Erie Fred

Member

- Messages

- 6,378

- Location

- Erie, Pa USofA

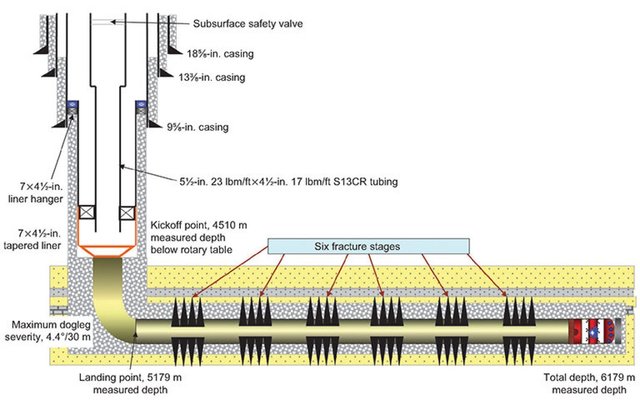

Uhm....Fracking sand is used, allot of fracking sand is shoved down there with thousands of gallons of water, along with proprietary ingredients.When a well is drilled, the oil bearing zone cuttings and rock structure are analysed. Once the well is complete different casing types at the oil inlet end are used. Some are a gravel pack, so simplistically gravel packed around the tubing to allow oil and gas to flow, but hold back rock. Others if its likely to produce lots of sand would have sand screen, where the oil bearing end of the tubing is wrapped in fine very strong hard wearing wire, creating a filter to hold sand back but allow oil and gas to flow.

If when starting a well up, especially a newly completed one, you need to bring them on slowly or the screen can collapsed. If you've 5000 psi or more at the well head, the sand particles rattling through the choke will be moving really quickly, cutting the choke to bits. The choke is the valve that is used to regulate the fluid flow. All the other valves in the xmas tree on the well head are open or close. Once the choke is cut, control is lost, so the well would be shut in until its replaced.

Down hole tubing design is quite specialised not something the piping guys would get involved with. Drilling folk do down hole and stop once the xmas tree is installed. Piping guys work from the choke. The pipe spec regardless of whats in the line is always at the maximum potential pressure. Theres usually coupons to monitor for corrosion and erosion rates, also ndt on the bends or other high wear areas.

That I do know.

A screen would not allow it to get down there eh ?

"Hydraulic fracturing requires drillers to pump large amounts of water mixed with sand or other proppants into the shale formation under high pressure (approximately 10,000 psi) to fracture the shale formation adjacent to the wellbore and to create paths that connect the gas to the well. This allows the natural gas to flow freely up the well for compression, transmission, and sale. Once the hydraulic fracturing process is completed and the wellbore pressure is released, approximately onethird of the water flows out of the well11. That hydraulic fracturing flowback water (HFFW) must be treated to remove chemicals and minerals.1 Horizontal wells in the Marcellus Shale require 3 to 5 million gallons for hydraulic fracturing, whereas conventional wells of a similar depth required approximately 1 million gallons of water.10 The greater quantity of water used for fracturing in shale gas wells is due in part to the extended reach of horizontal wells in addition to the amount of fracturing required to extract gas from a rock that has low permeability11."

it seemed far easier pull forward keyhole then back and let it fill and they were relatively cheap around £35 for 8kg iirc. so 6011 should be similar

it seemed far easier pull forward keyhole then back and let it fill and they were relatively cheap around £35 for 8kg iirc. so 6011 should be similar