You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

25 year old Alfa 75 back from the brink (hopefully)

- Thread starter Dcal

- Start date

Dcal

Member

- Messages

- 3,972

- Location

- Antrim Northern Ireland

Thanks Exuptoy, starting to see the end of the welding now but was really p****d off that I didn't get more done over the Christmas break.

With everything stripped out was glad I removed the screen as the screen surround is pretty scabby in places.

First job was the rot at the bonnet hinges.

Again it's in holes but doesn't extend too far.

Started by cutting from the inside at the underside of the dash

Then from the top side.

First patch.

Then the others and weld them in.

Then tack in the underside.

Before finishing it off and grinding the welds.

And finishing off the repair into the inner guard area

Finished repair from the dash side.

With everything stripped out was glad I removed the screen as the screen surround is pretty scabby in places.

First job was the rot at the bonnet hinges.

Again it's in holes but doesn't extend too far.

Started by cutting from the inside at the underside of the dash

Then from the top side.

First patch.

Then the others and weld them in.

Then tack in the underside.

Before finishing it off and grinding the welds.

And finishing off the repair into the inner guard area

Finished repair from the dash side.

Dieselman 63

Forklift Certified

- Messages

- 5,681

- Location

- Wellington, New Zealand

Thanks Exuptoy, starting to see the end of the welding now but was really p****d off that I didn't get more done over the Christmas break.

With everything stripped out was glad I removed the screen as the screen surround is pretty scabby in places.

First job was the rot at the bonnet hinges.

Again it's in holes but doesn't extend too far.

Started by cutting from the inside at the underside of the dash

View attachment 165050

Then from the top side.

View attachment 165051

First patch.

View attachment 165052

Then the others and weld them in.

View attachment 165053

Then tack in the underside.

View attachment 165054

Before finishing it off and grinding the welds.

View attachment 165055

And finishing off the repair into the inner guard area

View attachment 165056

Finished repair from the dash side.

View attachment 165057

End of the welding? So we might get to see some paint going on soon?

