Dcal

Member

- Messages

- 4,069

- Location

- Antrim Northern Ireland

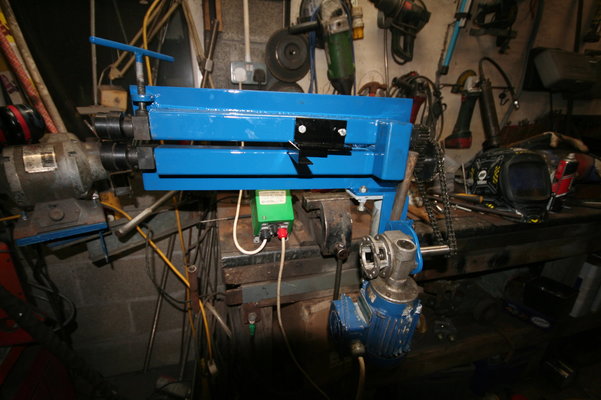

This is my take on modifying a cheap Metz Chinese bead roller

There is a lot of chat on the net on how crap Chinese tools in general are and this bead roller in particular is, but I think they can be quite remarkable value for money and opens up specialist tool ownership to the DIY market.

I think I payed £85 for it on the bay of thieves.

The frame is pretty useless but there is no way you could make the gears and rollers for the money and the lack of substance to the frame gives unlimited scope for modifications without having to remove any stiffening (as there isn't any).

I did not try it out straight out of the box as that seemed pointless (the two rollers could be flexed more than an inch by hand without any bother) but I could see the potential.

For the mods I just used whatever scrap and off cuts I had laying about (don't we all?) and found a piece of 4" x 2" galvanized thin wall box that could be used for most of the strengthening mods.

I wanted to keep the dimensions of the roller as neat as possible so decided to cut the box in half (long ways) and installed each half over a roller drive bar.

To provide a moment connection between the two now 2" x 2" bits of box I welded a section of 2" x 4" box with holes drilled in it to allow the roller drive bars to pass through.

I used tig for the welding (and a lot more than necessary), as I'm trying to learn and I find making something is better practice than just laying down beads on scrap.

I did grind off the galv before I started welding.

Even without the health risks, its bad enough welding it with mig or stick but it's almost impossible if using tig.

Sorry for the long-winded ramble to describe how I got to this

There is a lot of chat on the net on how crap Chinese tools in general are and this bead roller in particular is, but I think they can be quite remarkable value for money and opens up specialist tool ownership to the DIY market.

I think I payed £85 for it on the bay of thieves.

The frame is pretty useless but there is no way you could make the gears and rollers for the money and the lack of substance to the frame gives unlimited scope for modifications without having to remove any stiffening (as there isn't any).

I did not try it out straight out of the box as that seemed pointless (the two rollers could be flexed more than an inch by hand without any bother) but I could see the potential.

For the mods I just used whatever scrap and off cuts I had laying about (don't we all?) and found a piece of 4" x 2" galvanized thin wall box that could be used for most of the strengthening mods.

I wanted to keep the dimensions of the roller as neat as possible so decided to cut the box in half (long ways) and installed each half over a roller drive bar.

To provide a moment connection between the two now 2" x 2" bits of box I welded a section of 2" x 4" box with holes drilled in it to allow the roller drive bars to pass through.

I used tig for the welding (and a lot more than necessary), as I'm trying to learn and I find making something is better practice than just laying down beads on scrap.

I did grind off the galv before I started welding.

Even without the health risks, its bad enough welding it with mig or stick but it's almost impossible if using tig.

Sorry for the long-winded ramble to describe how I got to this

) and I don't think the hole drilled exactly in the center (I just used a blacksmiths drill bit and think it wondered off a bit) but again good enough for the speed involved.

) and I don't think the hole drilled exactly in the center (I just used a blacksmiths drill bit and think it wondered off a bit) but again good enough for the speed involved.