- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A vfd for my lathe

- Thread starter Carl Wilson

- Start date

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray

Yes on balance I'd agree. The change wheels had altogether too much backlash in them. After I adjusted them the back end was much quieter. The only appreciable noise then was coming from the link belt - a sort of rattle.

Now that the rubber belts are on the rattle has gone. It's hard to be objective though - I'm conscious of wanting the thing to be quieter. So I put it here to get some unbiased opinions. I'm apt to think it is quieter now, so thanks for confirming.

Alan it was who calculated the belt size; I'd rather roughly just measured the internal circumference of the link belts. My figure matched well with his, so I went ahead and purchased.

I've now got some more parts to continue with the installation so there should be some more updates soon.

Now that the rubber belts are on the rattle has gone. It's hard to be objective though - I'm conscious of wanting the thing to be quieter. So I put it here to get some unbiased opinions. I'm apt to think it is quieter now, so thanks for confirming.

Alan it was who calculated the belt size; I'd rather roughly just measured the internal circumference of the link belts. My figure matched well with his, so I went ahead and purchased.

I've now got some more parts to continue with the installation so there should be some more updates soon.

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray

Thanks for that. I appreciate the need for backlash. I haven't removed it in its entirety. There was far too much. I re adjusted the set up to finesse the mesh of the complete train.

I do tend to give the change wheels a spray with some dry film lubricant, usually Molykote.

I do tend to give the change wheels a spray with some dry film lubricant, usually Molykote.

Can you get a vfd to run a 240 volt motor from 240 volt supply?Hello everyone,

I have decided to fit a vfd to my Harrison M250. The vfd unit I have is a Teco/Westinghouse E510. It is a fairly capable device with lots of programming options. This will be driving a 1.5 kW 240 volt 3ph motor.

My Harrison M250 is a genuine factory single phase model. My plan is to keep the original control panel and use the switches on it to operate the inverter. The existing switch gear will remain in situ, in case I decide to return the lathe to single phase operation in the future. Only the switch contacts will be in circuit with the vfd.

There will be a separate small pendant with the speed control potentiometer on it, along with the jog fwd/rev controls. This is required as there are no switches on the existing control panel that can be pressed into service for these functions.

The vfd and motor are currently fitted to a mill/drill which is the donor machine. I've used this as a test bed to setup the parameters of the vfd the way I want before removing the motor and drive.

I'm using what's called three wire control to switch the motor on and off. This requires a normally open and normally closed push button. This option enables me to use the existing panel switches for on/off.

The fwd/rev input will be connected to the existing rotary switch on the control panel. I have programmed one of the vfd external inputs to give a rapid deceleration to stop. This will be hooked to the series connected safety switches on the lathe chuck guard and change wheel cover, as well as the kick e stop.

This just leaves the jog controls and speed potentiometer. As previously mentioned these will be on a separate pendant. The potentiometer is wired to the vfd's internal 10 volt supply with the wiper feeding one of the two analogue inputs.

Here is the vfd connected up for testing. I'm using microswitches just to get things working prior to transfer to the lathe.

View attachment 125424

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray

Short answer is yes you can.

Slightly longer answer is that the vfd creates a 240 volt three phase supply from a 240 volt single phase one. It does this by rectifying the incoming mains and then converting this Dc back to three phase Ac by high frequency switching using large power transistors.

By varying the frequency the speed of the motor is also varied. The motor really needs to be rated for use with a vfd. This is because the Ac produced is not a true sine wave. It is a pseudo sine wave made up of high frequency chopped square waves. These can send higher voltage spikes to.the motor which the windings must be rated for.

Slightly longer answer is that the vfd creates a 240 volt three phase supply from a 240 volt single phase one. It does this by rectifying the incoming mains and then converting this Dc back to three phase Ac by high frequency switching using large power transistors.

By varying the frequency the speed of the motor is also varied. The motor really needs to be rated for use with a vfd. This is because the Ac produced is not a true sine wave. It is a pseudo sine wave made up of high frequency chopped square waves. These can send higher voltage spikes to.the motor which the windings must be rated for.

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray

That's true to a degree. You must however be careful running standard motors at lower speeds. They will tend to overheat more than a vfd duty unit. This is because of the additional current induced in the rotor bars by the high carrier frequency, which produces next to no torque.

The integrity of the insulation of a standard motor can also be compromised by the voltage spikes mentioned. These would be at the level of the Dc bus, so 1.414 times the Ac line voltage. Of course normally you'd test the insulation at twice the rated voltage.