Dcal

Member

- Messages

- 3,972

- Location

- Antrim Northern Ireland

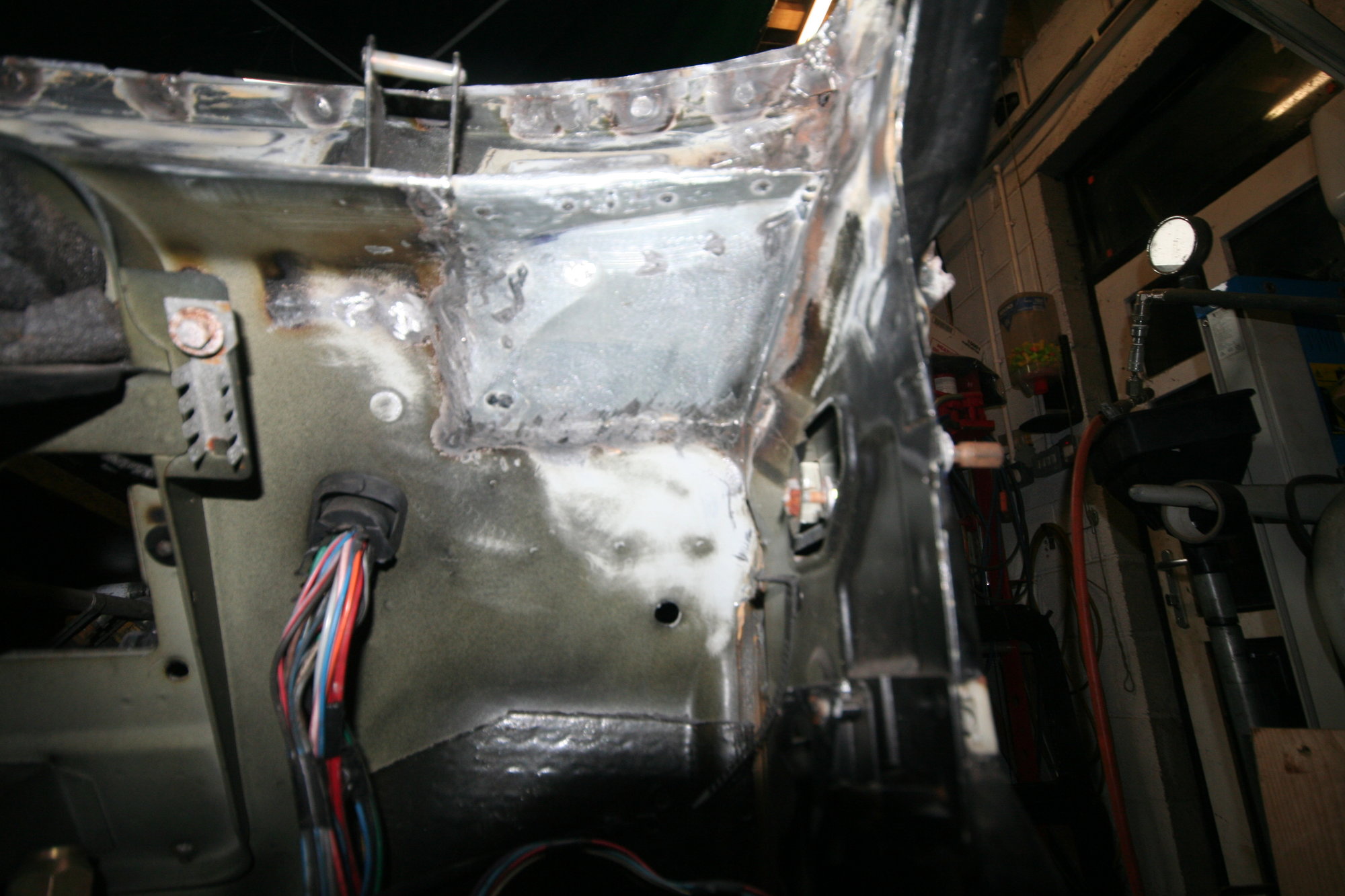

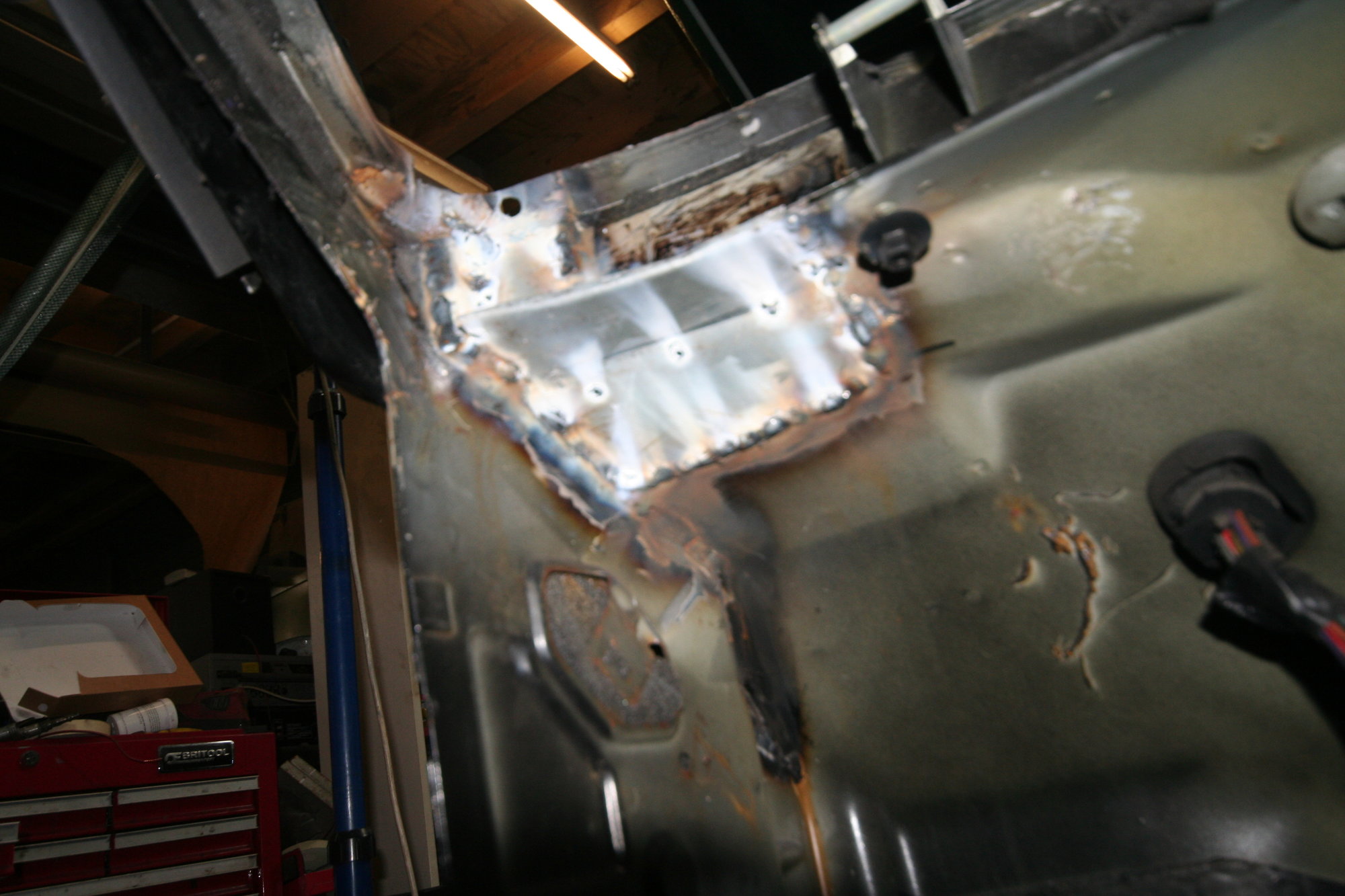

Passenger side next, which was basically the same only worse.

Few pics of the before, during, after and the additional work required.

From the engine bay

From the dash

From the inner guard

And after removing the strengthening plate and opening it up a bit.

After patching from the engine bay.

And from the inside

Bit of a clean up, spot blast and weld through primer to the inner guard area.

Make and install another patch

To make the dies to punch the hole in the final patch required, I was going to just plasma them out of a bit of plate but my Draper "Expert" plasma went pop so I has to drill and file them instead.

Same result just takes longer.

Then just clean it all up, put it back together and grind the welds back.

Few pics of the before, during, after and the additional work required.

From the engine bay

From the dash

From the inner guard

And after removing the strengthening plate and opening it up a bit.

After patching from the engine bay.

And from the inside

Bit of a clean up, spot blast and weld through primer to the inner guard area.

Make and install another patch

To make the dies to punch the hole in the final patch required, I was going to just plasma them out of a bit of plate but my Draper "Expert" plasma went pop so I has to drill and file them instead.

Same result just takes longer.

Then just clean it all up, put it back together and grind the welds back.

Dcal

Member

- Messages

- 3,972

- Location

- Antrim Northern Ireland

Thanks @Exuptoy

You've been quiet on the project front recently, have you anything on the go?

With the corners finished next was the bit that normally goes on these Alfa's, the heater air intake vents.

