Dcal

Member

- Messages

- 4,079

- Location

- Antrim Northern Ireland

Bit of an update.

I can confirm that a ball joint boot works very well and although they are a different design I think they are better than the original.

I got them on ebay for not much (19 x 28 x 16 if the link doesn't work)

To install the boot, I needed to make a puller to remove the alignment bush.

And a punch to reinstall the alignment bush after the boot and rubber coupler was fitted.

Before I can go any further with this I want to install the prop and check for runout, (I don't want to get it balanced and find it's assembled incorrectly) but before I can do that I need to install the engine and gear box and before I do that I wanted to clean up the alloy bellhousing and to do that I needed (of course) to make a vapour blaster.

So for now the checking of the alignment and balance of the prop is stalled and I've started on another project that will probably not get finished either.

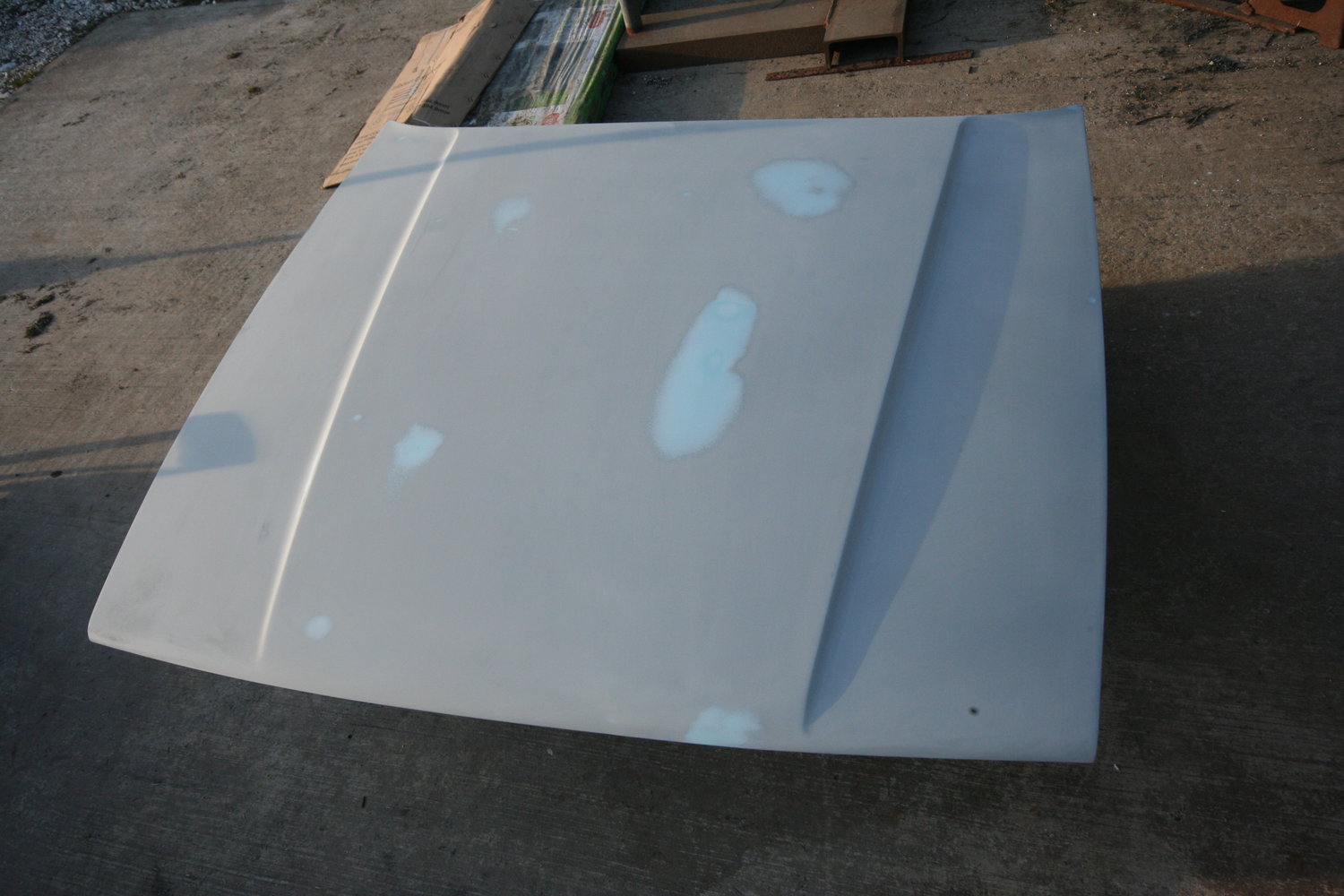

I worked on a few other jobs on the list, like undercoating the bonnet.

Because of the state of it I use the Jotun 90 as a high build primer sealer.

It's not recommended for that application but it works for me. It is harder to sand than most other primers but I think it's worth the effort for the protection it provides.

It goes on a bit "peely" but that’s ok because most of it will be sanded off anyway.

The intention was to leave this a couple of weeks before sanding to make sure it was well cured.

To make room for the Vapour Blaster Project, I moved the bonnet outside and hung it on a frame.

Of course the inevitable happened and a gust of wind blew it over and as a result I'm further back than ever with 3 or 4 nice dents to beat out.

I didn't take photos because I was too busy saying bad words.

I huffed for a while but eventually I got the bog out and fixed them.

I also filled the front wing I welded longer ago than I care to remember.

I gave them the Jotun treatment with a few other bits and hopefully I won't drop them again.

Also removed the rack and installed new track rods, trackrod ends and boots so another job off the list.

I can confirm that a ball joint boot works very well and although they are a different design I think they are better than the original.

I got them on ebay for not much (19 x 28 x 16 if the link doesn't work)

Ball joint rubber boot dust cover universal 2 x 19x28x16 track rod end Car Van | eBay

Find many great new & used options and get the best deals for Ball joint rubber boot dust cover universal 2 x 19x28x16 track rod end Car Van at the best online prices at eBay! Free delivery for many products.

www.ebay.co.uk

To install the boot, I needed to make a puller to remove the alignment bush.

And a punch to reinstall the alignment bush after the boot and rubber coupler was fitted.

Before I can go any further with this I want to install the prop and check for runout, (I don't want to get it balanced and find it's assembled incorrectly) but before I can do that I need to install the engine and gear box and before I do that I wanted to clean up the alloy bellhousing and to do that I needed (of course) to make a vapour blaster.

So for now the checking of the alignment and balance of the prop is stalled and I've started on another project that will probably not get finished either.

I worked on a few other jobs on the list, like undercoating the bonnet.

Because of the state of it I use the Jotun 90 as a high build primer sealer.

It's not recommended for that application but it works for me. It is harder to sand than most other primers but I think it's worth the effort for the protection it provides.

It goes on a bit "peely" but that’s ok because most of it will be sanded off anyway.

The intention was to leave this a couple of weeks before sanding to make sure it was well cured.

To make room for the Vapour Blaster Project, I moved the bonnet outside and hung it on a frame.

Of course the inevitable happened and a gust of wind blew it over and as a result I'm further back than ever with 3 or 4 nice dents to beat out.

I didn't take photos because I was too busy saying bad words.

I huffed for a while but eventually I got the bog out and fixed them.

I also filled the front wing I welded longer ago than I care to remember.

I gave them the Jotun treatment with a few other bits and hopefully I won't drop them again.

Also removed the rack and installed new track rods, trackrod ends and boots so another job off the list.