However, if it's an old motor with slightly ropey insulation to begin with, and this is further exacerbated by overheating, then a breakdown is much more likely. If this is going to happen it'll be at the end turns of the windings.

Another factor to consider is resonance caused by the high frequency carrier. At best this will cause excessive noise and at worst could damage bearings and other components of the motor.

Vfd rated motors are designed to cope with all of this and are not that big an outlay in the scheme of things. If you are going to convert a machine to vfd operation then it is best to purchase a motor that will work well with your chosen unit.

The integrity of the insulation of a standard motor can also be compromised by the voltage spikes mentioned. These would be at the level of the Dc bus, so 1.414 times the Ac line voltage. Of course normally you'd test the insulation at twice the rated voltage.

However, if it's an old motor with slightly ropey insulation to begin with, and this is further exacerbated by overheating, then a breakdown is much more likely. If this is going to happen it'll be at the end turns of the windings.

Another factor to consider is resonance caused by the high frequency carrier. At best this will cause excessive noise and at worst could damage bearings and other components of the motor.

Vfd rated motors are designed to cope with all of this and are not that big an outlay in the scheme of things. If you are going to convert a machine to vfd operation then it is best to purchase a motor that will work well with your chosen unit.

Last edited:

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray

Fair comment. What I should have mentioned was that under certain circumstances these voltage spikes can set up a reflected wave that can double this voltage. Usually happens when motors are placed quite far from the vfd.

There are other things like higher inductance to better smooth the pwm output to a better approximation of a sine wave that these motors have.

I don't really want to get into a huge argument over this. My opinion is, and my advice to others would be that if you intend to convert a machine to vfd operation then the extra expense of buying the correct motor is more than justified if you expect to see any of the benefits associated with using the vfd in the first place.

There are other things like higher inductance to better smooth the pwm output to a better approximation of a sine wave that these motors have.

I don't really want to get into a huge argument over this. My opinion is, and my advice to others would be that if you intend to convert a machine to vfd operation then the extra expense of buying the correct motor is more than justified if you expect to see any of the benefits associated with using the vfd in the first place.

daleyd

Member

- Messages

- 10,552

- Location

- Wrexham, North Wales

I’d agree with Pete, for home use, unless your planning on using it heavily then there’s just no point unless you really want to. If you are refitting a pump or fan in a production critical environment you’d obviously have a different view.

I’ve retrofitted a lot of machines, fans pumps etc with vfd control often with old motors, I’ve only once, maybe twice come across problems and those were the motors that were already on their way out. Don’t forget that also most motors will be rated for 400v operation so by virtue of running them from a 240 source your already reducing the burden on the insulation, irrespective of anything extra caused by the vfd.

Set a decent minimum speed, so you don’t lose cooling, keep an eye on temperatures when you first use it a few times and you’ll probably be fine. You can certainly enjoy all the benefits of a vfd even with very old motors (I’ve got a hoover brand ancient motor that runs just fine off a Siemens single phase inverter)

None of what Carl says is incorrect, it’s just that in my experience it’s not usually an issue (for home use).

I’ve retrofitted a lot of machines, fans pumps etc with vfd control often with old motors, I’ve only once, maybe twice come across problems and those were the motors that were already on their way out. Don’t forget that also most motors will be rated for 400v operation so by virtue of running them from a 240 source your already reducing the burden on the insulation, irrespective of anything extra caused by the vfd.

Set a decent minimum speed, so you don’t lose cooling, keep an eye on temperatures when you first use it a few times and you’ll probably be fine. You can certainly enjoy all the benefits of a vfd even with very old motors (I’ve got a hoover brand ancient motor that runs just fine off a Siemens single phase inverter)

None of what Carl says is incorrect, it’s just that in my experience it’s not usually an issue (for home use).

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray

I'm glad that is the case from experience, which I bow to.

I'm conscious that people read these threads to get information, because I do that myself. So I just wanted to err on the side of caution with regard to recommending what motor to use.

I'm learning new things if nobody else is!

I'm conscious that people read these threads to get information, because I do that myself. So I just wanted to err on the side of caution with regard to recommending what motor to use.

I'm learning new things if nobody else is!

daleyd

Member

- Messages

- 10,552

- Location

- Wrexham, North Wales

Yeah everything you say is perfectly correct but needs to be taken into context.I'm glad that is the case from experience, which I bow to.

I'm conscious that people read these threads to get information, because I do that myself. So I just wanted to err on the side of caution with regard to recommending what motor to use.

I'm learning new things if nobody else is!

If I was installing a vfd for a customer those are exactly the sort of things I’d be saying to them, but for a lathe/drill/mill in a home workshop, it’s just not worth worrying about.