As @bricol has said the drain pipe clogs and water get trapped in the area until it rots through to the cabin.

With everything stripped out access is pretty good but the patches required are all awkward shapes.

First job was to repair the closure panel

I then cut out the rot in the bulk head and made a patch.

And welded it in. I needed to re-weld the dash brackets that came out with the patch but were in good shape.

Next is the small panel that holds the air intake vent

Then spot blast and clean up the panels

And start to put it back together

You've been quiet on the project front recently, have you anything on the go?

With the corners finished next was the bit that normally goes on these Alfa's, the heater air intake vents.

As @bricol has said the drain pipe clogs and water get trapped in the area until it rots through to the cabin.

With everything stripped out access is pretty good but the patches required are all awkward shapes.

First job was to repair the closure panel

I then cut out the rot in the bulk head and made a patch.

And welded it in. I needed to re-weld the dash brackets that came out with the patch but were in good shape.

Next is the small panel that holds the air intake vent

Then spot blast and clean up the panels

And start to put it back together

Exuptoy

Member

- Messages

- 2,931

- Location

- Maesteg, South Wales

Fella, I can turn my hand to fabrication but I would be lost here! You are putting stuff back which you can't even measure as there is nothing left!!

Amazed as usual mate.

The bus is back on the back burner and I haven't done anything in quite a while, however I have just picked up a 600 Suzuki Bandit which needs a bit of love and a gentle recommission. For me, bikes are where its at. I still need my second garage built so I can get the bike stuff out and I'll then have a dedicated garage to get into the T2 so maybe this year???

