotive work.

The other project is some overhead racking for the same garage.

Hoping my begginer skills and a tecarc 181 will be upbto the job.

Delivered is £203.

I think im going with this as its definitely beefy enough for automotive work.

The other project is some overhead racking for the same garage.

Hoping my begginer skills and a tecarc 181 will be upbto the job.

you will be grand ,, take a while drawing it all oyt before you start though ,, things like getting your knees under the bench if you sit at it , and heights for a vise to be comfy if you beat things , or spend more time with a file than a hammer ,,,I have a quote for 18m of 40x40x5mm angle, 1000x2000x4mm sheet. It also includes 18m of 20x20x3mm angle and 1000x2000x1.2mm sheet for another project.

Delivered is £203.

I think im going with this as its definitely beefy enough for automotive work.

The other project is some overhead racking for the same garage.

Hoping my begginer skills and a tecarc 181 will be upbto the job.

RWD3M

Forum Supporter

- Messages

- 3,219

- Location

- Wiltshire, UK

Ooh, I do like a bit of Galv!bugger still not got the two 90s in View attachment 252903

there you go ,,, Now if you want more i can go look on my computer .