I’ve put vfd on some right shonky old motors (customer wouldn’t pay for replacement) that run 24/7 , or at least a lot more than a home workshop, and they’re still going after years of operation.

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray

No practical updates for a while. I'm away for work again.

A few more bits turned up just before I left. My new isolate switch and some conduit. Slowly but surely.

A few more bits turned up just before I left. My new isolate switch and some conduit. Slowly but surely.

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray

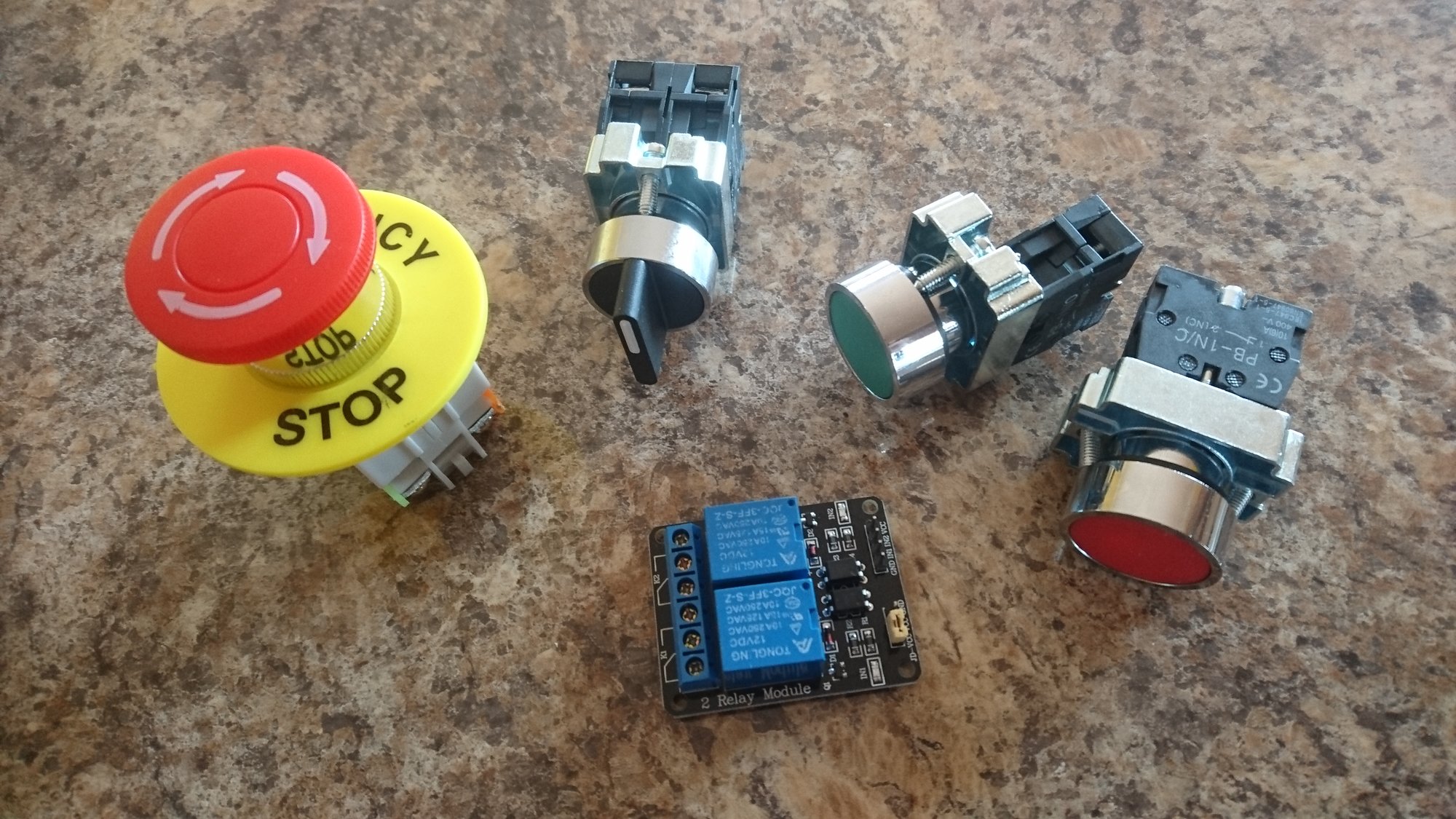

Few more bits turned up. Some switches for the control panel and a relay module. This will be used to implement some external logic enabling a centre off position between the forward and reverse selections.