Anyway, I can get my fix watching you guys. I love it reading these threads. Carry on my friend.

Amazed as usual mate.

The bus is back on the back burner and I haven't done anything in quite a while, however I have just picked up a 600 Suzuki Bandit which needs a bit of love and a gentle recommission. For me, bikes are where its at. I still need my second garage built so I can get the bike stuff out and I'll then have a dedicated garage to get into the T2 so maybe this year???

Anyway, I can get my fix watching you guys. I love it reading these threads. Carry on my friend.

Dcal

Member

- Messages

- 3,972

- Location

- Antrim Northern Ireland

@Exuptoy I never got into bikes which is probably just as well. With my ego and lack of skill I would probably have been wiped out long ago.

It's harder (but not impossible) to fall off a car.

Bit more on the bulkhead repair.

Scuttle panel needed a few small patches.

It wouldn't fit in the blast cabinet so gave the crusty bits a going over with the spot blaster

I connect it up to a vacuum and a cyclone separator (pretty much the same as the one in @Burdekin thread) so I can reuse the grit.

With it patches sorted I ground the welds back and welded it back into place

While I was at it I sorted the rot in the windscreen surround

Spot blasted the scabby bits and welded or patched the really bad bits

Then get it covered with a bit of epoxy

Yhe bits that wont be seen at all I did with a couple of coats of Jotan 87A with a brush

When that had gone off I sprayed the rest with Sherwin Williams 2K epoxy

It's harder (but not impossible) to fall off a car.

Bit more on the bulkhead repair.

Scuttle panel needed a few small patches.

It wouldn't fit in the blast cabinet so gave the crusty bits a going over with the spot blaster

I connect it up to a vacuum and a cyclone separator (pretty much the same as the one in @Burdekin thread) so I can reuse the grit.

With it patches sorted I ground the welds back and welded it back into place

While I was at it I sorted the rot in the windscreen surround

Spot blasted the scabby bits and welded or patched the really bad bits

Then get it covered with a bit of epoxy

Yhe bits that wont be seen at all I did with a couple of coats of Jotan 87A with a brush

When that had gone off I sprayed the rest with Sherwin Williams 2K epoxy

Dcal

Member

- Messages

- 3,972

- Location

- Antrim Northern Ireland

Got another tiny bit done and it shows why these jobs always take me longer than I think.

Starting to think about getting all the panels back on so I can line everything up and check if any of the panels need tweaked. (The DS front wing certainly will as I dropped it and gave it a nasty ding!)

The bottom half of the rear PS door window channel was crusty.

I could have spent a silly amount of time on the internet trying to get a better second hand one so though I'd have a go at fixing it.

Started off by drawing around the channel so I don't lose the shape

Then made two tiny channel sections out of 1mm steel to form the outsides of the section

I had to make the "flanges" longer than necessary, just to be able to fold them, then cut them back with a 4 inch angle grinder.

I then cut the web using the original channel as a template.

I used a bit of thicker flat bar to keep the "web" from twisting while I tacked it up.

With it tacked up I lined up the other flange and clamped it using the vice, vice grips and g-clamps.

The "web" is offset so easy to mess up here.

I could then braze it all up and surprisingly it didn't warp too much.

With that done I was able to cut the bad bit out and set in the new section, then remove the mounting brackets from the old one and fit to the new.

The repair wasn't a perfect fit so just filled it out with brass and faired it in

A quick blast some epoxy, then filler and another lick of epoxy and it doesn't look too shabby.

Not perfect but good enough as most of it is inside the door.

The window rubbers will hide where I went off with the grinder.

Starting to think about getting all the panels back on so I can line everything up and check if any of the panels need tweaked. (The DS front wing certainly will as I dropped it and gave it a nasty ding!)

The bottom half of the rear PS door window channel was crusty.

I could have spent a silly amount of time on the internet trying to get a better second hand one so though I'd have a go at fixing it.

Started off by drawing around the channel so I don't lose the shape

Then made two tiny channel sections out of 1mm steel to form the outsides of the section

I had to make the "flanges" longer than necessary, just to be able to fold them, then cut them back with a 4 inch angle grinder.

I then cut the web using the original channel as a template.

I used a bit of thicker flat bar to keep the "web" from twisting while I tacked it up.

With it tacked up I lined up the other flange and clamped it using the vice, vice grips and g-clamps.

The "web" is offset so easy to mess up here.

I could then braze it all up and surprisingly it didn't warp too much.

With that done I was able to cut the bad bit out and set in the new section, then remove the mounting brackets from the old one and fit to the new.

The repair wasn't a perfect fit so just filled it out with brass and faired it in

A quick blast some epoxy, then filler and another lick of epoxy and it doesn't look too shabby.

Not perfect but good enough as most of it is inside the door.

The window rubbers will hide where I went off with the grinder.

Dcal

Member

- Messages

- 3,972

- Location

- Antrim Northern Ireland

Thanks Exuptoy,

Its a bit silly how long this sort of think takes and can you imaging what it would cost if you had to pay (or charge) someone for fixing it!

Fortunately I'm not counting the hours and really do enjoy the process of repairing something rather than just heading for the shops. (Even if there is a shop where I could get it)

The brazing worked great, much better than I expected.

If I had used Mig or Tig I think it would have been a mess and required a shed load of grinding.

I hope the flux got all removed when I blasted it but you never know.

Its a bit silly how long this sort of think takes and can you imaging what it would cost if you had to pay (or charge) someone for fixing it!

Fortunately I'm not counting the hours and really do enjoy the process of repairing something rather than just heading for the shops. (Even if there is a shop where I could get it)

The brazing worked great, much better than I expected.

If I had used Mig or Tig I think it would have been a mess and required a shed load of grinding.

I hope the flux got all removed when I blasted it but you never know.

Dieselman 63

Forklift Certified

- Messages

- 5,681

- Location

- Wellington, New Zealand

Thanks Exuptoy,

Its a bit silly how long this sort of think takes and can you imaging what it would cost if you had to pay (or charge) someone for fixing it!

Fortunately I'm not counting the hours and really do enjoy the process of repairing something rather than just heading for the shops. (Even if there is a shop where I could get it)

The brazing worked great, much better than I expected.

If I had used Mig or Tig I think it would have been a mess and required a shed load of grinding.

I hope the flux got all removed when I blasted it but you never know.

I know someone with a Maserati BiTurbo which is in a similar state of repair. There’s a lot of work and a lot of money involved in getting it roadworthy - he doesn’t do the repairs himself! Either way though it’s nice to see these old cars kept going, I love the eighties body shapes

Dcal

Member

- Messages

- 3,972

- Location

- Antrim Northern Ireland

I've a mate that wanted something to fix-up so he bought a 205gti project. He was talking about getting a XR2 but I talked him out of that.

He said he wanted something to work at it himself.

I gave him a hand to put it together and get a years MOT on it and told him to enjoy it for a while.

A few weeks later he ended up getting someone to completely gut and overhaul everything.

It been off the road for 4 years, he must be £20K in and its still not finished.

Don't think he will ever get his money out of it.

He said he wanted something to work at it himself.

I gave him a hand to put it together and get a years MOT on it and told him to enjoy it for a while.

A few weeks later he ended up getting someone to completely gut and overhaul everything.

It been off the road for 4 years, he must be £20K in and its still not finished.

Don't think he will ever get his money out of it.

dobbslc

Member

- Messages

- 12,227

- Location

- Hertfordshire UK

"It's harder (but not impossible) to fall off a car."

You are correct as I proved once by "falling off" my mates Marina in a pub carpark, (where else )

)

They had locked me out so I put my elbow in the open passenger window crouched down and held on, he got it into second gear before I decided to bail out as my feet were getting hot from the friction on the tarmac.......

Minor cuts and bruises helped by the 6 pints of Lowenbrau aesthetic.

Great work on that old Alfa BTW!

You are correct as I proved once by "falling off" my mates Marina in a pub carpark, (where else

)

)They had locked me out so I put my elbow in the open passenger window crouched down and held on, he got it into second gear before I decided to bail out as my feet were getting hot from the friction on the tarmac.......

Minor cuts and bruises helped by the 6 pints of Lowenbrau aesthetic.

Great work on that old Alfa BTW!

Dcal

Member

- Messages

- 3,972

- Location

- Antrim Northern Ireland

"It's harder (but not impossible) to fall off a car."