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray

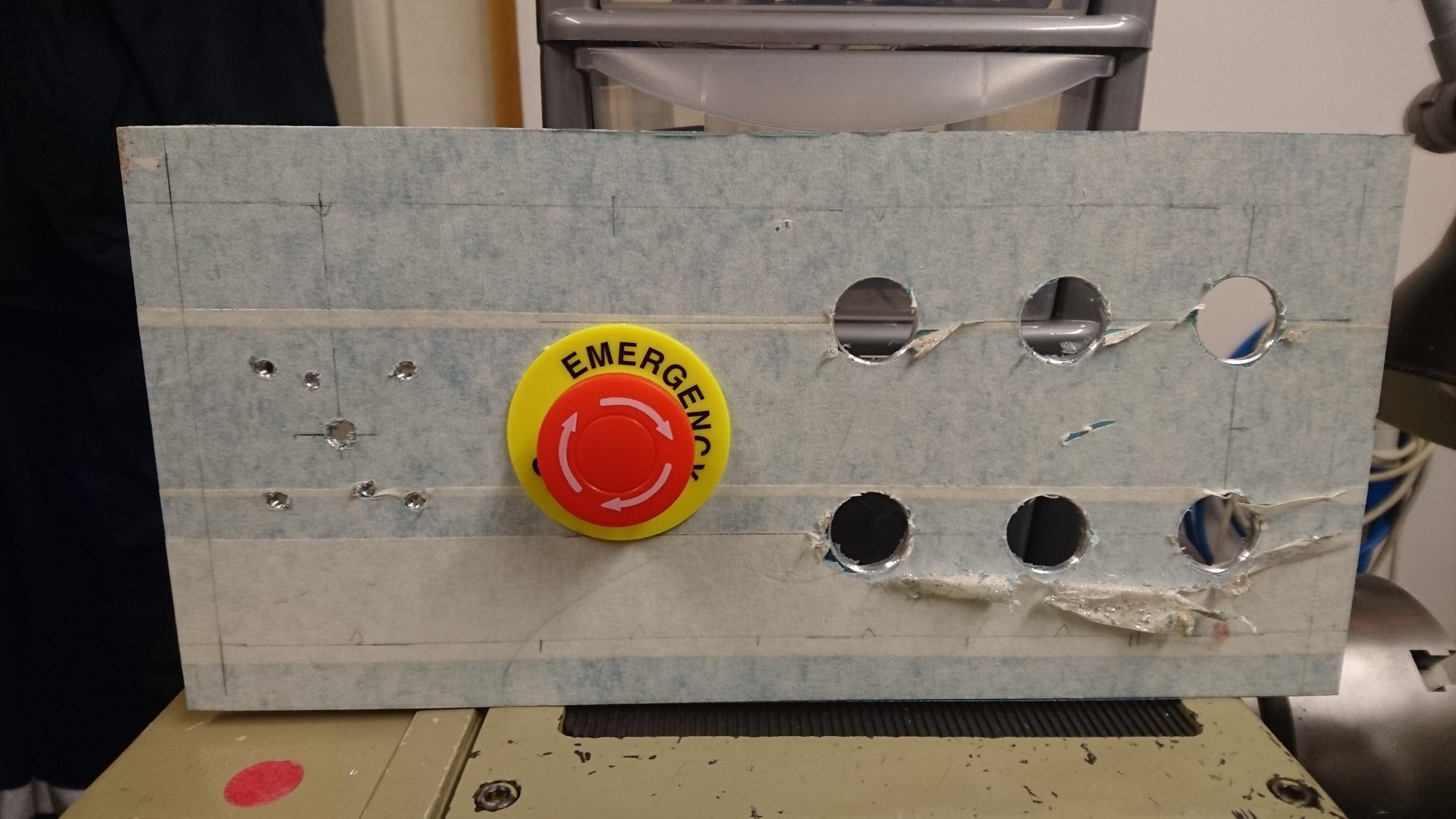

You might have seen the recent posts about my new mill. I said there that I need to crack on with the vfd conversion.

This evening I've spent a couple of hours roughing out the control panel. This is a piece of 3.25 mm thick aluminium that will take the place of the old controls.

The panel is drilled for a main isolator, e stop, two switches for forward/reverse and the suds pump as well as the stop and start buttons. Second picture shows the layout of the controls.

This evening I've spent a couple of hours roughing out the control panel. This is a piece of 3.25 mm thick aluminium that will take the place of the old controls.

The panel is drilled for a main isolator, e stop, two switches for forward/reverse and the suds pump as well as the stop and start buttons. Second picture shows the layout of the controls.