You are correct as I proved once by "falling off" my mates Marina in a pub carpark, (where else)

They had locked me out so I put my elbow in the open passenger window crouched down and held on, he got it into second gear before I decided to bail out as my feet were getting hot from the friction on the tarmac.......

Great times

I served my time on Marinas and Minis when I was an apprentice motor vehicle technician with the post office (and BT)

It was great learning (working on everything from chain saws to Arctics) but I remember having to do a safety check every 1500 miles and a service every 3000 miles.

If an engine lasted 50,000 miles we had a party.

How things have changed

Dcal

Member

- Messages

- 3,972

- Location

- Antrim Northern Ireland

Welding isn't finished yet, but to kid myself I'm making progress decided to work on trying to get some bits of the bodywork in primer.

Easy bits was the inside of the dash and the front jacking points.

First job was to remove all the sound deadening from behind the dash

Then a coat of Jotan 87A

Then seam seal and another coat of Jotan and a brush coat of black

After that lot dried I was able to apply the sound-deading back on to the bits removed for repair.

Before i could finish the DS floor area, you guessed it, I needed another patch. (The one at the drain hole) I also needed to grind the welds on the jacking point repair.

But got that side finished as well

The PS doors were welded up a long time ago (still need to do the DS) and as I need to hang the doors to get every thing to line up before tweaking the door gaps etc. I decided to fill and prime the door bottoms.

I had already applied a coat of epoxy so I thought I just needed to flat and fill but it's never that simple.

After removing the old sealer form the bottom of the doors I needed to treat and then reapply epoxy before applying the seam sealer.

The seam sealer is tricky to get right without a bit of practice but it turned out ok.

I trimmed off the edges after the sealer dried

Then it's on with the plop

Before more epoxy primer

Note the dust on Farecla guide coat (that I will never use again) it just clogs the sandpaper and puts a black soot type substance everywhere.

It's supposed to be quick and you don't need to wait for it to dry, but that because it never dries!

Still you have to try these things, but I'll stick with a proper guide coat paint.

Easy bits was the inside of the dash and the front jacking points.

First job was to remove all the sound deadening from behind the dash

Then a coat of Jotan 87A

Then seam seal and another coat of Jotan and a brush coat of black

After that lot dried I was able to apply the sound-deading back on to the bits removed for repair.

Before i could finish the DS floor area, you guessed it, I needed another patch. (The one at the drain hole) I also needed to grind the welds on the jacking point repair.

But got that side finished as well

The PS doors were welded up a long time ago (still need to do the DS) and as I need to hang the doors to get every thing to line up before tweaking the door gaps etc. I decided to fill and prime the door bottoms.

I had already applied a coat of epoxy so I thought I just needed to flat and fill but it's never that simple.

After removing the old sealer form the bottom of the doors I needed to treat and then reapply epoxy before applying the seam sealer.

The seam sealer is tricky to get right without a bit of practice but it turned out ok.

I trimmed off the edges after the sealer dried

Then it's on with the plop

Before more epoxy primer

Note the dust on Farecla guide coat (that I will never use again) it just clogs the sandpaper and puts a black soot type substance everywhere.

It's supposed to be quick and you don't need to wait for it to dry, but that because it never dries!

Still you have to try these things, but I'll stick with a proper guide coat paint.

Dieselman 63

Forklift Certified

- Messages

- 5,681

- Location

- Wellington, New Zealand

When I’m working on my (many) iron toys, if I take them back to bare metal I always prime, even if I’ll be stripping paint beside the bit I just did, you just want that protection on the metal to stop it oxidising. As ever, I’m greatly impressed with this build.

I'll say it again - be careful with the epoxy primer. The instructions say to blast or abrade to give it sufficient key - and that is my long term experience (10yrs) of using it. Sticks like the proverbial ****e to a blanket where its blasted - and comes off in flakes where not.

Exuptoy

Member

- Messages

- 2,931

- Location

- Maesteg, South Wales

Amazed.com once again! Lovely job. I use 1-2-1 epoxy mastic from Rustbuster and it is a superb product, never had an issue. What a couple of guys on the VW T2 forums tend to do is mix up enough then any left over pour it into the door skins and cavities so it stops the oxygen and moisture getting between the skins and stops them starting to rust. A nice idea I think.