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray

You all know the saga with the new mill. I decided to get myself a cheap insulation tester to check out the motors on it. It's not bad for £30. Does continuity, resistance and Ac/Dc volts too. Insulation to 1000 volts.

Anyway, I was showing my youngest son how to do continuity checks and found one of my industrial switches is open circuit. New one coming tomorrow!

Anyway, I was showing my youngest son how to do continuity checks and found one of my industrial switches is open circuit. New one coming tomorrow!

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray

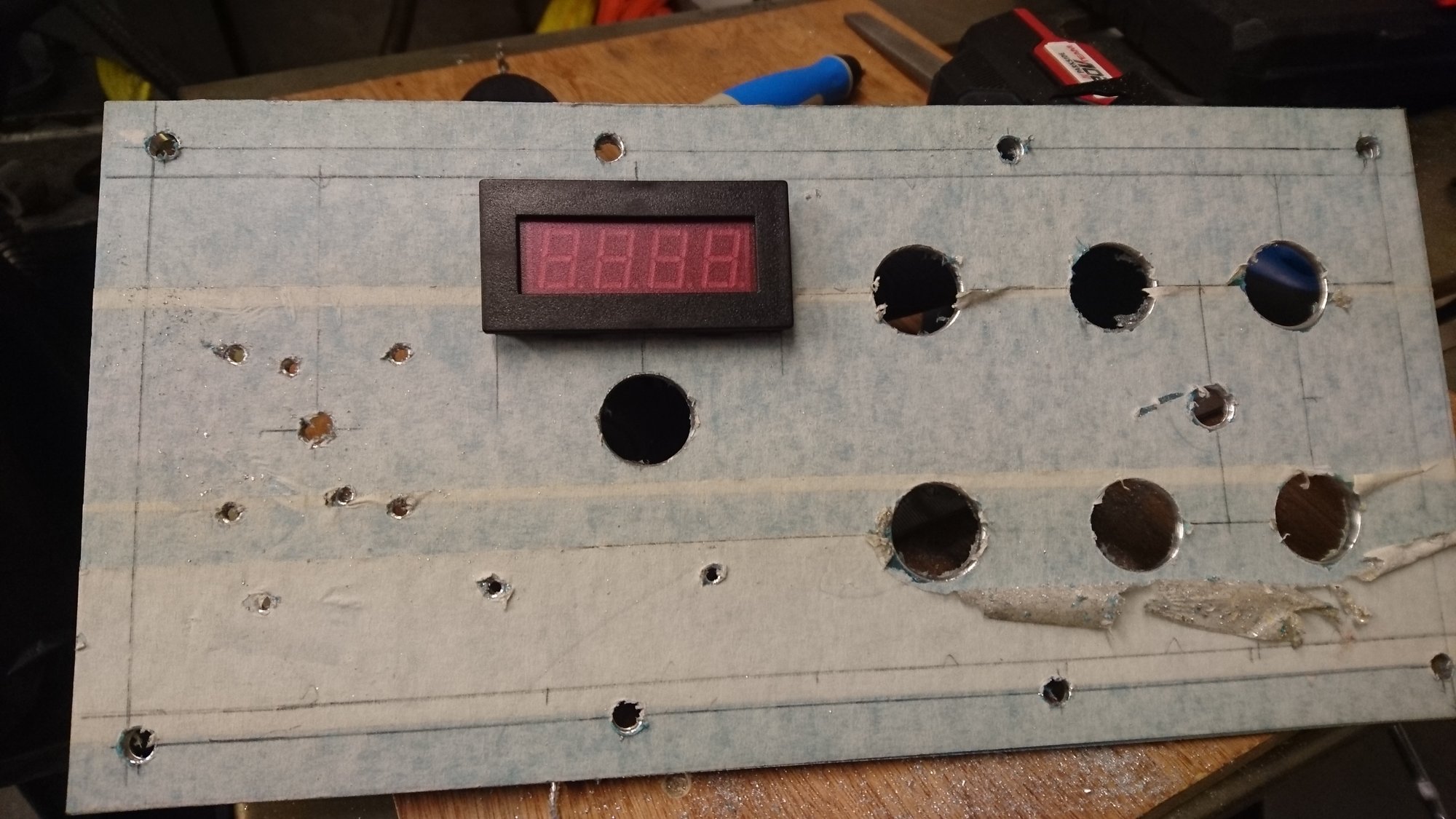

Making the cut out for the LED RPM display.

The panel is basically ready to be painted now.

The panel is basically ready to be painted now.

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray

Yes, really. I know. Not made by Megger, granted, but it will be good enough for my purposes.

Carl Wilson

Member

- Messages

- 2,010

- Location

- Moray